Sheet Glass 1.5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

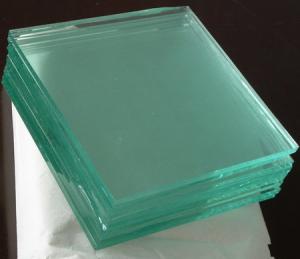

Sheet Glass is a kind of ultra thin glass, whose thickness is less than 3mm.

Features:

1. good planeness

2. little tolerance on thickness

3. excellent quality

Specifications:

Thickness: 1.5mm

Size:

500*700mm; 600*900mm

610*914mm; 1220*914mm

1830*1220mm; 1830*2440mm

customized size

Applications:

Sheet Glass is mainly used in picture frames, mirrors, windows, building, arts and crafts, instruments, etc.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: What is the raw material of glass made of?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history. The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass.

- Q: What is the glass DV board made of?.

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: What is glass fiber reinforced nylon?

- GFR-nylon adds a certain amount of nylon resin in glass fiber reinforced plastic (FR-PA) and can be divided into long glass fiber reinforced nylon coating prepared (fiber and plastic particles equal, generally about 10mm) and the short cut fiber after mixing, or continuous fiber guide short glass fiber into double screw extruder continuous shear mixing of reinforced nylon (glass fiber length of about 0.0.7mm. 2.) belongs to the nylon polyamide amine in its main chain. Amino is polar, due to the effects of hydrogen bonding and attract each other. So the nylon easy to crystallize, can be made into high strength fibers. Polyamide as translucent cuticle toughness or white crystalline resin, often made of cylindrical pellets for polyamide plastic with molecular weight ranging from 15 thousand to 20 thousand.

- Q: What are the raw materials made of glass and plastics?

- Polyethylene (Polyethylene, PE), referred to as PE. is ethylene organic polymer compound. Polyethylene is the best material in contact with food. Non-toxic, tasteless and odorless, conform to the hygiene standards of food packaging. Polyethylene film, transparent, with moisture, oxygen, anti acid and alkali resistance, air tightness in general, excellent heat sealing properties. Known as "plastic flowers" reputation. Plastic packaging and printing volume is the largest and most important materials.PVC-- PVC

- Q: Tempered and reinforced glass

- Tempered glass is a safety glass. It is very small and won't cause serious damage when broken. Toughened glass does not belong to safety glass. Large pieces of debris can cause serious damage.

- Q: Can ordinary white glass (Bai Jiuping) replace quartz glass?

- Quartz glass is a kind of special industrial technology glass made of silicon dioxide. It is a very good basic material.

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- Glass fiber board, also known as glass fiber board, commonly used in soft base cloth, leather bag, outside, a beautiful wall and ceiling decoration. Very wide range of applications. It has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection and flame retardance.FR-4 also known as the glass fiber; glass fiber board; FR4 reinforcing plate; FR-4 epoxy resin board; flame retardant insulation board; epoxy plate, FR4 plate; glass board; PCB drilling pad.

- Q: Why is the process of glass toughened always broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: Failure reasons and solutions of insulating glass.

- To keep the sealant unchanged for a long time, it must require the sealant has good anti-aging properties, if the material quality is not good, it will affect the life of hollow glass products, in all sealants, most can reflect is butyl rubber as the basic raw materials of various types of sealant sealant and moisture barrier properties, and so on standard hollow glass curtain wall curtain wall must adopt double sealing is a very correct decision. Here are a variety of sealants water vapor permeability coefficient table, from the table we can see that the structure of glue can not be used as insulating glass sealant alone.

We are the first special float glass factory in china while one of the world three borosilicate glass manufacturers.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2009 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Sheet Glass 1.5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches