Single Building Hoist New Lifting Machines

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Building Hoist New Lifting Machines

The hoist adopted with the normal electrical control method, is equipped with contactor, control transformer, anti-overheat protector, relay against the phase failure & disorder. All the electrical parts are equipped with Schneider and Siemens products.

The inverter, as a key controlling part, is used in the hoist adopted with VFD+PLC control method. This device is jointly developed by Japan Yaskawa and us. The hardware is supplied by Yaskawa, while the controlling software is supplied by us ensuring safe & reliable operations. PLC controller adopts OMROM products; brake unit is from YASKAWA and other electrical components are from Schneider or Siemens.

With application of VFD, it’s able to realize stepless speed regulating between zero and max speed. There are two shifting-gears set in the operating platform. One is maintenance shift, which can enable the cage run at speed of 0~5M/min for user to check the lubricating condition and connection of the machine’s parts. The other is working shift, enabling the cage with normal working speed. By adopting this control method, it’s also able to check and show the condition of power supply, operation and electrical failure. Moreover, it can avoid misoperation, giving great protection to transmission & electrical system.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

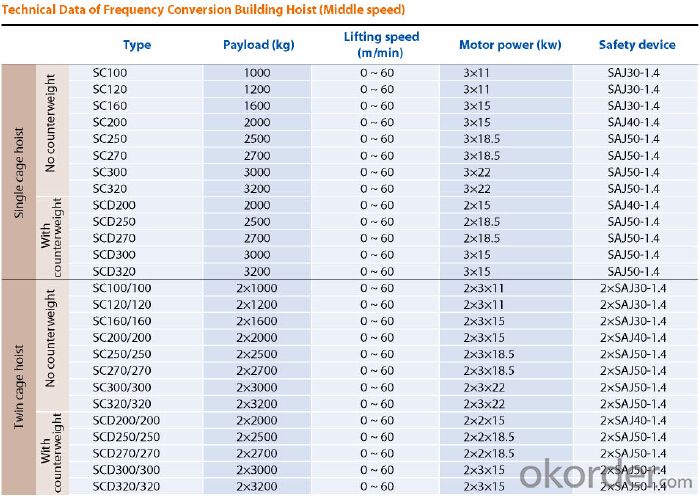

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it permissible to utilize personal lifting gear for the purpose of lifting objects?

- <p>Yes, you can use your own lifting equipment to lift objects, provided it meets safety standards and is suitable for the weight and type of objects being lifted. Always ensure that the equipment is in good working condition, and you are trained in its proper use to prevent accidents. Compliance with local regulations and guidelines is also crucial to avoid any legal repercussions.</p>

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: This question asks for an explanation on how to operate a winch, specifically in the context of a building hoist.

- <p>To use a winch, particularly a building hoist, follow these steps: Ensure the winch is securely anchored and the cable is in good condition. Attach the load to the hook, ensuring it's balanced. Turn the winch handle clockwise to lift the load; counterclockwise to lower it. Always keep tension on the cable to prevent it from slacking. Use a tag line to guide the load horizontally. Never exceed the winch's load limit. Regularly inspect the winch and cable for wear and tear. Always have a spotter to assist and communicate during the operation. Safety is paramount, so never leave the winch unattended while the load is in the air.</p>

- Q: Is it possible to utilize a single-rope lifting system in both indoor and outdoor environments, especially during cold weather?

- <p>Yes, a single-rope lifting system can be used both indoors and outdoors, including in cold weather conditions. However, it's crucial to consider the specific requirements and limitations of the system and the environment. Cold temperatures can affect the strength and flexibility of the rope, as well as the performance of other components like motors and hydraulic systems. It's essential to use appropriate materials designed for low-temperature operation, ensure proper maintenance, and follow safety guidelines to prevent damage or accidents. Always consult the manufacturer's recommendations for operating in extreme weather conditions.</p>

- Q: This question asks whether a hydraulic building hoist can be used in both indoor and outdoor environments and seeks reasons for its versatility.

- <p>A hydraulic building hoist can be used both indoors and outdoors. These hoists are designed to be versatile and durable, capable of withstanding various weather conditions when used outdoors. They are also compact and can be easily maneuvered in indoor spaces. The primary reason for their versatility is the robust construction and the ability to handle different loads with precision. Additionally, hydraulic systems are less affected by electrical interference, making them suitable for environments with fluctuating power supplies. However, it's important to ensure that the hoist is properly maintained and protected from extreme weather conditions to prolong its lifespan and ensure safety.</p>

- Q: Is it possible to operate building hoists in cold weather conditions?

- <p>Yes, building hoists can be used in cold climates, but they must be designed and maintained for such conditions. Cold weather can affect the performance of hoists, so it's crucial to use hoists specifically engineered for low-temperature operation. Regular maintenance and checks are necessary to ensure safety, as extreme cold can cause metal parts to contract and lubricants to thicken, affecting the hoist's functionality. Always follow the manufacturer's guidelines for operating hoists in cold climates.</p>

- Q: Describe the key differences between electric and manual building hoists.

- <p>Electric building hoists are powered by electricity and can lift heavy loads quickly and efficiently. They are automated, reducing manual labor and increasing productivity. On the other hand, manual hoists require human effort to operate, making them slower and less efficient. They are less costly but demand more physical labor, which can lead to fatigue and potential accidents. Electric hoists are suitable for large-scale construction projects, while manual hoists are often used in smaller, more confined spaces where electricity might not be readily available or where the load is not excessively heavy.</p>

- Q: What are alternative uses for a building hoist besides construction?

- <p>Yes, a building hoist can be used for purposes other than construction. It can be utilized for moving heavy equipment in industrial settings, transporting goods in warehouses, or even in emergency services for rescue operations. Its ability to lift and lower heavy loads makes it versatile for various applications where vertical transportation is required. However, it's crucial to ensure that any alternative use complies with safety regulations and the hoist's operational specifications.</p>

- Q: Is it possible to use a lifting device to lift objects that are heavier than its specified maximum load?

- <p>No, a lifting device should never be used to lift objects that exceed its rated load capacity. Doing so can lead to catastrophic failure of the device, potentially causing serious injury or death. Always adhere to the manufacturer's specifications to ensure safety and prevent accidents. Overloading a lifting device can result in structural damage, compromised safety mechanisms, and increased risk of collapse or dropping the load. It is crucial to respect the load limits to maintain the integrity and reliability of the lifting equipment.</p>

- Q: Is it possible to utilize a double-rope lifting mechanism within the context of a building hoist?

- <p>Yes, a double-rope lifting system can be used in a building hoist. This system offers advantages such as increased safety due to redundancy and the ability to lift heavier loads compared to a single-rope system. The double-rope setup allows for the hoist to handle the load with two separate ropes, reducing the risk of failure and providing a more stable lifting platform. It's common in applications where high load capacities and safety are paramount, such as in construction for lifting materials and equipment.</p>

Send your message to us

Single Building Hoist New Lifting Machines

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords