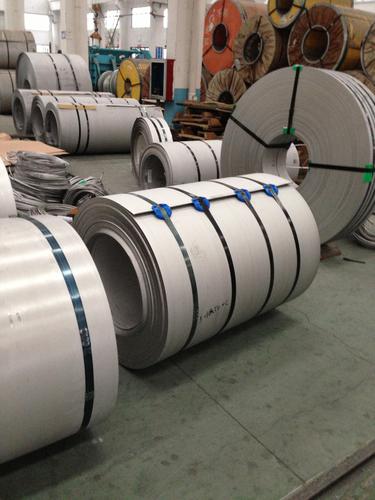

Stainless Steel Plate Cold Rolled And Hot Rolled Stocks

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled AND HOT ROLLED aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, BANGLADESH, SRI LANKA, VIETNAM,

INDONEVISA, ETC.

SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, SS SHEET,PPGI,GI.

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- Stainless steel punching net is a kind of metal plate net made of stainless steel plate punched by punching machine according to certain pass and mould. Common material: stainless steel punching mesh, divided into several materials, there are 201, 304, 321, 316 and 316L.

- Q: How do you remove scratches from stainless steel sheets?

- To remove scratches from stainless steel sheets, there are a few methods you can try. First, you can start by using a non-abrasive cleaner or a mild detergent mixed with warm water. Apply the solution to the scratched area using a soft cloth or sponge, and gently rub in a circular motion. Rinse the area thoroughly and dry it with a clean cloth. If the scratches are still visible, you can try using a stainless steel scratch removal kit. These kits often contain a polishing compound specifically designed for stainless steel. Apply the compound to the scratched area and use a soft cloth to buff the surface in the direction of the grain. Continue buffing until the scratches are no longer visible. For deeper scratches, you may need to use a fine-grit sandpaper or a stainless steel scratch repair pen. Start by lightly sanding the scratched area in the direction of the grain. Be careful not to apply too much pressure, as this can damage the surface. After sanding, clean the area thoroughly and use a polishing compound to restore the shine. It's important to note that these methods may not completely remove deep scratches, and in some cases, a professional repair may be necessary. Additionally, always test any cleaning or repair method on a small, inconspicuous area before applying it to the entire surface to ensure it does not cause further damage.

- Q: What is the corrosion resistance of stainless steel sheets in saltwater?

- Stainless steel sheets have excellent corrosion resistance in saltwater environments. The high levels of chromium present in stainless steel enable the formation of a passive oxide layer on the surface, which acts as a protective barrier against corrosion. This oxide layer is highly resistant to saltwater, preventing the metal from being directly exposed to the corrosive effects of the saltwater. Additionally, stainless steel alloys such as 316 and 316L contain molybdenum, which further enhances their resistance to pitting and crevice corrosion in saltwater. Overall, stainless steel sheets are a preferred choice for applications in saltwater environments due to their exceptional corrosion resistance properties.

- Q: Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is highly resistant to corrosion, making it an ideal material for outdoor applications. It can withstand exposure to various weather conditions, including rain, humidity, and sunlight, without rusting or deteriorating. Additionally, stainless steel's strength and durability ensure that it can withstand the pressure and weight typically exerted on railings, making it a reliable choice for outdoor installations.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Yes, stainless steel sheets are suitable for elevator control panels. Stainless steel is a durable and resistant material that can withstand various environmental conditions, including frequent use and exposure to moisture, heat, and chemicals. Elevator control panels often require a material that is easy to clean, resistant to scratches and dents, and aesthetically pleasing. Stainless steel meets all these criteria, making it an ideal choice for elevator control panels. Additionally, stainless steel has a sleek and modern appearance, which can enhance the overall design of the elevator interior.

- Q: Can stainless steel sheets be used for decorative screens?

- Yes, stainless steel sheets can be used for decorative screens. Stainless steel is a versatile material that can be easily manipulated into various shapes and designs, making it suitable for decorative purposes. Its durability, resistance to corrosion, and aesthetic appeal make it a popular choice for creating decorative screens in homes, offices, and other spaces.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer several benefits. Firstly, they provide a sleek and modern aesthetic appeal, making them a popular choice for interior and architectural design. Additionally, the reflective surface of these sheets creates the illusion of a larger space, making them ideal for small areas. Mirror-finish stainless steel also has superior corrosion resistance, making it a durable option for outdoor applications. The smooth surface is easy to clean and maintain, reducing the need for frequent upkeep. Finally, mirror-finish stainless steel sheets are often used in food processing and medical industries due to their hygienic properties and ability to resist bacterial growth.

- Q: How do I bend or form stainless steel sheets?

- To bend or form stainless steel sheets, you can follow these steps: 1. Choose the appropriate stainless steel grade: Stainless steel comes in various grades, each with specific properties. Select the grade that best suits your project's requirements, considering factors like corrosion resistance, strength, and formability. 2. Use the right tools: To bend stainless steel sheets, you will need specific tools such as a hydraulic press brake or a metal bending machine. These tools apply force evenly to achieve precise and consistent bends. Make sure to use tools that are designed for stainless steel to avoid damaging the material. 3. Prepare the stainless steel sheet: Before bending, ensure that the stainless steel sheet is clean and free from any dirt or debris. Additionally, mark the desired bending lines on the sheet using a pencil or tape to guide you during the process. 4. Determine the bending angle and radius: Determine the angle and radius of the bend you want to achieve. This will depend on the specific requirements of your project. Use a protractor or a template to measure and mark the desired angles accurately. 5. Secure the stainless steel sheet: To prevent movement or slipping during the bending process, securely clamp the stainless steel sheet to the bending tool or machine. This will ensure stability and accuracy during the bending process. 6. Apply pressure gradually: Start the bending process slowly and gradually increase the pressure. This prevents the stainless steel sheet from cracking or warping. Monitor the bending carefully to ensure that the desired shape is achieved without any defects or deformation. 7. Repeat if necessary: If you need to create multiple bends or complex shapes, repeat the process as required. Ensure that each bend is carefully measured and aligned with the previous bends to achieve a consistent and accurate result. 8. Finishing touches: After bending the stainless steel sheet, remove any residual marks or burrs using a file or sandpaper. This will give your finished product a smooth and polished appearance. Remember, bending stainless steel sheets can be challenging, especially for thicker gauges or harder grades. It is advisable to practice on scrap pieces or seek professional assistance if you are unsure or lack experience in working with stainless steel.

- Q: What is the price range for stainless steel sheets?

- The cost of stainless steel sheets can fluctuate based on several factors, including the thickness, size, and grade of the stainless steel. Typically, thinner sheets begin around $30 per square foot, while thicker or higher-grade sheets can reach up to $150 per square foot. It is crucial to consider that market conditions and supplier pricing policies may also impact prices. Thus, it is advisable to compare prices from various suppliers before finalizing a purchase.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets possess numerous advantages that distinguish them from alternative metal sheets. Firstly, stainless steel exhibits a high level of resistance to corrosion, rendering it an optimal selection for applications where durability and longevity are of utmost importance. Unlike other metals, stainless steel does not readily rust or stain, thereby guaranteeing the preservation of its appearance and functionality even in challenging environments. Secondly, stainless steel sheets are renowned for their strength and robustness. They possess a significant tensile strength, enabling them to endure heavy loads without undergoing bending or warping. This attribute renders stainless steel sheets suitable for a wide array of applications, including the construction, automotive, and manufacturing industries. Another notable advantage of stainless steel sheets lies in their hygienic properties. Stainless steel is non-porous and non-absorbent, facilitating easy cleaning and maintenance. Additionally, it exhibits resistance to bacterial growth, making it a favored choice for medical equipment, food processing facilities, and kitchen appliances. Furthermore, stainless steel sheets offer exceptional heat resistance. They can withstand high temperatures without compromising their structural integrity or developing any deformities, making them suitable for applications involving extreme heat or thermal cycling. Lastly, stainless steel sheets are available in a variety of finishes and textures, granting versatility in terms of design options. Whether one prefers a polished, brushed, or matte finish, stainless steel allows for customization to fulfill any aesthetic requirement. In conclusion, stainless steel sheets surpass other types of metal sheets due to their exceptional resistance to corrosion, strength, hygienic properties, heat resistance, and aesthetic versatility. These qualities establish stainless steel sheets as the preferred choice for numerous industries, ensuring durability, reliability, and longevity across various applications.

Send your message to us

Stainless Steel Plate Cold Rolled And Hot Rolled Stocks

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords