SBS Membrane Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SBS Membrane Smooth for Waterproof System

Description Of SBS Membrane Smooth for Waterproof System:

1. TPO Membrane Smooth is made from Thermoplastic polyethylene hydrocarbons , which is for waterproofing of exposed and non-exposed applications.

2. TPO Membrane Smooth adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. TPO Membrane Smooth is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of SBS Membrane Smooth for Waterproof System:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of SBS Membrane Smooth for Waterproof System:

Material | SBS modified asphalt impregnated and coated tire base |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Smooth |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of SBS Membrane Smooth for Waterproof System:

1.Roofs, Basement

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

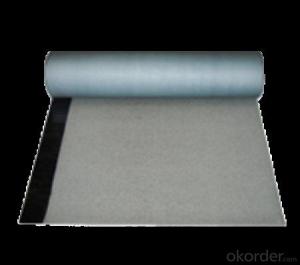

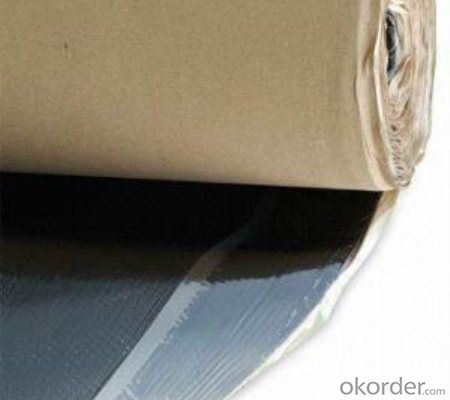

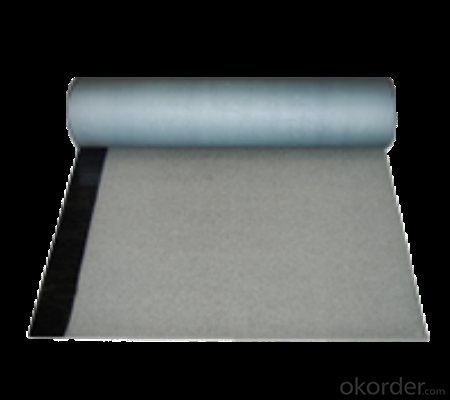

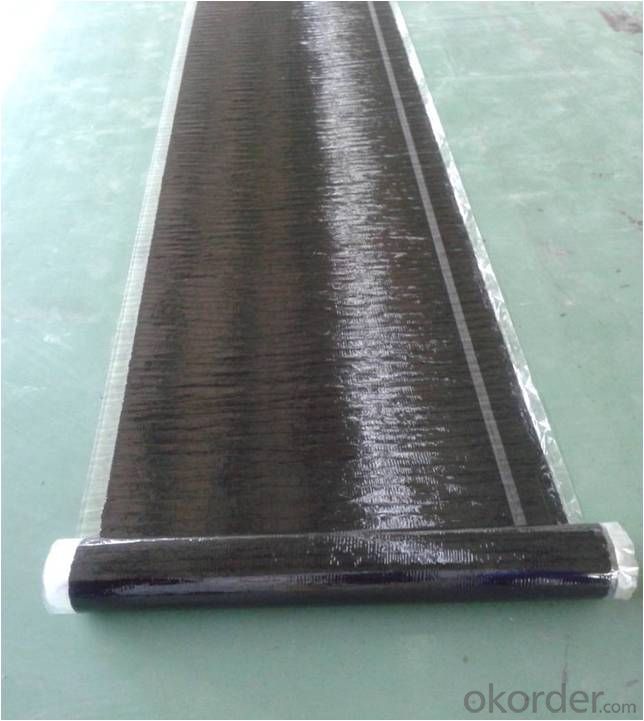

IMages of TPO Membrane Smooth for Waterproof System:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can a waterproofing membrane be pre-fabricated or pre-made for easy installation?

- Yes, a waterproofing membrane can be pre-fabricated or pre-made for easy installation. Pre-fabricated membranes are manufactured in controlled environments, allowing for consistent quality and performance. They are designed to be installed quickly and easily, reducing labor time and cost. Pre-made membranes also ensure a precise fit and minimize the risk of installation errors. Overall, pre-fabricated or pre-made waterproofing membranes offer convenience and efficiency in the installation process.

- Q: Can a waterproofing membrane be used on precast steel surfaces?

- Yes, a waterproofing membrane can be used on precast steel surfaces. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they can be applied to a variety of surfaces, including precast steel. The membrane acts as a waterproof layer, preventing water from penetrating the surface and causing damage. It is important to ensure that the surface is properly prepared and cleaned before applying the membrane to ensure proper adhesion and effectiveness. Additionally, it is recommended to consult with a professional waterproofing contractor to determine the best type of membrane and application method for the specific precast steel surface.

- Q: Can a waterproofing membrane be used for a bridge deck?

- Yes, a waterproofing membrane can be used for a bridge deck. In fact, it is a common practice to apply a waterproofing membrane to bridge decks to protect the structure from moisture ingress, which can lead to corrosion and deterioration. A waterproofing membrane acts as a barrier to prevent water from seeping into the concrete deck, ensuring the longevity and durability of the bridge. Furthermore, it can also help to reduce the potential for freeze-thaw damage, which is especially important in areas with harsh weather conditions. Overall, using a waterproofing membrane for a bridge deck is a reliable solution to enhance its lifespan and maintain its structural integrity.

- Q: Can a waterproofing membrane be used on swimming pools?

- Yes, a waterproofing membrane can be used on swimming pools. Waterproofing membranes are commonly used in the construction and maintenance of swimming pools to prevent water leakage and seepage. These membranes act as a barrier, ensuring that the pool remains watertight and preventing any water damage to the surrounding structures.

- Q: Can waterproofing membranes be used on metal surfaces?

- Yes, waterproofing membranes can be used on metal surfaces. Waterproofing membranes are designed to create a barrier that prevents water from penetrating surfaces, regardless of the material. Metal surfaces can be prone to corrosion and water damage, so applying a waterproofing membrane can help protect them from moisture and extend their lifespan. The type of waterproofing membrane used may vary depending on the specific needs and requirements of the metal surface, but there are various options available specifically designed for metal applications. These membranes are typically flexible, durable, and resistant to UV rays and other environmental factors, ensuring long-lasting protection for the metal surfaces.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: Can waterproofing membranes be used on outdoor decks?

- Yes, waterproofing membranes can be used on outdoor decks. Waterproofing membranes are a popular choice for outdoor decks as they provide an effective barrier against moisture, preventing water from seeping through and causing damage to the underlying structure. These membranes are typically made of durable materials such as rubber or PVC and are designed to withstand exposure to the elements. They are applied directly onto the deck surface, creating a waterproof seal that protects the deck from rain, snow, and other forms of moisture. Additionally, waterproofing membranes can also help to prolong the lifespan of the deck by preventing water damage, rot, and decay. Therefore, using waterproofing membranes on outdoor decks is a practical and effective solution for maintaining the integrity and longevity of the deck.

- Q: Can waterproofing membranes be used on balconies?

- Yes, waterproofing membranes can be used on balconies. These membranes are designed to provide a protective barrier against moisture, preventing water leaks and damage to the balcony structure. Waterproofing membranes are commonly used in balcony construction and renovation projects to ensure long-lasting water resistance and durability.

- Q: Can a waterproofing membrane be used for military facilities?

- Indeed, military facilities can benefit greatly from the utilization of a waterproofing membrane. Designed specifically to create a protective barrier against water infiltration, these membranes play a crucial role in safeguarding structures and equipment from potential harm. In military settings like barracks, hangars, and command centers, the implementation of a waterproofing membrane guarantees the preservation of the building envelope's integrity. This, in turn, shields it from moisture intrusion, mold growth, and potential structural damage. Moreover, the use of a waterproofing membrane further enhances the facility's durability and longevity, ultimately reducing the need for costly repairs and maintenance in the long run. Consequently, the application of a waterproofing membrane offers immense advantages to military facilities, ensuring a resilient and robust infrastructure capable of withstanding diverse environmental conditions.

- Q: Can a waterproofing membrane be used for schools or universities?

- Yes, a waterproofing membrane can definitely be used for schools or universities. Waterproofing membranes are commonly used in various construction projects, including educational institutions, to protect the building from water damage. These membranes are applied to the exterior surfaces of the structure, such as roofs, walls, or foundations, to create a barrier that prevents water infiltration. By implementing a waterproofing membrane, schools and universities can ensure that their buildings remain dry and free from water-related issues such as leaks, mold growth, or structural damage. This not only helps to maintain the integrity and longevity of the building but also provides a safe and comfortable environment for students, staff, and visitors. Additionally, waterproofing membranes can also be used in areas such as bathrooms or wet laboratories to prevent water seepage, which is especially important in educational settings where high traffic and frequent use of water are common. Overall, using a waterproofing membrane in schools or universities is a proactive measure to protect the infrastructure, enhance durability, and promote a conducive learning environment.

Send your message to us

SBS Membrane Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords