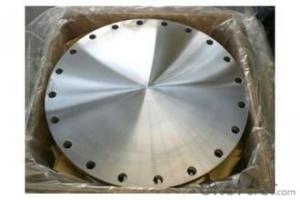

STAINLESS STEEL PIPE FORGED FLANGES 304/316 ANSI B16.5 BEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Flange:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Flange:

ANTI-RUST OIL

Marking Of Stainless Steel Flange:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Flange:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Flange:

Carbon Steel Flange Slip On Flange, Plate Flange, Blind Flange, Welding Neck Flange, Socket Welded Flange, Thread Flange, Lap Joint Flange, Long Welding Neck Flange

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Flange |

| Size | 1/2" - 48" |

| Face | RF, FF, RTJ |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.5, B16.47, BS4504, JIS B2220, API 6A, 11Detc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STAMDARD Of Stainless Steel Flange

<table style="WIDTH: 838px" cellspaci

- Q: What are the common uses of stainless steel pipes?

- Stainless steel pipes are widely used in various industries for a multitude of applications. Some of the common uses of stainless steel pipes include: 1. Plumbing and Water Supply: Stainless steel pipes are often used in residential, commercial, and industrial plumbing systems due to their corrosion resistance, durability, and ability to handle high-pressure applications. They are also used in water treatment plants and wastewater management systems. 2. Oil and Gas Industry: Stainless steel pipes are extensively used in the oil and gas industry for transporting oil, gas, and other fluids. They can withstand high temperatures, pressure, and corrosive environments, making them ideal for this industry. 3. Food and Beverage Industry: Stainless steel pipes are widely used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are commonly used for transporting liquids, gases, and food products in processing plants, breweries, wineries, dairies, and other food-related facilities. 4. Chemical and Petrochemical Industry: Stainless steel pipes are critical in the chemical and petrochemical industry, where they are used for transporting corrosive chemicals, acids, and other hazardous substances. The pipes' resistance to corrosion and high temperatures makes them suitable for these demanding applications. 5. Construction and Architecture: Stainless steel pipes are used in construction and architecture for various purposes such as structural support, handrails, guardrails, and decorative elements. Their strength, durability, and aesthetic appeal make them a popular choice in modern architectural designs. 6. Automotive and Transportation: Stainless steel pipes are used in the automotive industry for exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion. They are also used in the transportation of fluids and gases in ships, trains, and airplanes. 7. Pharmaceutical Industry: The pharmaceutical industry requires high-quality materials that meet stringent sanitary standards. Stainless steel pipes are commonly used in pharmaceutical manufacturing processes for transporting liquids, gases, and chemicals due to their cleanability, corrosion resistance, and compatibility with pharmaceutical products. 8. Power Generation: Stainless steel pipes are used in power plants, both conventional and renewable, for various applications such as steam lines, condensers, and heat exchangers. They are chosen for their ability to withstand high temperatures, pressure, and corrosive environments. In summary, stainless steel pipes find applications in a wide range of industries including plumbing, oil and gas, food and beverage, chemical and petrochemical, construction, automotive, pharmaceutical, and power generation. Their corrosion resistance, durability, and ability to handle high temperatures and pressure make them a versatile and reliable choice for various industrial applications.

- Q: Can steel pipes be used for underground cooling systems?

- Yes, steel pipes can be used for underground cooling systems. Steel pipes are commonly used in various applications, including underground cooling systems, due to their durability, strength, and resistance to corrosion. They can effectively handle the high pressure and temperature demands of cooling systems. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance. However, it is important to ensure that the steel pipes are properly coated or insulated to prevent corrosion and maintain efficiency in heat transfer.

- Q: How are steel pipes transported and stored?

- Steel pipes are typically transported using trucks, trains, or ships, depending on the distance and quantity. These pipes are often stacked and secured with straps or chains during transportation to prevent any movement or damage. When it comes to storage, steel pipes are commonly stored in outdoor yards or warehouses. They are usually organized in neat rows or stacked on racks to maximize space and facilitate easy access. Additionally, pipes may be covered with weather-resistant materials to protect them from rust or corrosion during storage.

- Q: Are steel pipes suitable for underground chemical transport?

- Steel pipes are generally considered suitable for underground chemical transport due to their high strength and durability. Steel pipes can withstand the pressure and weight of the soil above them, making them resistant to damage or collapse. Additionally, steel pipes are corrosion-resistant, which is crucial when transporting chemicals that may react with or corrode other materials. They are also able to handle a wide range of temperatures, making them suitable for transporting chemicals that may require specific temperature conditions. However, it is important to consider the specific chemical being transported and consult with experts in chemical engineering or pipeline design to ensure that the steel pipes are compatible with the chemical and that any necessary safety measures are in place.

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are known for their high strength and durability, making them suitable for carrying steam at high temperatures and pressures. Additionally, steel pipes have excellent thermal conductivity, allowing for efficient heat transfer during steam distribution.

- Q: How are steel pipes protected against lightning strikes?

- Steel pipes are protected against lightning strikes by installing lightning rods or grounding systems on top of the structures where the pipes are located. These systems help to divert the electrical discharge from lightning strikes, reducing the risk of damage to the steel pipes.

- Q: What is the weight and strength of steel pipes?

- Steel pipes can vary in weight and strength depending on their dimensions and the specific grade of steel used. The weight of steel pipes is typically measured in pounds per foot or kilograms per meter. The strength of steel pipes is commonly measured in terms of its yield strength and ultimate tensile strength. The weight of steel pipes can range from a few pounds per foot for smaller sizes to several hundred pounds per foot for larger diameters and thicker walls. The weight is influenced by factors such as the pipe's outer diameter, wall thickness, and length. For example, a 1-inch diameter steel pipe with a wall thickness of 0.125 inches may weigh around 0.67 pounds per foot, while a 12-inch diameter steel pipe with a wall thickness of 0.5 inches can weigh around 142 pounds per foot. The strength of steel pipes is determined by the grade of steel used, which can vary depending on the application and specific requirements. Common grades of steel used for pipes include ASTM A53 for general-purpose applications, ASTM A106 for high-temperature service, and API 5L for oil and gas transportation. These grades have different yield strengths and ultimate tensile strengths. Yield strength refers to the amount of stress a steel pipe can withstand before it begins to deform plastically. It is usually measured in pounds per square inch (psi) or megapascals (MPa). For example, ASTM A53 Grade B steel pipe has a minimum yield strength of 35,000 psi (240 MPa), while API 5L Grade X65 steel pipe has a minimum yield strength of 65,000 psi (448 MPa). Ultimate tensile strength, on the other hand, is the maximum stress a steel pipe can withstand before it fractures. It is also measured in psi or MPa. For instance, ASTM A106 Grade B steel pipe has an ultimate tensile strength of 60,000 psi (415 MPa), whereas API 5L Grade X65 steel pipe has an ultimate tensile strength of 77,000 psi (531 MPa). In summary, the weight and strength of steel pipes can vary depending on their dimensions and the grade of steel used. The weight is influenced by factors such as the pipe's diameter, wall thickness, and length, while the strength is determined by the steel's yield strength and ultimate tensile strength.

- Q: What are the common applications of steel pipes in industrial settings?

- Steel pipes are commonly used in industrial settings for various applications such as transporting fluids and gases, providing structural support in construction projects, conveying materials in manufacturing processes, and facilitating the distribution of water, oil, and gas in pipelines.

- Q: What are the different methods of joining steel pipes without welding?

- There are several methods of joining steel pipes without welding, including: 1. Mechanical Couplings: These couplings consist of two separate pieces that are attached to the ends of the pipes and then tightened together. They provide a secure and leak-proof connection without the need for welding. 2. Threaded Connections: In this method, the ends of the steel pipes are threaded to create a male and female connection. The pipes are then screwed together using pipe threads, providing a strong and reliable joint. 3. Flanged Connections: Flanges are used to connect steel pipes by bolting them together. The flanges have a flat surface with holes that align with corresponding holes in the opposite flange. Bolts are then inserted and tightened to create a tight seal. 4. Grooved Connections: This method involves grooving the ends of the steel pipes and then using grooved couplings to join them. The couplings have teeth that interlock with the grooves, creating a secure and rigid connection. 5. Compression Fittings: Compression fittings are used to join steel pipes by compressing a metal or plastic ring onto the pipe's outer surface. This creates a tight seal and a reliable connection, without the need for welding. 6. Adhesive Bonding: Special adhesives designed for metal bonding can be used to join steel pipes. The adhesive is applied to the surfaces of the pipes, which are then pressed together and left to cure, creating a strong and durable bond. 7. Clamping: Clamps can be used to hold steel pipes together, creating a temporary connection. This method is commonly used for testing purposes or in situations where the pipes need to be easily disassembled. Each of these methods has its own advantages and limitations, and the choice depends on factors such as the specific application, pipe material, and the required strength of the joint.

- Q: Are steel pipes suitable for high-pressure applications?

- Yes, steel pipes are highly suitable for high-pressure applications. Steel is known for its strength and durability, making it an ideal material for carrying fluids or gases under high pressure. Steel pipes have the ability to withstand extreme conditions and maintain their structural integrity, making them a reliable choice for various industries such as oil and gas, chemical processing, and power generation.

Send your message to us

STAINLESS STEEL PIPE FORGED FLANGES 304/316 ANSI B16.5 BEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords