Construction Hoist Single Cage Material Lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

Feature: Construction Hoist Condition: New Application: Construction

Payload(kg):2000 Lifting Speed(m/min):33 Motor Power(kw): 2*11

Safety Device: SAJ40-1.2 Cage: Single Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD200

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

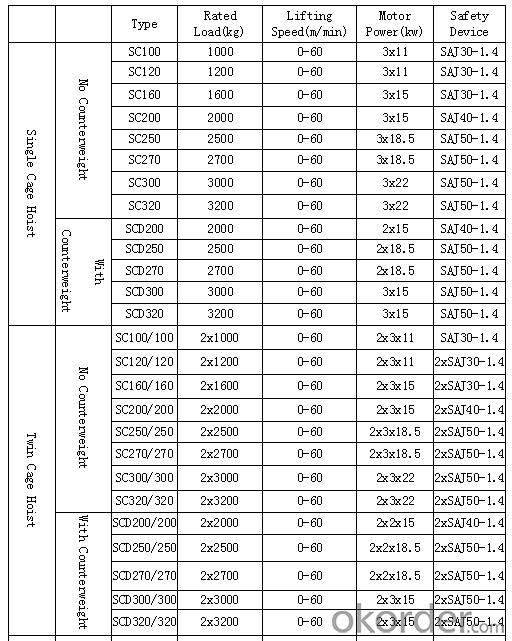

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for a comparison of the pros and cons associated with the use of electric building hoists in construction.

- <p>Electric building hoists offer several advantages such as ease of operation, reduced manual labor, and increased efficiency in lifting and transporting materials. They are also safer compared to manual hoists, reducing the risk of accidents. Additionally, they can handle heavier loads and operate in various weather conditions. However, they have some disadvantages too. For instance, they require a power source and can be less reliable during power outages. They also involve higher initial costs and maintenance expenses. Electric hoists can be noisy, which may lead to noise pollution, and they can be complex to install and operate, requiring skilled personnel.</p>

- Q: Construction elevator positioning should consider which problems

- It is convenient to install the wall with the wall

- Q: The construction elevator always jumps

- The construction elevator of our construction site always jump at the start of the building, always can't find the reason, the reason that can be so, have a person encounter this thing But it used to be normal, and sometimes it's jump, start, jump, start, and sometimes you can do it over and over again,

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: What are the specific safety mechanisms and controls that are typically incorporated into the design of a building hoist to ensure its safe operation?

- <p>Building hoists, also known as construction hoists, are equipped with several safety devices and controls to ensure safe operation. These include limit switches to prevent overtravel, safety locks that engage if the hoist sways excessively, emergency stop buttons for immediate cessation of movement, overload protection to prevent the hoist from lifting more than its capacity, and interlock systems that ensure the hoist cannot operate if a safety gate is open. Additionally, there are guardrails, toe boards, and anti-fall devices to protect workers from falling. Regular inspections and maintenance are also crucial for the safe operation of building hoists.</p>

- Q: Is it possible for a building hoist to lift more than one object simultaneously?

- <p>Yes, a building hoist can lift multiple objects at once, provided the combined weight does not exceed the hoist's maximum load capacity. The hoist's design and specifications will dictate how many and what types of objects can be lifted simultaneously. It's crucial to follow the manufacturer's guidelines to ensure safety and prevent damage to the hoist or the objects being lifted.</p>

- Q: Describe the key differences between electric and manual building hoists.

- <p>Electric building hoists are powered by electricity and can lift heavy loads quickly and efficiently. They are automated, reducing manual labor and increasing productivity. On the other hand, manual hoists require human effort to operate, making them slower and less efficient. They are less costly but demand more physical labor, which can lead to fatigue and potential accidents. Electric hoists are suitable for large-scale construction projects, while manual hoists are often used in smaller, more confined spaces where electricity might not be readily available or where the load is not excessively heavy.</p>

- Q: Is it permissible to utilize electric or hydraulic building hoists in personal workshops or factories?

- <p>Yes, you can use an electric or hydraulic building hoist in your own workshop or factory. However, you must ensure that the hoist complies with local safety regulations and standards. It's crucial to have the hoist installed by qualified professionals and to maintain it regularly to prevent accidents. Always follow the manufacturer's guidelines and safety protocols to ensure the safe operation of the hoist.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of hydraulic lifting equipment.

- <p>Hydraulic lifting equipment offers several advantages, including high force generation, compact design, and precise control. It is energy-efficient and can handle heavy loads with ease. The systems are also known for their durability and low maintenance requirements. However, there are disadvantages such as sensitivity to leaks and the need for regular fluid checks. They can be complex to install and maintain, and the equipment can be costly. Additionally, hydraulic systems are sensitive to temperature changes, which can affect performance.</p>

- Q: How does the construction elevator add up

- You can use a ready-made high-altitude operating platform and a high-altitude working platform

Send your message to us

Construction Hoist Single Cage Material Lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords