Building Hoist SC100 Machines Lifting Material

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist SC100 Machines Lifting Material

The base frame is welded with profile steel and steel board, with four sides connected with enclosure and center as the base for the mast. The base frame can bear all the force of the P/M hoist in vertical direction. During installation, the base frame will be fixed to the concrete foundation by long J-bolts.

The enclosure is welded with angle steel, steel board and steel net, securing the surrounding of the hoist main part to prevent entry when the hoist is in operation. The fence door of the enclosure entrance part is equipped with the mechanical & electrical interlock to protect the labor and machine.

The mast is the force-bearing part of the hoist, also serves as the guiding rail for the cage running. Each mast section is connected with 8.8-level high strength bolts to make up the required height. The mast section, which has superior quality and significant bearing ability, is produced with quality Q235Φ76 seamless steel pipe.

The rack is the major force-bearing part mounted on the mast section, whose material has the same quality with the train wheels, after being tempered and long-time carburized, making it wear-resistant, high-ductile and long life-span.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

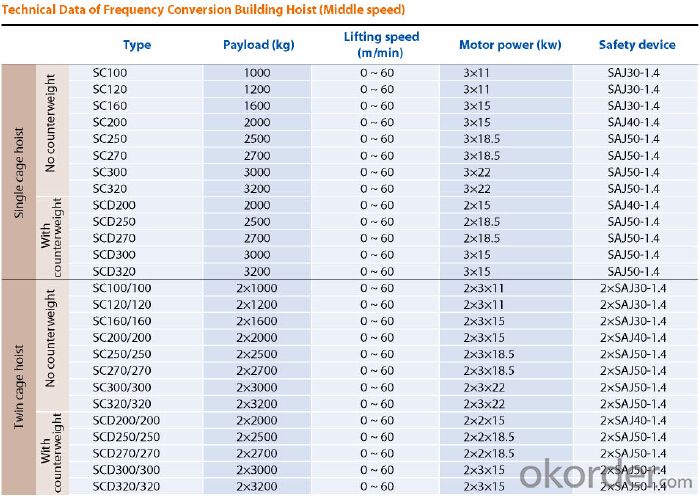

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for guidance on the upkeep and repair procedures for a building hoist, a mechanical device used for lifting materials in construction.

- <p>To maintain and repair a building hoist, follow these steps: Ensure regular inspections by qualified personnel, checking for wear and tear, and addressing any issues promptly. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prolong component life. Replace worn-out cables, pulleys, and other critical components to prevent accidents. Keep the hoist clean and free from debris to prevent jams and malfunctions. For repairs, always consult the manufacturer's manual or hire professional technicians to avoid safety hazards. Regular maintenance and prompt repair are crucial for the safe operation of building hoists.</p>

- Q: This question asks about the process of installing a new building hoist, which is a piece of equipment used in construction to lift materials and personnel.

- <p>Installing a new building hoist involves several steps: 1) Site preparation, ensuring the area is clear and level. 2) Unpacking and inspecting the hoist components for any damage. 3) Assembling the hoist tower, starting with the base and working upwards. 4) Installing the drive unit and cable system. 5) Attaching the counterweight and safety devices. 6) Rigging the hoist to the building structure for stability. 7) Conducting a thorough inspection and testing the hoist for safety and functionality. 8) Obtaining any necessary permits and approvals. 9) Training operators on the safe use of the hoist. It's crucial to follow the manufacturer's instructions and local regulations when installing a building hoist.</p>

- Q: Is it possible to utilize a building hoist for the purpose of moving materials up and down in a warehouse setting?

- <p>Yes, a building hoist can be used to lift and lower materials in warehouses. These hoists are designed for vertical transportation of goods and are particularly useful in multi-story warehouses where space is limited. They are capable of handling heavy loads and can be operated manually or with electric power, making them efficient for moving materials between different levels of a warehouse. However, safety measures and proper maintenance are crucial to ensure the secure and effective operation of the hoist.</p>

- Q: What are the necessary conditions and safety measures to be met when using a building hoist to lift heavy objects?

- <p>Lifting heavy objects with a building hoist requires adherence to several key requirements for safety and efficiency. These include ensuring the hoist is properly installed and inspected, the load is secured correctly, and the weight does not exceed the hoist's capacity. Operators must be trained and certified, and they should follow all safety protocols. The area around the hoist should be clear of obstructions and bystanders. Regular maintenance and checks are crucial to prevent accidents. Additionally, weather conditions, such as high winds, can affect the safety of hoist operations and may require postponing lifts until conditions improve.</p>

- Q: This question asks for the method to determine the maximum weight an electric-hydraulic lifting system can handle.

- <p>To calculate the maximum load capacity of an electric-hydraulic lifting system, you need to consider several factors: the hydraulic cylinder's piston area, the pressure rating of the hydraulic system, and the mechanical strength of the system components. The formula to calculate the maximum load (P) is P = A * P, where A is the area of the piston in square inches or square meters, and P is the pressure in pounds per square inch (psi) or Pascals (Pa). Ensure to convert units if necessary. Additionally, account for safety factors and the mechanical limits of the system to determine the practical maximum load that the system can safely lift without risk of failure.</p>

- Q: A building hoist is a piece of equipment used in construction to lift materials and personnel.

- <p>A building hoist, also known as a construction hoist or material hoist, is a temporary lifting device used in the construction industry to transport materials, equipment, and sometimes personnel vertically within a building under construction. It is essential for efficient movement of heavy and bulky items, reducing manual labor and improving safety by minimizing the need for workers to climb ladders or handle heavy loads manually. These hoists are typically installed on the exterior of the building and are used throughout the construction process until the building's permanent elevators are installed and operational.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments.

- <p>A building hoist can indeed be used both indoors and outdoors, depending on the specific model and design. Outdoor hoists are typically built to withstand weather conditions and are more robust, while indoor hoists are designed for controlled environments. It's crucial to ensure that the hoist is suitable for the intended environment to maintain safety and functionality. Always follow the manufacturer's guidelines and safety regulations when using a building hoist in any setting.</p>

- Q: Elevator installation approach, need to give the total package (inspect) what data, come a master to answer the detail point

- In ten days: installation company qualification (including business license, qualification certificate, safety production license, organization code certificate and company performance, etc.), installation personnel qualifications (including the principal, special operations personnel, etc.), installation construction scheme (including the construction organization design, safety and civilized construction scheme, construction progress) The installation process: in materials to submit for approval (material inspection report, certificate, etc.), play equipment to submit for approval (mechanical factory qualified certificate, safe use license, etc.) After the construction is completed, the certificate of safety inspection (which needs to be provided by the special security agency)

- Q: What are the necessary steps and checks required to maintain a building hoist to ensure its safe and efficient operation?

- <p>Building hoists require regular maintenance to ensure safety and efficiency. This includes daily inspections of the hoist's mechanical and electrical components for any signs of wear or damage. Monthly, a thorough inspection should be conducted by a qualified technician, including checking the hoist's cables, brakes, and safety devices. Lubrication of moving parts and replacement of worn components are also crucial. Annually, a comprehensive inspection and certification by a professional is necessary to comply with safety regulations. Adherence to the manufacturer's guidelines is essential, and any malfunctions should be addressed immediately to prevent accidents.</p>

- Q: Is it possible to utilize building hoists for the transportation of materials and equipment within construction sites?

- <p>Yes, building hoists are commonly used in construction sites to move materials and equipment. They are designed to lift and lower heavy loads vertically, making them ideal for transporting construction materials, tools, and equipment between different floors or levels of a building under construction. This equipment significantly enhances efficiency and safety on construction sites by reducing manual labor and the risk of accidents associated with manual handling of heavy items.</p>

Send your message to us

Building Hoist SC100 Machines Lifting Material

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords