Stainless Steel Coil Cold Rolled 201 Half Hard Surface No.2E with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni.

The steel has good corrosion resistance and hot / cold processing performance, instead

of 304 stainless steel products for used in the not high of corrosive environment, such as

indoor, inland city outdoor etc.

2. Main Features of the Stainless Steel Coil Cold Rolled 201

Product name: Stainless Steel Coil Cold Rolled 201

Thickness: 0.2mm to 1.5mm

Technical: Cold Rolled

Width: 10mm to 1240mm

Type: 200 Series

Length: As customer's requested

Standard: JIS, SUS, AISI, ASTM

Grade: 201-J1, 201-J4, AISI201, AISI202…

Finish: BA, 2B, 8K, NO.3, NO.4, HL…

MOQ: 25 Metric Tons

Hardness: Low Hard(190 HV Max); Half Hard(240-280HV); Full Hard(42-60 HRC)

Ship Term: FOB any port, China or CFR Destination port

Delivery Time: 15 to 20 day after the receive the deposit or 100%LC

Payment Terms: TT 30% for deposit, Balance against the copy of B/L, or 100%LC

Packaging: By wooden pallet, wooden case or according to customer's request

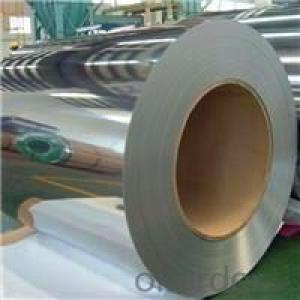

3. Stainless Steel Coil Cold Rolled 201 Images

4. Stainless Steel Coil Cold Rolled 201 Specifications

Stainless Steel 200 Series Chemicals Contrast (wt. %) | ||||||||

Chemicals | C | Si | Mn | Cr | Ni | N | Other | |

205 | 0.12-0.25 | ≤0.75 | 14.0-15.0 | 16.5-18.0 | 1.0-1.75 | 0.32-0.4 | ||

JIS, | 201 | ≤0.15 | ≤1.0 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - |

201L | ≤0.03 | ≤0.75 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | 17.0-19.0 | 4.0-6.0 | ≤0.25 | - | |

201LN | ≤0.03 | ≤0.75 | 6.4-7.5 | 16.0-17.5 | 4.0-5.5 | 0.1-0.25 | Cu≤1.0 | |

India | 201-J1 | ≤0.08 | ≤0.75 | 7.0-8.0 | 15.0-17.0 | 4.0-5.0 | ≤0.1 | Cu≤1.5 |

201-J3 | ≤0.08 | ≤0.75 | 9.0-10.5 | 14.0-16.0 | 2.0-3.0 | ≤0.15 | Cu≤2.0 | |

201-J4 | ≤0.10 | ≤0.75 | 8.5-10.0 | 15.0-16.0 | ≤1.2 | ≤0.2 | Cu≤2.0 | |

America | 204 | ≤0.03 | ≤1.0 | 7.0-9.0 | 15.0-17.0 | 1.5-3.0 | 0.15-0.3 | (Cu) |

H400 | ≤0.10 | ≤1.0 | 6.0-9.0 | 17.0-19.5 | ≤3.5 | ≤0.3 | - | |

Japan | YUS130S | 0.09 | 0.5 | 11.0 | 18.0 | 6.5 | 0.35 | - |

NTK S-4 | 0.17 | 0.43 | 14.7 | 17.7 | 1.3 | 0.35 | - | |

NM15M | 0.08 | 0.8 | 14.5 | 17.0 | 4.3 | 0.33 | - | |

Europe America | 219 | ≤0.04 | ≤0.75 | 8.0-10.0 | 19.0-21.5 | 5.5-7.5 | 0.15-0.4 | - |

Cromanite | ≤0.08 | ≤1.0 | 9.5-11.0 | 18.0-20.0 | ≤1.0 | 0.4-0.6 | - | |

201 Surface | Characteristic and Application of Stainless Steel Coil Cold Rolled 201 |

2B | The surface brightness and flatness of 2B is better than 2D then through a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.4 | Polished with abrasive belt of grit#150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and electrical appliances kitchen utensils and food processing. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness like mirror kitchen apparatus, etc. |

8K | The product have excellent brightness and prefer bright can be the mirror. |

5. FAQ of Stainless Steel Coil Cold Rolled 201

Q: Are you factory or trader?

A: We certainly are stainless steel manufacturer and have processing plant.

Q: Can you provide mill test certificate?

A: Yes! Mill test certificate for both hot rolled raw material coils and cold rolled coils are

available.

Q: Can you make DDQ (Deep drawing quality)?

A: Yes. Our material has been widely used for producing stainless steel pots and stainles

s steel sinks, which have strict request for good deep drawing quality.

Q: How to visit your factory?

A: Most of the main cities in the world have flight to Beijing; you can take flight to Beijing

first, then we will lead you to our Wuxi mills.

Q: How about your company?

A world class manufacturer & supplier of castings forging in stainless steel, is one of the

large-scale professional investment casting production bases in China, consisting of both

casting foundry forging and machining factory. Annually more than 90000 tons Precision

casting and forging parts are exported to markets in Europe, America and Japan. OEM

casting and forging service are available, all according to customer’s requirements.

Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every

link from raw material to final product we have strict quality test; We resolutely put an end

to unqualified products flowing into the market. At the same time, we will provide

necessary follow-up service assurance.

Q: How is the packaging and delivery?

A: Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden

box), or as your requirement and the delivery term is based on the project.

Q: How long can we receive the product after purchase?

A: In the purchase of product within 20 working days, we will arrange the factory delivery

as soon as possible. The specific time of receiving is related to the state and position of

customers. Commonly 20 to 40 working days can be served.

- Q: Are stainless steel strips suitable for conveyor belts?

- Yes, stainless steel strips are highly suitable for conveyor belts due to their durability, heat and corrosion resistance, and high strength-to-weight ratio. They can withstand heavy loads, extreme temperatures, and harsh environments, making them an excellent choice for various industries that require reliable and long-lasting conveyor systems.

- Q: Can stainless steel strips be used in the production of oil and gas storage tanks?

- Yes, stainless steel strips can be used in the production of oil and gas storage tanks. Stainless steel is a versatile and durable material that offers excellent corrosion resistance, making it suitable for use in harsh environments such as oil and gas storage tanks. Its high strength-to-weight ratio and resistance to temperature variations also make it an ideal choice for these applications. Additionally, stainless steel is easy to clean and maintain, ensuring the longevity and reliability of the storage tanks.

- Q: Are stainless steel strips suitable for automotive trim applications?

- Yes, stainless steel strips are suitable for automotive trim applications. Stainless steel offers excellent resistance to corrosion, durability, and a sleek appearance, making it an ideal material for automotive trim.

- Q: What are the maximum temperatures stainless steel strips can withstand?

- The maximum temperatures that stainless steel strips can endure are dependent on the particular grade of stainless steel utilized. In general, stainless steel is recognized for its ability to resist high temperatures, making it suitable for a wide array of applications. The commonly employed grades of stainless steel, like 304 and 316, typically possess the capacity to withstand temperatures of up to approximately 1500°F (815°C) without experiencing significant deformation or loss of mechanical properties. Nonetheless, there exist specialized grades of stainless steel, for instance, 310 and 330, which exhibit an even greater resistance to high temperatures, enduring temperatures of around 2100°F (1150°C). It is vital to consider the specific grade and intended application when establishing the maximum temperature that stainless steel strips can bear.

- Q: Can stainless steel strips be used in the brewing industry?

- The brewing industry can indeed utilize stainless steel strips. Stainless steel is widely chosen in the brewing industry because of its durability, resistance to corrosion, and ease of cleaning. Within breweries, stainless steel strips are commonly employed for constructing brewing vessels, fermentation tanks, piping systems, and heat exchangers. By utilizing stainless steel strips, the brewing equipment and components become resistant to the corrosive and acidic nature of brewing ingredients, as well as capable of withstanding high temperatures and pressures. Furthermore, stainless steel is a sanitary material, making it suitable for the food and beverage industry. In summary, stainless steel strips prove to be an excellent option for the brewing industry, presenting a dependable and long-lasting solution for a variety of brewing applications.

- Q: Can stainless steel strips be etched or engraved?

- Yes, stainless steel strips can be etched or engraved using various techniques such as chemical etching, laser engraving, or mechanical engraving.

- Q: How do you determine the corrosion resistance of a stainless steel strip?

- To determine the corrosion resistance of a stainless steel strip, various tests can be conducted. One commonly used method is the salt spray test, where the strip is exposed to a saltwater mist for a specified period. The strip's performance is evaluated by observing any signs of corrosion, such as rust or discoloration. Additionally, electrochemical tests, such as the polarization test or the potentiodynamic scan, can be conducted to measure the strip's corrosion potential and resistance. These tests provide valuable insights into the strip's ability to withstand corrosion in different environments.

- Q: Can stainless steel strips be used for metal stamping?

- Metal stamping can indeed make use of stainless steel strips. Due to their exceptional strength, resistance to corrosion, and long-lasting nature, stainless steel strips enjoy great popularity in metal stamping. They find extensive application in various fields, including automotive parts, appliances, and electrical components. Metal stamping techniques facilitate the easy formation, bending, and stamping of stainless steel strips into diverse shapes and sizes. Thanks to its attributes like hardness and resistance to wear, stainless steel is highly suitable for achieving precise and intricate designs through metal stamping processes. In conclusion, stainless steel strips prove to be an adaptable material that effectively serves the purpose of metal stamping.

- Q: Can stainless steel strips be used in the aerospace landing gear?

- Yes, stainless steel strips can be used in the aerospace landing gear. Stainless steel is a popular material choice for aerospace applications due to its excellent corrosion resistance, high strength, and durability. Landing gear components are exposed to various environmental conditions and stress loads during takeoff, landing, and taxiing, making stainless steel an ideal choice for its ability to withstand these factors. Additionally, stainless steel's resistance to fatigue and impact makes it suitable for withstanding the high loads and shocks experienced during landing and ground operations. Its high strength-to-weight ratio also allows for reduced weight, which is crucial for aerospace applications where weight optimization is a priority. Overall, the use of stainless steel strips in aerospace landing gear provides a reliable and long-lasting solution.

- Q: What are the typical tolerances for stainless steel strips?

- The typical tolerances for stainless steel strips vary depending on the specific requirements of the application and the manufacturing process used. However, in general, the standard industry tolerances for stainless steel strips are typically within a range of +/- 0.005 to 0.010 inches for thickness, and +/- 0.010 to 0.020 inches for width. These tolerances ensure that the stainless steel strips meet the necessary dimensional requirements and can be effectively used in various industries such as automotive, aerospace, and construction. It is important to note that more stringent tolerances can be achieved through specialized manufacturing processes or by utilizing precision equipment and techniques.

Send your message to us

Stainless Steel Coil Cold Rolled 201 Half Hard Surface No.2E with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords