Schedule 40 Seamless Carbon Steel Pipe 15CrMo CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

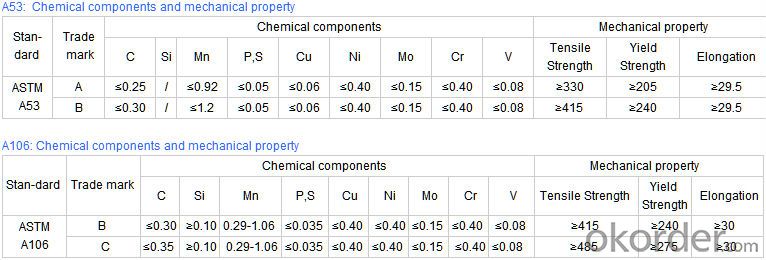

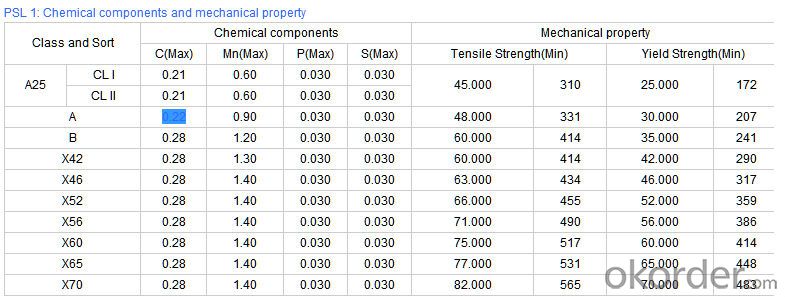

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: How are steel pipes threaded for easy installation?

- The process of threading steel pipes enables convenient installation by creating grooves or ridges in the pipe, forming a spiral pattern that facilitates connection with other threaded components like fittings or valves. There are two commonly employed methods for threading steel pipes: manual threading and machine threading. Manual threading involves the utilization of a handheld tool called a pipe die. This die, equipped with sharp teeth, cuts into the pipe while it is rotated. The pipe is secured in a vise or held firmly by hand, and the die is applied to the pipe's end. As the die rotates around the pipe, threaded grooves are formed. Executing this process necessitates skill and precision to ensure accurate and properly aligned threads. In contrast, machine threading is a more automated procedure. It utilizes a pipe threading machine, which possesses a die head that automatically cuts the threads into the pipe. The machine holds the pipe securely and rotates it while the die head moves along the pipe's length, creating the threads. Machine threading is faster and more efficient than manual threading, making it ideal for large-scale production or projects. Regardless of the chosen method, it is imperative to ensure that the threads are clean and devoid of debris or burrs. This is crucial for effortless installation and to prevent leaks or other complications. Following threading, the pipes are generally inspected to ensure compliance with the required specifications. Threading steel pipes allows for uncomplicated installation as the threaded ends can be readily screwed into fittings, valves, or other pipes possessing compatible threads. This threaded connection creates a tight seal, rendering it suitable for various applications such as plumbing, gas lines, or industrial piping systems.

- Q: How are steel pipes used in the construction of offshore platforms?

- Steel pipes are extensively used in the construction of offshore platforms due to their durability, strength, and corrosion resistance. These pipes form the structural framework of the platform, providing support and stability. They are utilized for various purposes such as transporting fluids, including oil and gas, and for the installation of risers, which connect the platform to subsea equipment. Additionally, steel pipes are employed in the construction of pipelines and flowlines, facilitating the transportation of hydrocarbons from the platform to onshore facilities.

- Q: What's the difference between round and round tubes?

- Round steel is generally refers to steel, the surface is not threaded, different from round steel pipe, round tube is round tube.

- Q: Can steel pipes be used for underground applications?

- Yes, steel pipes can be used for underground applications. They are commonly used for underground piping systems in various industries such as water, oil, and gas. The durability and strength of steel make it suitable for withstanding underground conditions, providing reliable and long-lasting performance.

- Q: What connections are there for concrete filled steel tubular column foundations?

- The Liang Duan local widening joint is achieved by the continuous construction of longitudinal steel bars around the steel tube. At the beginning of the creation of additional stirrups should be widened longitudinal reinforced wrap, Liang Duan local widened joints of steel reinforced concrete beam and corbel overlapping transition zone can transmits beam internal force, bending steel bracket in both shear and participation. The node form is used in building engineering in Xiamen. The force transfer path of this joint is clear and reliable, with less welding on site and more convenient for construction. This kind of node passes shear stress through the bracket, and the stress is more concentrated.

- Q: How are steel pipes measured and sized?

- Steel pipes are measured and sized based on their diameter and wall thickness. The standard unit for measuring steel pipes is the nominal pipe size (NPS), which is a North American set of standard sizes for pipes. The NPS is based on the internal diameter (ID) of the pipe, while the wall thickness is specified by the schedule number. The schedule number indicates the thickness of the pipe walls, with higher numbers representing thicker walls. Additionally, steel pipes can also be measured and sized using outside diameter (OD) and wall thickness in millimeters or inches.

- Q: How long are the seamless tubes? Are they six meters long?

- The production process of seamless steel tube in general can be divided into two kinds of hot rolling and cold drawing, cold-rolled seamless steel pipe production process than hot-rolled seamless steel pipe seamless pipe hot rolling to complex, diameter is generally greater than 32mm, thickness 2.5-200mm, cold-rolled seamless steel pipe outside diameter 6mm, wall thickness to 0.25mm cold rolling hot rolling high precision ratio.

- Q: How are steel pipes connected or joined together?

- Steel pipes are typically connected or joined together using various methods such as welding, threading, flanges, or couplings.

- Q: Can steel pipes be used for underground air supply systems?

- Yes, steel pipes can be used for underground air supply systems. Steel pipes are commonly used for underground applications due to their durability, strength, and resistance to corrosion. They can effectively transport compressed air, making them suitable for underground air supply systems.

- Q: How are steel pipes connected in pipeline construction?

- Steel pipes are connected in pipeline construction through various methods, including welding, threading, and flanges. Welding involves joining the pipes by melting the edges and fusing them together, creating a strong and continuous connection. Threading involves screwing the pipes together using threaded ends, ensuring a secure connection. Flanges are used to connect pipes with the help of bolts, providing a detachable yet sturdy connection. These methods ensure the integrity and safety of the pipeline system.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 15CrMo CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords