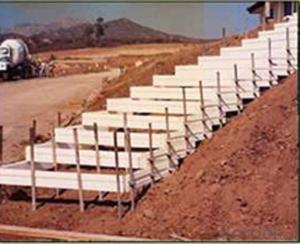

Scaffolding For Painters Formwork Scaffolding Bs1139 For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

- Q: Can steel frame formwork be used for both reinforced and non-reinforced concrete structures?

- Yes, steel frame formwork can be used for both reinforced and non-reinforced concrete structures. Steel frame formwork is a versatile system that can be easily adjusted and adapted to meet the requirements of various construction projects. It provides a strong and rigid framework for pouring concrete, ensuring the stability and integrity of the structure. Whether there is reinforcement or not, the steel frame formwork can be designed and installed to provide the necessary support and shape for the concrete during the construction process. It is commonly used in the construction industry for a wide range of projects, including buildings, bridges, tunnels, and other concrete structures, regardless of whether they are reinforced or non-reinforced.

- Q: European steel bed frame and rubber high density board that good

- Because of the two different species, there is not much comparability

- Q: How is the quality of the concrete surface achieved with steel frame formwork?

- The use of steel frame formwork results in a high-quality concrete surface for several reasons. Firstly, the rigid and stable structure of steel frame formwork ensures that the fresh concrete is evenly poured and compacted, preventing any irregularities or deformations. Additionally, the design of steel frame formwork includes adjustable elements like clamps, tie rods, and spacers, which allow for precise alignment and leveling. This guarantees that the concrete is poured at the correct thickness and with consistent dimensions, resulting in a smooth and uniform surface. Furthermore, steel frame formwork often incorporates form liners or surface treatments that can create decorative patterns or textures on the concrete. These liners or treatments can be easily attached to the steel frames, enabling the creation of aesthetically pleasing finishes. Moreover, the durability and reusability of steel frame formwork are advantageous, especially in large construction projects. The ability to reuse the same formwork multiple times without compromising the quality of the concrete surface ensures uniformity throughout the project. In conclusion, the use of steel frame formwork ensures a high-quality concrete surface due to its stability, adjustability, and durability. These factors contribute to the creation of a smooth, even, and aesthetically pleasing surface that meets all required standards and specifications.

- Q: What are the environmental benefits of using steel frame formwork?

- Using steel frame formwork offers several environmental benefits. Firstly, steel is a highly durable material, which means that the formwork can be used repeatedly, reducing the need for constant replacement. This reduces the amount of waste generated and minimizes the environmental impact associated with producing new formwork. Additionally, steel is a recyclable material, so at the end of its life cycle, it can be recycled and used for other purposes, further reducing waste. Furthermore, steel frame formwork allows for precise and efficient construction, resulting in less material wastage and energy consumption during the construction process. Overall, the use of steel frame formwork helps to minimize environmental degradation and promotes sustainable construction practices.

- Q: How does steel frame formwork contribute to the overall quality of a concrete structure?

- Steel frame formwork is a construction technique that utilizes steel frames to support concrete structures as they are poured and cured, resulting in improved overall quality. To begin with, the use of steel frame formwork guarantees exceptional stability and rigidity, ensuring even and precise pouring of the concrete. The frames are designed to be robust and sturdy, minimizing any potential movement or deformation during the pouring process. This stability is vital in maintaining the structural integrity of the concrete, preventing the formation of cracks or inconsistencies. Furthermore, steel frame formwork allows for precise shaping and alignment of the concrete structure. The frames can be easily adjusted and aligned to accommodate any desired shape or design, ensuring that the final structure meets exact specifications and requirements. This precision is crucial in achieving a high-quality finish and an aesthetically pleasing appearance. Moreover, steel frame formwork facilitates efficient construction processes. The frames are lightweight and easy to handle, enabling quick assembly and disassembly. This speed and ease of use enhance the overall productivity of the construction project, resulting in faster completion times and reduced labor costs. Additionally, the reuse of steel formwork frames makes them a cost-effective solution for multiple projects, further enhancing their economic value. Additionally, steel frame formwork offers exceptional durability and longevity. The frames are constructed from high-quality steel, which is resistant to corrosion, weathering, and wear. This durability ensures that the formwork can withstand the pressures and forces exerted during the pouring and curing process, maintaining its structural integrity over time. As a result, structures built using steel frame formwork have increased longevity and require minimal maintenance or repairs. In conclusion, the utilization of steel frame formwork significantly improves the overall quality of concrete structures. Its stability, precision, efficiency, and durability all play a crucial role in ensuring accurate pouring, precise shaping, and long-lasting integrity. By incorporating steel frame formwork, construction projects can achieve high-quality, visually appealing, and durable concrete structures.

- Q: Can steel frame formwork be used for both straight and inclined concrete elements?

- Certainly! Both straight and inclined concrete elements can be constructed using steel frame formwork. This versatile formwork can be effortlessly adjusted and assembled to fit different shapes and angles. It offers stability and durability, ensuring the concrete's weight is adequately supported during pouring and curing. The steel frame can be tailored to create straight walls, columns, beams, slabs, and even inclined or curved structures. Additionally, this formwork system facilitates simple removal and reusability, making it a cost-efficient choice for construction projects that involve both straight and inclined concrete elements.

- Q: How does steel frame formwork ensure proper anchoring to the ground?

- Steel frame formwork ensures proper anchoring to the ground through several key features and techniques. Firstly, steel frame formwork is designed with sturdy steel frames that provide excellent stability and strength. These frames are securely anchored to the ground using a variety of methods such as steel stakes, ground anchors, or bolts. Additionally, steel frame formwork often includes adjustable legs or leveling screws, which allow for precise positioning and alignment on uneven ground surfaces. These adjustable elements ensure that the formwork is securely grounded and properly leveled, which is essential for achieving accurate and high-quality construction results. Moreover, steel frame formwork can also incorporate additional anchoring devices such as tie rods or braces, which further enhance its stability and resistance to external forces. These anchoring devices are strategically placed and secured to the ground, ensuring that the formwork remains firmly in place during the pouring and curing of concrete. Furthermore, steel frame formwork is often designed with integrated locking mechanisms or connection systems that provide a secure and rigid connection between individual formwork panels. This interlocking feature enhances the overall stability of the formwork system and prevents any lateral movement or displacement during the construction process. Overall, steel frame formwork is specifically engineered to ensure proper anchoring to the ground by combining robust steel frames, adjustable leveling mechanisms, anchoring devices, and interlocking systems. These features work in unison to provide a stable, secure, and reliable formwork system that can withstand the forces exerted during concrete pouring and curing, ultimately resulting in a structurally sound and well-built construction project.

- Q: What are the different types of access systems used with steel frame formwork?

- There are several different types of access systems that can be used with steel frame formwork, depending on the specific requirements of the construction project. One commonly used access system is the ladder system. This involves attaching ladders to the steel frame formwork, which allows workers to easily climb up and down the formwork structure. Ladder systems are typically used for smaller structures or when access is only needed at certain points along the formwork. Another type of access system is the stair tower system. This involves constructing a separate tower structure alongside the steel frame formwork, which contains stairs or a ladder system. Stair tower systems are more commonly used for larger structures or when access is required at multiple levels of the formwork. In some cases, a platform system may be used as an access system with steel frame formwork. This involves constructing a platform structure that is attached to the steel frame formwork, providing a stable and secure platform for workers to access the formwork. Platform systems are often used when there is a need for extended access or when multiple workers need to access the formwork at the same time. Additionally, a crane or hoist system may be used as an access system with steel frame formwork. This involves using a crane or hoist to lift workers and materials up to the formwork structure. Crane or hoist systems are typically used when there is limited space for traditional access systems or when heavy materials need to be lifted onto the formwork. Overall, the choice of access system for steel frame formwork will depend on factors such as the size and complexity of the structure, the level of access required, and the specific needs of the construction project.

- Q: How does steel frame formwork handle different concrete mix designs?

- Steel frame formwork is a versatile and resilient system that can easily handle different concrete mix designs. The strength and durability of steel make it capable of withstanding the pressure and weight exerted by various types of concrete mixes. One of the key advantages of steel frame formwork is its adjustable nature. The formwork can be easily customized or modified to suit the specific requirements of different concrete mix designs. This flexibility allows for the construction of structures with varying shapes, sizes, and load-bearing capacities. Furthermore, steel frame formwork provides excellent support and stability to the concrete during the pouring and curing process. It effectively contains the concrete mix and prevents any leakage or deformation. The rigid steel structure ensures that the formwork remains intact, even when subjected to the high pressure exerted by certain concrete mixes. In addition, steel frame formwork is highly resistant to corrosion, which is especially beneficial when dealing with concrete mixes that contain aggressive chemicals or additives. The steel frame is protected from the corrosive effects of the concrete, ensuring its long-term durability and performance. Overall, steel frame formwork is specifically designed to handle different concrete mix designs with ease. Its adjustability, strength, stability, and corrosion resistance make it a reliable choice for contractors and builders looking to construct structures using various types of concrete mixes.

Send your message to us

Scaffolding For Painters Formwork Scaffolding Bs1139 For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches