Stainless Steel Hot Rolled Sheet And Slab And Plates Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

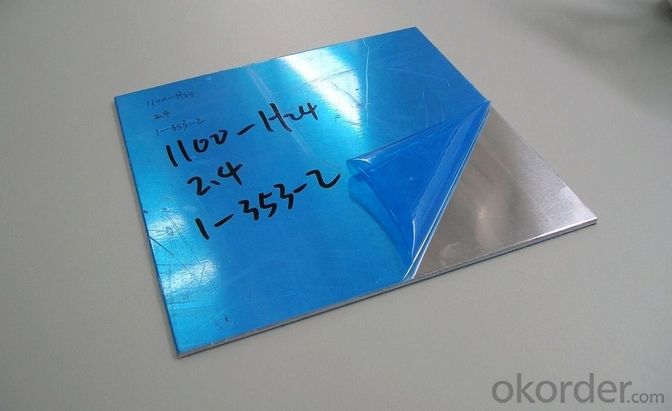

1.Structure of Product Description

Cold rolled Stainless steel sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Yes, stainless steel sheets can be used for swimming pool installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in swimming pools. It is resistant to rust, stains, and chemicals commonly found in pool water, making it a reliable choice for long-term use. Stainless steel sheets are often used for pool walls, floors, and other structural components because they can withstand the harsh conditions associated with pool environments. Additionally, stainless steel has a sleek and modern appearance, adding to the overall aesthetics of the pool.

- Q: Are stainless steel sheets suitable for storage tanks?

- Yes, stainless steel sheets are suitable for storage tanks. Stainless steel is a highly durable and corrosion-resistant material, making it an ideal choice for storing various substances. It offers excellent resistance to rust and corrosion, ensuring that the tank remains intact and free from leaks. Stainless steel also has a high strength-to-weight ratio, allowing for the construction of large storage tanks without sacrificing structural integrity. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for storing food-grade or pharmaceutical substances. Overall, stainless steel sheets are a reliable and long-lasting option for storage tanks in various industries.

- Q: What are the different types of stainless steel sheet patterns?

- There are several different types of stainless steel sheet patterns, including plain, diamond, honeycomb, chequered, and linen. These patterns offer various aesthetic options for different applications and design preferences.

- Q: Are stainless steel sheets suitable for decorative applications?

- Yes, stainless steel sheets are suitable for decorative applications. Stainless steel is a versatile material that offers both durability and aesthetic appeal, making it ideal for various decorative purposes. It is commonly used in interior design, architecture, and furniture manufacturing due to its sleek and modern look. Stainless steel sheets can be shaped, cut, and fabricated into different patterns, textures, and finishes, allowing for endless design possibilities. Whether it is for wall cladding, backsplashes, countertops, or decorative accents, stainless steel sheets can enhance the visual appeal of any space. Additionally, stainless steel is resistant to corrosion, staining, and heat, ensuring its long-lasting beauty even in challenging environments.

- Q: What is the thermal expansion rate of stainless steel sheets?

- The thermal expansion rate of stainless steel sheets varies depending on the specific grade of stainless steel and the temperature range in which it is exposed. Generally, stainless steel has a coefficient of thermal expansion (CTE) of around 10-17 x 10^-6 per degree Celsius (µm/m°C). This means that for every degree Celsius increase in temperature, the stainless steel sheet will expand by 10-17 micrometers per meter of length. It is important to note that the CTE can vary slightly for different grades of stainless steel, so it is recommended to consult the manufacturer's specifications or engineering handbooks for more precise information on the thermal expansion rate of a particular stainless steel sheet.

- Q: How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q: What is the function of a stainless steel plate at the top of the steel chimney?

- According to some characteristic elements of main chemical components in steel or steel in the classification, divided into chromium stainless steel, chromium nickel stainless steel, nickel chromium molybdenum stainless steel and low carbon steel, stainless steel, stainless steel and high molybdenum high purity; according to the characteristics and application of classification of steel, stainless steel, divided into nitric acid resistant stainless steel, high resistance to sulfuric acid pitting resistance to stress corrosion of stainless steel, stainless steel, stainless steel and other steel; according to the classification features, divided into low temperature stainless steel, non-magnetic stainless steel, stainless steel, stainless steel, free cutting superplasticity.

- Q: What is the difference between 304 and 316 stainless steel sheets?

- Both 304 and 316 stainless steel sheets are popular options for a wide range of uses because of their exceptional durability and ability to resist corrosion. However, there are some important differences to note. Firstly, the composition of these stainless steel alloys is the most noticeable distinction. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. The added molybdenum in 316 stainless steel enhances its resistance to corrosion, particularly in chloride-rich environments like marine or coastal areas. Therefore, 316 stainless steel is often preferred for applications where exposure to harsh conditions or corrosive chemicals is anticipated. Secondly, the higher nickel and molybdenum content in 316 stainless steel make it more resistant to pitting and crevice corrosion, which can occur in stagnant or low-oxygen environments. This makes 316 stainless steel a better choice for applications that involve prolonged exposure to acidic or alkaline solutions, such as chemical processing plants or medical equipment. Thirdly, the higher molybdenum content in 316 stainless steel also improves its ability to withstand high temperatures. It can endure higher temperatures than 304 stainless steel, making it suitable for applications that involve exposure to heat, such as exhaust systems or boilers. Lastly, 316 stainless steel is generally more expensive than 304 stainless steel due to its higher alloy content. However, the added benefits and increased resistance to corrosion of 316 stainless steel may justify the higher cost in specific applications where performance and longevity are crucial. In conclusion, while both 304 and 316 stainless steel sheets offer exceptional resistance to corrosion, 316 stainless steel provides superior resistance to challenging environments, acidic or alkaline solutions, and higher temperatures due to its higher nickel, chromium, and molybdenum content. The choice between the two will depend on the specific application and the level of corrosion resistance required.

- Q: What is the maximum thickness available for stainless steel sheets?

- The maximum thickness available for stainless steel sheets can vary depending on the specific grade of stainless steel and the manufacturing capabilities of the supplier. However, in general, stainless steel sheets can be found in thicknesses ranging from 0.5mm to 80mm. It is important to note that thicker sheets are typically used for specialized applications that require increased strength and durability, such as construction projects or heavy machinery. When selecting stainless steel sheets, it is crucial to consider the intended use and consult with a reputable supplier to ensure that the desired thickness is available.

- Q: Are stainless steel sheets resistant to chemicals?

- Yes, stainless steel sheets are generally resistant to chemicals. Due to their high levels of chromium and nickel, stainless steel sheets exhibit excellent resistance to corrosion from a wide range of chemicals, making them suitable for various industrial and commercial applications.

Send your message to us

Stainless Steel Hot Rolled Sheet And Slab And Plates Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords