Schedule 40 Seamless Carbon Steel Pipe 13CrMo45 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

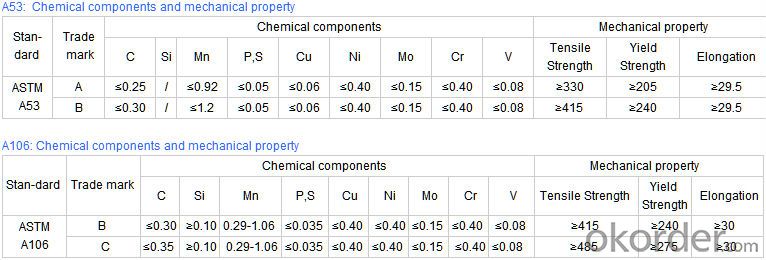

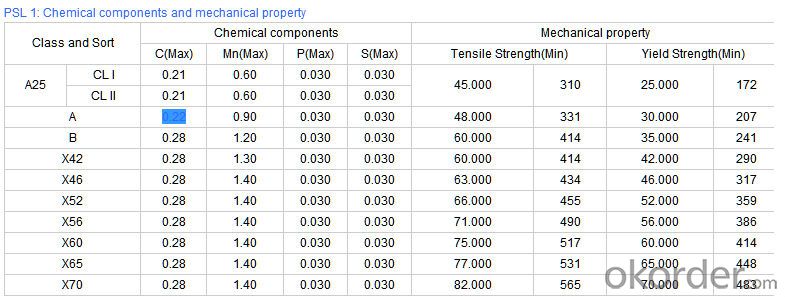

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: What does seamless steel tube mean? What are the main uses? What are the classifications?

- Electrical, gas, water, power, fluid, pipe.The main production process for hot rolling seamless steel tube (the main inspection):Tube preparation and check delta to billet heating, heating, rolling, perforated pipe, steel pipe and heat treatment, diameter (minus) Delta to finished tube straightening, finishing and inspection of delta (nondestructive, physicochemical, Taiwan inspection and warehousing)Main production process of cold rolled (drawn) seamless steel tube:Blank preparation, pickling, lubrication, cold rolling (drawing), heat treatment, straightening, finishing and inspection

- Q: What is the role of steel pipes in the telecommunications industry?

- Steel pipes play a crucial role in the telecommunications industry as they are used for the installation of underground and overhead telecommunication cables. These pipes provide protection and support to the cables, ensuring their safety and longevity. Additionally, steel pipes are also used in the construction of communication towers and infrastructure, making them an essential component in establishing and maintaining reliable telecommunications networks.

- Q: Can steel pipes be used for conveying steam?

- Indeed, steam can be conveyed using steel pipes. Steel pipes find frequent application in steam distribution systems owing to their impressive strength and long-lasting nature. They possess the ability to endure high temperatures and pressures associated with steam transportation without succumbing to deformation or leakage. Furthermore, steel pipes exhibit remarkable heat resistance properties, rendering them suitable for conveying steam at elevated temperatures. Nevertheless, it is crucial to guarantee adequate insulation of the steel pipes in order to avert heat loss and uphold the desired steam temperature throughout the transportation process.

- Q: Can steel pipes be used for underground culverts?

- Yes, steel pipes can be used for underground culverts. Steel pipes are known for their strength, durability, and resistance to various environmental factors, which makes them suitable for underground applications. They can withstand heavy loads, high water pressure, and the corrosive effects of soil and water. Additionally, steel pipes are available in various sizes and thicknesses, allowing for customization to fit specific project requirements. However, it is important to consider factors such as the soil conditions, water table levels, and potential for corrosion when selecting the appropriate type of steel and protective coatings for the pipes.

- Q: Can steel pipes be used for sewage treatment plants?

- Yes, steel pipes can be used for sewage treatment plants. Steel pipes are durable and resistant to corrosion, making them ideal for handling sewage and wastewater in such facilities. They are commonly used for conveying and distributing sewage, as well as for constructing various components like pipelines, pump stations, and treatment tanks. Additionally, steel pipes can withstand high pressure and are available in various sizes, making them suitable for the diverse needs of sewage treatment plants.

- Q: What are the factors that affect the lifespan of steel pipes in different environments?

- The factors that affect the lifespan of steel pipes in different environments include exposure to corrosive substances, temperature fluctuations, water quality, and mechanical stress.

- Q: How are steel pipes protected against external mechanical damage?

- Steel pipes are protected against external mechanical damage through various methods. One common method is the use of protective coatings. These coatings provide a physical barrier between the steel surface and external forces, such as impact or abrasion. Coatings can be applied through processes like painting, epoxy coating, or wrapping the pipe with materials like polyethylene or polypropylene. Another method of protection is the use of external casing or encasement. Casing pipes are installed around the steel pipes to provide an additional layer of protection. These casing pipes are typically made of materials like concrete, PVC, or ductile iron, which are resistant to external mechanical damage. Furthermore, steel pipes can be protected by using supports and restraints. Properly designed supports and restraints help to distribute external forces evenly and prevent excessive stress or deformation on the pipe. This includes using hangers, clamps, or brackets to secure the pipe in place and minimize the risk of mechanical damage. In addition, steel pipes can be protected by implementing measures to prevent accidental impacts or collisions. This can involve installing protective barriers, fencing, or warning signs to alert people to the presence of pipelines and prevent unintentional damage. Overall, a combination of protective coatings, casing, supports, and preventive measures is utilized to ensure that steel pipes are safeguarded against external mechanical damage. These measures help to maintain the structural integrity of the pipes and ensure their long-term performance and reliability.

- Q: What are the common sizes of steel pipe fittings?

- Depending on the particular application and industry regulations, the sizes of steel pipe fittings can vary. Nevertheless, there are numerous standard sizes that are commonly utilized in various industries. These sizes encompass a range from ¼ inch to 48 inches in diameter. Among the most frequently used sizes are ½ inch, ¾ inch, 1 inch, 1 ¼ inch, 1 ½ inch, 2 inch, 2 ½ inch, 3 inch, 4 inch, 6 inch, 8 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, 30 inch, 36 inch, 42 inch, and 48 inch. These sizes are often obtainable in different lengths to accommodate diverse installation requirements. To determine the appropriate size of steel pipe fittings for a specific project, it is crucial to refer to industry standards and specifications.

- Q: Where is a steel pipe casing usually used?

- Classification of casing: rigid casing, flexible waterproof sleeve, steel pipe sleeve and iron sheet bushing, etc..

- Q: Are steel pipes suitable for underground irrigation systems?

- Yes, steel pipes are suitable for underground irrigation systems. They are durable, resistant to corrosion, and can withstand high pressure, making them a reliable choice for transporting water underground.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 13CrMo45 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords