Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Screw Jack Formwork Scaffolding China Low Price

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

Scaffolding Screw Jack Formwork Scaffolding China Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

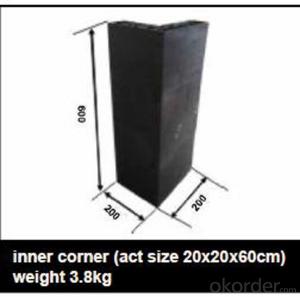

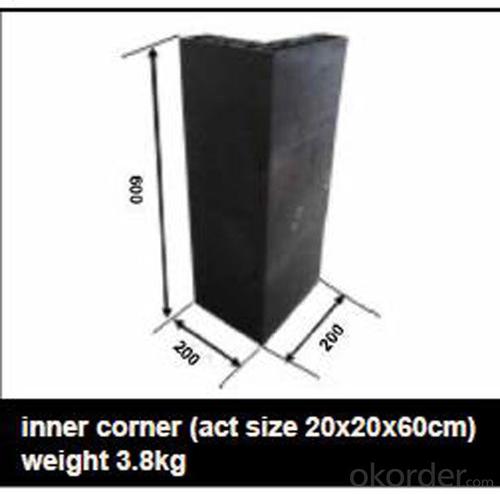

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Q: Does steel frame formwork require any specific reinforcement detailing?

- Specific reinforcement detailing is necessary for steel frame formwork. Steel frame formwork is a construction system used to create concrete structures. It consists of steel frames, typically made of steel beams and columns, that support plywood panels or other formwork materials. The steel frames themselves must be designed and reinforced to withstand the loads of the concrete and the pressure during pouring and curing. This involves determining the size and spacing of the steel beams and columns, as well as the reinforcement detailing within them. To enhance the strength and durability of steel frame formwork, additional steel bars or mesh are typically added to the beams and columns. This reinforcement prevents bending, buckling, and failure under the weight and pressure of the concrete. The specific reinforcement requirements depend on factors such as the size and height of the structure, anticipated loads, and local building codes. In addition to reinforcing the steel frame, reinforcement detailing may also be needed for the concrete itself. Steel rebars are placed and spaced within the concrete to provide additional strength and structural integrity. The specific reinforcement requirements for the concrete depend on design requirements, structural calculations, and the intended use and load-bearing capacity of the structure. In conclusion, steel frame formwork requires specific reinforcement detailing to ensure the structural integrity and safety of the formwork system and the resulting concrete structure. Professional engineers and designers play a crucial role in determining the appropriate reinforcement detailing, considering the project's specific requirements and conditions.

- Q: How does steel frame formwork handle the pouring and curing of concrete in extreme temperatures?

- Steel frame formwork is a popular choice in construction due to its durability and ability to handle extreme temperatures during the pouring and curing of concrete. The steel frame provides a strong and stable structure that can withstand the pressure exerted by the concrete during pouring. Additionally, the steel material has a high melting point, which makes it resistant to deformation or damage caused by extreme heat. In extreme cold temperatures, steel frame formwork offers several advantages. Firstly, the steel material has a low thermal expansion coefficient, meaning it does not contract significantly when exposed to cold temperatures. This characteristic ensures that the formwork remains stable and does not warp or crack during the concrete pouring and curing process. Furthermore, steel frame formwork can be easily insulated to prevent freezing of the concrete mix in extremely cold climates. Insulating materials such as foam boards or blankets can be attached to the steel frame, providing a barrier between the concrete and the cold environment. This insulation helps to maintain the necessary temperature for proper curing of the concrete, preventing any potential damage or deterioration. In extreme hot temperatures, steel frame formwork also proves to be advantageous. The steel material has a high thermal conductivity, meaning it can efficiently dissipate heat and prevent excessive temperature build-up. This characteristic helps to regulate the temperature of the concrete during the curing process, preventing the formation of cracks or other thermal-related issues. Additionally, steel frame formwork can be easily coated with reflective materials or painted in lighter colors to minimize heat absorption. This further aids in maintaining suitable curing temperatures, even in scorching conditions. Overall, steel frame formwork is designed to handle extreme temperatures during the pouring and curing of concrete. Its robustness, low thermal expansion coefficient, insulation capabilities, and heat dissipation properties make it a reliable choice for construction projects in a wide range of climates.

- Q: What are the different types of formwork braces used in steel frame formwork systems?

- Steel frame formwork systems commonly utilize various types of formwork braces to provide stability and support during the pouring and curing of concrete. These braces play a crucial role in ensuring the integrity of the formwork. Here are several different types of formwork braces commonly used: 1. Adjustable Steel Braces: Made of steel, these braces offer adjustable length and are primarily utilized for horizontal support in the formwork system. Their adjustable feature enables flexibility in adapting to different formwork heights. 2. Push-Pull Props: Also known as shore props or acrow props, these telescopic tubular supports are employed to provide vertical support in the formwork. They can be easily adjusted to the desired height and are often used in conjunction with adjustable steel braces. 3. Strut Braces: Comprising steel tubes connected diagonally to the formwork system, strut braces deliver diagonal support and hinder lateral movement of the formwork. They prove particularly valuable in situations involving high wind loads or when additional support is required. 4. Cross Braces: Steel bars are utilized as cross braces to connect vertical formwork elements. They contribute to the lateral stability of the formwork system and help maintain the desired form and shape throughout the concrete pouring process. 5. Corner Braces: Designed specifically to support the corners of the formwork system, corner braces ensure stability and squareness during the concrete pouring and curing process. 6. Tension Rods: Tension rods reinforce the overall strength of the formwork system by providing additional support and stability. They are commonly used in conjunction with other braces, such as adjustable steel braces or strut braces. These represent some of the various types of formwork braces employed in steel frame formwork systems. The selection and combination of braces depend on factors including formwork size, complexity, load requirements, and environmental conditions at the construction site.

- Q: How does steel frame formwork help in reducing construction time?

- By providing a faster and more efficient method of constructing concrete structures, steel frame formwork plays a crucial role in reducing construction time. Firstly, its lightweight and easy-to-handle nature allows for quicker assembly and disassembly compared to traditional formwork systems. This enables the formwork to be easily relocated and reused in different areas of the construction site, saving valuable time. Additionally, steel frame formwork is highly versatile and adaptable, allowing for the construction of complex structures in various shapes, sizes, and configurations. It can be easily adjusted and modified to accommodate changes in design or construction requirements, minimizing the time spent on alterations and adjustments. Furthermore, the use of steel frame formwork ensures a high level of accuracy and precision. The rigid steel frames guarantee consistent dimensions and alignment, resulting in accurate and uniform concrete structures. This eliminates the need for extensive rework and corrections, saving valuable time during the construction process. Moreover, steel frame formwork contributes to faster curing times for concrete. Acting as a heat sink, the steel frames dissipate heat from the concrete, accelerating the curing process. This allows for the faster removal of formwork, facilitating the progression of construction activities. Lastly, steel frame formwork boasts a longer lifespan and can be reused multiple times, reducing the need for frequent replacements. This not only saves construction time but also reduces costs associated with purchasing and disposing of formwork materials. In conclusion, steel frame formwork offers several advantages that significantly reduce construction time. Its ease of handling, versatility, accuracy, faster curing times, and reusability make it the preferred choice for contractors aiming to enhance the efficiency and speed of their construction projects.

- Q: Can steel frame formwork be used for curved or irregular shaped structures?

- Yes, steel frame formwork can be used for curved or irregular shaped structures. Its flexibility and strength allow for the creation of customized formwork that can be easily adjusted to match the desired shape of the structure. This makes steel frame formwork a suitable choice for challenging architectural designs that require curved or irregular shapes.

- Q: What are the safety measures that need to be taken while using steel frame formwork?

- Some of the safety measures that need to be taken while using steel frame formwork include wearing appropriate personal protective equipment (PPE) such as safety helmets, gloves, and safety boots. It is important to ensure that the formwork is inspected regularly for any defects or damage before use. Workers should receive proper training on the correct assembly and dismantling procedures to prevent accidents. Adequate bracing and support should be provided to ensure stability and prevent collapse. Additionally, following proper handling techniques and using appropriate lifting equipment can help prevent injuries.

- Q: How does steel frame formwork affect the overall insulation of a structure?

- Steel frame formwork does not directly affect the overall insulation of a structure. The insulation of a building is primarily determined by the materials used for the walls, roofs, and floors, as well as the installation techniques employed. Steel frame formwork, on the other hand, is a temporary structure used during the construction process to mold and shape concrete. It provides a strong and sturdy support system for the concrete until it cures and gains its strength. While steel frame formwork itself may not have a direct impact on insulation, it can indirectly affect it in a few ways. Firstly, the presence of steel frame formwork may require additional insulation measures to be taken, especially in colder climates, to prevent heat loss during the construction phase. This could include the use of temporary insulation materials or heating systems to maintain a suitable temperature for the curing process. Secondly, the installation of steel frame formwork may involve penetrations or voids in the concrete structure, which could potentially compromise the insulation if not addressed properly. These penetrations or voids can create thermal bridges that allow heat to escape or enter the structure, reducing its overall energy efficiency. Therefore, it is important to carefully seal and insulate any openings or gaps created during the formwork installation to maintain an effective insulation barrier. In summary, steel frame formwork does not directly affect the overall insulation of a structure. However, it can indirectly influence insulation requirements and may contribute to thermal bridging if not properly addressed. It is crucial to consider insulation strategies and take appropriate measures during the construction phase to ensure an energy-efficient and well-insulated building.

- Q: How does steel frame formwork affect the overall durability of a concrete structure in harsh environments?

- In harsh environments, the use of steel frame formwork can greatly improve the overall durability of a concrete structure. By utilizing steel as the formwork material, several advantages are gained that help mitigate the negative effects of challenging conditions. To begin with, steel is renowned for its exceptional strength and durability. It has the ability to withstand heavy loads and extreme weather conditions, rendering it highly resistant to damage. This strength enables the steel frame formwork to support the weight of the wet concrete during the pouring and curing process, ensuring proper alignment and preventing any deformation or collapse of the structure. Additionally, steel possesses corrosion resistance, which is of particular concern in harsh environments like coastal areas or places with high humidity. Serving as a protective barrier, the steel frame formwork shields the concrete from exposure to moisture, saltwater, chemicals, and other corrosive elements. This safeguards the concrete from deteriorating over time, guaranteeing its long-term durability. Moreover, steel frame formwork provides outstanding dimensional stability. It reduces the risk of warping, cracking, or other deformations that can arise due to temperature variations, moisture content, or shrinkage of the concrete. This stability contributes to the structural integrity of the concrete, ensuring that it maintains its strength and functionality over an extended period. Furthermore, steel formwork allows for precise and accurate construction. The design of the steel frames ensures a stable and rigid structure, guaranteeing that the concrete is poured and compacted evenly throughout the formwork. As a result, a more uniform and durable concrete structure is achieved, with fewer imperfections or weak points. Ultimately, the application of steel frame formwork significantly enhances the overall durability of a concrete structure in harsh environments. Its strength, corrosion resistance, dimensional stability, and precise construction capabilities all contribute to the long-term structural integrity and functionality of the concrete, making it a reliable choice for projects in challenging conditions.

- Q: What are the different types of connections used in steel frame formwork?

- Steel frame formwork employs various types of connections, each serving a distinct purpose and offering different benefits. 1. Wedge connections: These connections involve using steel wedges to secure formwork panels. The wedges are inserted into pre-drilled panel holes and hammered in to create a tight and secure connection. Wedge connections are swift and effortless to assemble and disassemble, making them perfect for projects with repetitive formwork needs. 2. Clamp connections: In this type of connection, steel clamps hold the formwork panels together by gripping their edges. Clamp connections provide strong and stable connections, offering excellent strength and stability. Therefore, they are suitable for complex and heavy-duty formwork applications. 3. Pin connections: Pin connections employ steel pins to join formwork panels. The pins are inserted into pre-drilled holes and secured with nuts or other fasteners. Pin connections provide good strength and stability and are commonly used in formwork systems that require frequent adjustments or reconfigurations. 4. Bolted connections: Bolted connections utilize steel bolts and nuts to connect formwork panels. Panels are drilled with holes, and bolts are inserted through these holes and tightened with nuts. Bolted connections offer high strength and rigidity, making them appropriate for large-scale formwork systems and projects with heavy loads. 5. Magnetic connections: Magnetic connections are a recently developed type of connection in steel frame formwork. These connections use powerful magnets embedded in formwork panels to attract and hold the panels together. Magnetic connections offer quick and easy assembly and disassembly, as well as high flexibility and adaptability in formwork design. Each connection type has its own advantages and suitability for specific formwork applications. The choice of connection depends on factors such as project requirements, formwork design, load capacity, ease of assembly, and time constraints.

- Q: How does steel frame formwork facilitate the construction process?

- The construction process is facilitated in several ways by steel frame formwork. To begin with, it possesses exceptional durability, enabling it to withstand the pressure and weight of concrete during pouring and curing. As a result, construction can proceed at a faster pace since there is no frequent need for replacement or repair of the formwork. Furthermore, steel frame formwork is highly adaptable and can be easily adjusted and customized to fit structures of different shapes and sizes. This flexibility allows for efficient construction of various types of buildings, including those with complex and unique designs. In addition, steel frame formwork is lightweight when compared to traditional materials like timber or plywood. Consequently, it is easier to handle and transport, thereby reducing labor and construction time. Moreover, steel frame formwork can be assembled and disassembled with ease, enabling quick installation and removal on construction sites. This not only saves time during the construction process but also ensures faster project completion. Furthermore, steel frame formwork ensures a smooth and level surface finish, minimizing the need for additional plastering or finishing work. This streamlines the construction process and enhances the overall quality of the finished structure. Overall, the utilization of steel frame formwork in construction offers advantages such as durability, adaptability, lightweightness, ease of assembly, and a smooth surface finish. These benefits contribute to faster construction, cost savings, and improved efficiency within the construction industry.

Send your message to us

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords