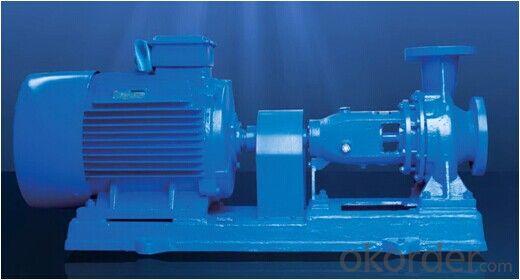

Self-Priming Horizontal Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

ZX series self-priming centrifugal pump falls into the category of self-priming centrifugal pump,which has such advantages as compact structure, easy operation, stable running, easy maintenance, high efficiency, long life and strong self-priming capacity. The bottom valve needn't be mounte in the pipeline. It 's only necessary to reserve a fixed quantity of guide liquid in the pump body before work. Therefore, it simplifies the pipeline system and also improves the labor conditions

2. Range of Application:

1) It is applicable for city environmental protection, building, fire control,chemical engeering,pharmacy,dyestuff,printing and dyeing, brewage, electricity, electroplating, paper making ,petroleum, mine, equipment cooling, tanker discharging,etc.

2) It is applicable for clear water, seawater, liquid containing acid or alkali chemical medium, and generally pasty slurry (medium viscosity≤100cP and solid content less than 30%).

3) When it's mouted with an arm sprayer, it can jet the water into the air to disperse into little raindrops for spraying , so it is a good tool for farm, nursery, orchar and tea garden.

4) It can work with any types and specifications of filter press, so it is an ideal type to deliver the slurry to the filter for the filter pressing.

3. Type Designation:

50 ZX 12.5-50 PB

50 Suction inlet diameter(mm)

ZX Self-priming pump

12.5 Rated flow (m3/h)

50 Lift head (m)

P Stainless steel

B Explosion-proof

4. Technology Parameters:

Flow3-280m3/h

Head12-80m

Power1.5-90kw

Ratary speed14502900r/min

32-200mm

Medium Temperature≤80

Self-priming high3.5-4.5m.

5. FAQ

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice

- Q: The function of centrifugal pump

- 6. Stuffing box mainly consists of packing, water seal ring, stuffing box, packing gland and water seal pipe. The function of the stuffing box is mainly to close the gap between the pump shell and the pump shaft. The water in the pump is not allowed to flow outside and the outside air is not allowed to enter the pump. Always keep the vacuum in the pump! When the pump shaft and packing friction heat, it is necessary to rely on water seal to control water into the water ring, so that the filler cooling! Keep the pump running properly. Therefore, in the water pump running inspection process, the stuffing box inspection is to pay special attention to! In the operation of about 600 hours, it is necessary to replace the packing.

- Q: What should I pay attention to when buying a pump?

- Four, packing inspection1. with the pump supply documents shall include: product certification, specification, packing list, agricultural pumps (such as submersible pumps, centrifugal pumps, mixed flow pumps, self-priming pump etc.) should be "Three Guarantees certificate", the implementation of the production permit (such as pump submersible pump, high pressure pump, high temperature pump 5 pump) we should have a production license.2. plugging of the orifice, to withstand wind and rain invasion, and should be strong, can withstand accidental damage.3. pumps and all supplied bulk parts supplied with the pump shall have the required identification number and shall be clear.4. pairs of oil lubricated bearings, bearings tank oil should be discharged, and fixed with "need oil filling" warning signs.

- Q: Water pump can not be pumped out, how to maintain water?

- Packing overheating:Due to packing too tight, the cooling water can not enter the filler, or the shaft surface damage. Measures for proper relaxation of packing and cleaning of sealing pipe are adopted. Filler wear must be replaced with new ones. Before installation, soak in the oil and rotate it in turn. The incision should be staggered so that water leakage can be reduced. Fill the last lap after installed loading pressed to cover operation for further adjustment of the tightness.

- Q: Fire control center manually start the fire pump directly, multi line control, called straight up line NHKVV-7*1.5, my understanding is: straight line from fire control center

- The vertical line NHKVV-7*1.5 is the remote starting line of fire controller to fire pump room.

- Q: How to install, operate and maintain the pipeline booster pump?

- When the pump leaks, check it immediately to prevent leakage. If it leaks with the motor connection, replace the mechanical seal. Check that the power is connected. Is the supply voltage consistent with the operating voltage of the pump?. If the above a and B are normal, please remove the pump, open the pump cover, remove the foreign body in the pump, and then pump the lid on, and then tighten it to normal.No water pump, pump installed in the tap water pipeline, such as tap water level in the pump impeller on the plane (horizontal installation) or center line (vertical) below, you should turn off the power supply, to tap water level rise more than the impeller plane or the center line, connected to the power supply, to avoid mechanical damage (automatic no need to turn off the electric type). When the pump used in pumping wells, please check whether the water inlet pipe leak; pump cavity storage is not enough, should be filled with water, whether the suction process is too high, proper adjustment. Check whether the inlet and outlet diameter is too small or blocked. Automatic type after a period of time, there may be automatic failure phenomenon, mainly stainless steel and other metal products in pipes, long-term precipitation to shut off the power supply after unloading, unscrew the top screw, remove the plastic sheet to be cleaned, and then, according to the original reset, the normal debugging, can be re used.

- Q: What are the starting and stopping procedures for centrifugal pumps?

- Operation method and operation procedure of self-priming centrifugal pumpClick number: 440 release time: 2011-7-24Centrifugal pump method, centrifugal pump operation steps, centrifugal pump use steps

- Q: What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- Directly said vane pump on the line, generally do not say rotary vane pump.The centrifugal pump is divided according to the direction of the liquid flow in the impeller

- Q: What should be used to pay attention to the use of mechanical pumps?

- There are many kinds of pumps, such as centrifugal pumps, piston pumps, diaphragm pumps, vane pumps, gear pumps, etc.

- Q: How accurate is the metering pump?

- In addition, when the oil supply is too large or the pipeline pressure rises unexpectedly, the volume of the liquid in the hydraulic chamber can be changed, thereby affecting the stability of the flow and reducing the metering accuracy of the pump. In order to solve the problem of how to stabilize the measurement accuracy of metering pump metering pump flow, how stable, the three valve device. The so-called actual refers to the combination of three functions including compensation, discharge and safety protection device or device supporting the hydraulic chamber, according to its action principle is different, is divided into automatic compensation and forced compensation two three valve device.

- Q: What's the submersible pump?What is a submersible pump, and what about it?

- Deep well submersible pump is a fountain, drinking water transportation, irrigation, hot springs, high-rise transport facilities, etc., deep well submersible pump excellent performance, so widely used in various fields.

Send your message to us

Self-Priming Horizontal Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords