Building Hoist Single Cage for Material Transporting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

1. The recommended cage dimension(LXWXH):2.0X1.0X2.5, 2.5X1.0X2.5, 2.5X1.3X2.5, 3.0X1.5X2.5, 3.2X1.5X2.5, 3.8X1.5X2.5, 4.0X1.5X2.5, 4.2X1.5X2.5 etc, we can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to your requirements.

3. The mast and the tie-in surface can adopt paint-spray, or hot galvanizeing processing.

Feature:

There are single cage and double cages hoist. According to the need, getting rid of one cage of double cages-the hoist will be changed to single cage hoist.

SC building hoist is equipped with reliable electrical and mechanical safety device. It is efficient and safety vertical transporting equipment.

FAQ:

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

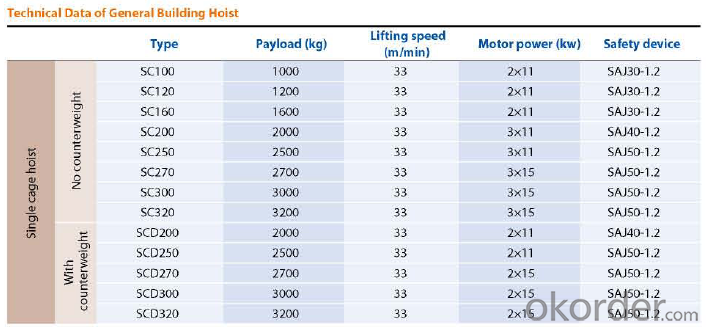

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

In the past 10 years, CNBM has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

Our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

CNBM provides the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of CNBM adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, CNBM guarantee the international first-class level for all of our products.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of CNBM, with branches and spare parts distribution centers established oversea step by step.

In the coming days, CNBM will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all CNBM friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q: Is it possible to utilize a building hoist for the purpose of lifting small tools and equipment?

- <p>Yes, a building hoist can be used for lifting small tools and equipment, provided it is within the hoist's weight capacity. It's important to ensure that the items are securely fastened to prevent any accidents during lifting. Always follow the manufacturer's guidelines and safety regulations when using a building hoist for any lifting tasks.</p>

- Q: This question asks for the methods used to maintain and care for a building hoist, which is a type of lifting equipment used in construction.

- <p>Regular maintenance of a building hoist is crucial for safety and efficiency. Key methods include daily inspections of cables, hooks, and safety devices for any signs of wear or damage. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prevent rust. Ensure that all electrical components are clean and dry, and check for any loose connections or damaged wires. Perform load tests periodically to confirm the hoist's lifting capacity and safety. Keep the control panel and all operational areas clean and free from debris. Regularly check the hoist's anchorage to ensure it is secure. Adhere to all manufacturer's recommendations for maintenance intervals and procedures. Proper maintenance can extend the life of the hoist and prevent accidents.</p>

- Q: This question asks for a comparison of the pros and cons of utilizing hydraulic cylinders in the context of building hoists.

- <p>Hydraulic cylinders in building hoists offer several advantages, including high force output, compact size, and precise control. They provide smooth and controlled lifting, which is crucial for heavy construction materials. Additionally, hydraulic systems can generate large amounts of force with relatively small cylinders, making them space-efficient. The disadvantages include potential leaks, which can be hazardous, and the need for regular maintenance to ensure the system's reliability. Hydraulic systems can also be more complex to install and repair compared to electric or manual systems. Furthermore, they require a constant power source, which might not always be readily available on construction sites.</p>

- Q: This question asks about the process of changing the speed of a building hoist, which is a device used in construction to lift materials.

- <p>Adjusting the speed of a building hoist typically involves accessing the hoist's control panel or motor settings. For electric hoists, this may include adjusting the frequency of the power supply through a variable frequency drive (VFD), which alters the speed of the motor. For manual hoists, speed adjustments might involve changing the gear ratio or the tension on the hoisting rope. Always refer to the hoist's user manual for specific instructions, as different models have different mechanisms. Safety should be a priority; ensure that any adjustments are made by trained personnel and in compliance with safety regulations.</p>

- Q: What are the pros and cons of utilizing hydraulic fluid within the system of a building hoist?

- <p>The advantages of using hydraulic fluid in a building hoist include smooth and controlled lifting, which reduces the risk of accidents. It also offers a compact design due to the high power-to-weight ratio of hydraulic systems. Additionally, hydraulic systems are known for their durability and low maintenance requirements. However, there are disadvantages such as the potential for leaks, which can be hazardous and costly to repair. The systems can also be sensitive to temperature changes, which might affect performance. Lastly, hydraulic fluids can be environmentally harmful if not properly managed, posing disposal challenges.</p>

- Q: This question asks for the steps or process involved in installing a building hoist, which is a type of crane used in construction to lift materials.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the ground is level and strong enough to support the hoist. 2) Assembling the hoist tower, starting from the base and working upwards. 3) Installing the motor and drive system. 4) Attaching the cable and counterweight. 5) Rigging the hoist with safety devices and load limiters. 6) Conducting a thorough inspection and testing the hoist for safety and functionality. 7) Obtaining any necessary permits and approvals. It's crucial to follow the manufacturer's instructions and local regulations, and often requires a professional team for safe and proper installation.</p>

- Q: Where is the location of the elevator in the project

- The position of construction elevator is usually set in the project to facilitate access to material, material handling and personnel up and down, not affecting the construction process.

- Q: Is it possible to store lifting equipment in a residential setting such as a home or garage?

- <p>Yes, you can store your lifting equipment in your home or garage, but there are several considerations to keep in mind. Ensure that the space is dry, well-ventilated, and free from extreme temperatures to prevent rust or damage. Store equipment on stable, level surfaces to prevent tipping. Keep equipment away from children and pets for safety. Regularly inspect equipment for wear and tear, and store it properly when not in use to maintain its condition. Always follow the manufacturer's guidelines for storage to ensure the longevity and safety of your equipment.</p>

- Q: Identify the elements that influence the durability and operational lifespan of lifting machinery, specifically focusing on Building Hoists.

- <p>The lifespan of lifting equipment, including Building Hoists, is influenced by several factors: 1) Material Quality: The type and quality of materials used in construction directly affect durability and resistance to wear and tear. 2) Design and Engineering: Proper design ensures optimal performance and reduces stress on components. 3) Frequency of Use: More frequent use can lead to faster wear and tear. 4) Maintenance and Repair: Regular maintenance can extend the lifespan, while neglect can shorten it. 5) Operating Conditions: Environmental factors such as temperature, humidity, and exposure to corrosive substances can impact longevity. 6) Load Capacity: Overloading can cause premature failure. 7) Compliance with Safety Standards: Adhering to safety guidelines can prevent accidents and damage. 8) Technological Advancements: Newer models may have improved features that extend lifespan.</p>

- Q: For example, what records do you want to have a third party monitoring?

- The elevator overhaul formalities; First report to the local special court, after the approval of the major repair, the major repair unit should have a major repair record to leave the record of party a, including the replacement parts or the procedure that changes. Then the local special inspection hospital will be required to check again.

Send your message to us

Building Hoist Single Cage for Material Transporting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords