Schedule 40 Seamless Carbon Steel Pipe 13CRMO44 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

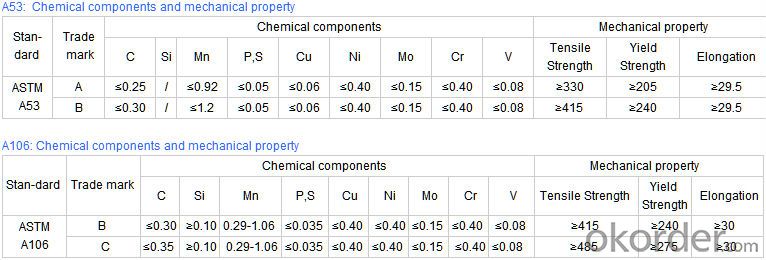

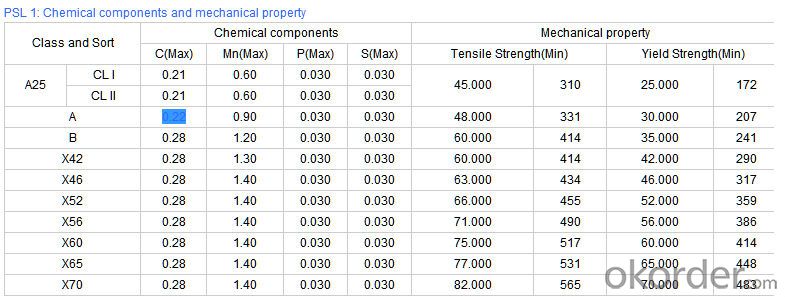

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: When can I use the PVC pipe and when to use the galvanized pipe?

- PVC pipeline use temperature is -5 to 90 degrees or so, according to the current market price of around 6000 yuan per ton, the price is cheap. Its corrosion resistance is good, can resist most of the acid and alkali, and unlike the steel pipe that is easy to rust, so in the construction of the upper and lower water pipes and other fields have gradually replaced the trend of steel pipe.

- Q: How do steel pipes handle extreme temperatures?

- Steel pipes can handle extreme temperatures due to their high strength and thermal stability. The properties of steel, such as its excellent heat resistance and low thermal expansion, allow it to withstand both high and low temperatures without significant deformation or structural damage. Additionally, the use of specialized coatings and insulation can further enhance the heat resistance of steel pipes, making them suitable for a wide range of applications in extreme temperature environments.

- Q: How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into three categories: schedule, standard, and extra strong.

- Q: How are steel pipes used in the manufacturing of bicycles?

- Steel pipes are used in the manufacturing of bicycles as they provide a strong and durable framework for the bicycle's structure. These pipes are typically used to construct the frame, handlebars, and seat post, ensuring stability and support for the rider. Additionally, steel pipes allow for customization and flexibility in design, allowing manufacturers to create various types and styles of bicycles to suit different riding needs.

- Q: Can steel pipes be used for underground fuel pipelines?

- Indeed, underground fuel pipelines can utilize steel pipes for their construction. Steel pipes are widely favored for different pipeline applications owing to their exceptional durability, strength, and resistance to corrosion. In the case of underground fuel pipelines, steel pipes are particularly sought-after due to their capacity to endure significant pressure and fluctuations in temperature. Moreover, by shielding against external factors like soil shifts and chemical reactions, steel pipes offer exceptional safeguarding to the fuel transportation system, ensuring its safety and integrity. Through appropriate insulation and coating, the corrosion resistance of steel pipes can be further enhanced, solidifying their dependability as a choice for underground fuel pipelines.

- Q: Stainless steel tube, also known as why tube?

- Production methods can be divided into two categories: seamless pipe and welded pipeSeamless steel pipe can be divided into hot-rolled pipe, cold rolled tube, cold drawn tube and extruded tubeWelded pipe is divided into straight welded pipe and spiral welded pipe and so on

- Q: How do steel pipes differ from other types of pipes?

- Steel pipes differ from other types of pipes in several ways. Firstly, steel pipes are incredibly durable and strong, making them suitable for carrying high-pressure fluids and gases. They have a high resistance to corrosion and can withstand extreme temperatures, making them ideal for various industrial applications. Additionally, steel pipes have a smooth interior surface, which reduces friction and allows for efficient flow of liquids or gases. They are also highly versatile, as they can be easily welded, threaded, or bent to fit specific project requirements. Overall, steel pipes are known for their strength, durability, and versatility, making them a preferred choice in many industries.

- Q: What are the different types of joints used in steel pipes?

- The different types of joints used in steel pipes include butt weld, socket weld, threaded, and flanged joints.

- Q: Can steel pipes be used for underground chemical injection?

- Yes, steel pipes can be used for underground chemical injection. Steel pipes are known for their durability and corrosion resistance, making them suitable for various applications, including underground chemical injection. However, it is also important to consider the type of chemical being injected and verify if steel pipes are compatible with the specific chemical to avoid any potential reactions or degradation.

- Q: How are steel pipes made?

- Steel pipes are made through a process called pipe manufacturing, which involves multiple steps. Firstly, raw steel is melted in a furnace and then subjected to continuous casting to form a solid billet. This billet is then heated and pierced to create a hollow tube called a shell. Next, the shell is rolled and stretched to the desired diameter and thickness using a series of rollers. The pipe is then subjected to a process called welding, where two edges of the shell are fused together to create a seamless or welded pipe. Finally, the pipe undergoes various finishing processes such as cutting, straightening, and inspection before being ready for use.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe 13CRMO44 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords