PVC Membrane Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Membrane Smooth for Waterproof System

Description Of PVC Membrane Smooth for Waterproof System:

1. PVC Membrane Smooth is made from PVC and poliester , which is for waterproofing of exposed and non-exposed applications.

2. PVC Membrane Smooth adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. PVC Membrane Smooth is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of PVC Membrane Smooth for Waterproof System:

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

4. High puncture resistance

5. High aging resistance

6. UV resistance

Specifications of PVC Membrane Smooth for Waterproof System:

Material | PVC |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Smooth |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of PVC Membrane Smooth for Waterproof System:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

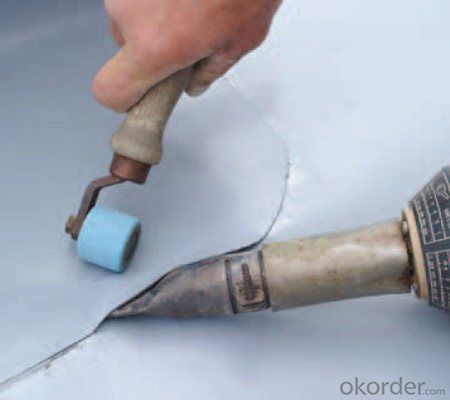

IMages of PVC Membrane Smooth for Waterproof System:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Does a waterproofing membrane provide any insulation against temperature fluctuations?

- No, a waterproofing membrane does not provide any insulation against temperature fluctuations. Its primary function is to prevent water infiltration and protect the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used on chrome surfaces?

- While a waterproofing membrane can potentially be applied to chrome surfaces, it may not be essential or advisable. Chrome surfaces usually possess natural resistance to water and moisture thanks to their inherent properties and protective coatings. These coatings effectively shield against corrosion and prevent water-related harm. Consequently, adding an extra layer of waterproofing membrane onto a chrome surface might not yield any additional advantages and could potentially compromise the chrome's appearance and functionality. To ensure the appropriate treatment for chrome surfaces, it is always wise to consult the manufacturer or seek guidance from a professional in the field.

- Q: Can a waterproofing membrane be used for a shopping mall?

- Yes, a waterproofing membrane can be used for a shopping mall. A shopping mall typically has multiple levels and a large surface area, which makes it susceptible to water infiltration from rain, plumbing leaks, or other sources. Installing a waterproofing membrane can provide an effective solution to protect the structure and its contents from water damage. The membrane is typically applied to the exterior walls, roofs, and foundation of the shopping mall to create a barrier against moisture penetration. It acts as a protective layer that prevents water from seeping into the building, reducing the risk of structural damage, mold growth, and other related issues. Additionally, a properly installed waterproofing membrane can also help to improve energy efficiency by reducing heat loss and preventing water-related deterioration of insulation materials. Therefore, using a waterproofing membrane is a wise choice for ensuring the long-term durability and functionality of a shopping mall.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Yes, a waterproofing membrane can be used for tunnels or subway systems. Tunnels and subway systems are often subjected to water infiltration due to the surrounding soil conditions or groundwater levels. To prevent water from entering these underground structures, a waterproofing membrane is commonly applied. This membrane acts as a barrier, preventing water from seeping into the tunnels or subway systems. It is typically installed on the exterior surface of the tunnel walls and roof, creating a watertight seal. This helps to prevent corrosion, decay, and damage to the structural elements of the tunnels and ensures the safety and longevity of these underground infrastructures.

- Q: Are waterproofing membranes resistant to mineral oils?

- Yes, waterproofing membranes are generally resistant to mineral oils.

- Q: Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Waterproofing membranes are typically able to resist gasoline and other substances that are petroleum-based. These membranes are commonly manufactured from materials like polyurethane or PVC, which are recognized for their ability to withstand chemicals and petroleum products. This resistance guarantees that the membrane remains intact and effective at preventing water from infiltrating even when it is exposed to gasoline or other petroleum-based substances. However, it is crucial to mention that the actual level of resistance may vary depending on the type and quality of the waterproofing membrane being used. It is recommended to seek advice from a professional or review the product specifications to ensure that the selected membrane is suitable for the intended application involving gasoline or petroleum-based substances.

- Q: Can a waterproofing membrane be installed by a DIYer?

- Installing a waterproofing membrane can be done by someone who wants to do it themselves. However, it is important to keep in mind that the installation process can be complicated and requires careful attention to detail. It is crucial to thoroughly understand the instructions and guidelines provided by the manufacturer before attempting the installation. In addition, it is essential to properly prepare the surface in order to have a successful installation. This may involve cleaning, leveling, and priming the surface to ensure that the membrane adheres correctly. It is also important to choose the appropriate type and thickness of membrane for the specific application. Moreover, DIYers should have the necessary tools and equipment, like a trowel or roller, to apply the membrane accurately. Depending on the specific membrane and installation method, specialized tools may also be required in some cases. Considering safety measures is also important. It is recommended to wear protective gear and work in a well-ventilated area. Some waterproofing membranes may involve the use of hazardous chemicals, so it is crucial to follow all safety instructions provided by the manufacturer. If you are uncertain about your ability to properly install a waterproofing membrane, it is advisable to seek advice from a professional contractor who specializes in waterproofing. They have the knowledge and expertise to ensure a correct installation that will effectively protect your property from water damage.

- Q: Can a waterproofing membrane be used in parking garages?

- Yes, a waterproofing membrane can be used in parking garages. It is commonly used to protect the structure from water damage, such as leaks and corrosion, which can be caused by water infiltrating through the concrete. A waterproofing membrane helps to create a barrier that prevents water penetration, ensuring the durability and longevity of the parking garage.

- Q: Can a waterproofing membrane be used for plant rooms?

- Indeed, plant rooms can benefit from the utilization of a waterproofing membrane. These rooms frequently accommodate machinery and equipment that necessitate safeguarding against water and moisture. Employing a waterproofing membrane can effectively avert water-related harm to both the plant room and its enclosed equipment. By establishing a protective barrier, the membrane effectively prohibits the infiltration of water into the walls, floors, and ceilings of the plant room. This becomes particularly crucial in regions prone to water leaks or condensation. Waterproofing membranes are meticulously engineered to endure diverse environmental circumstances, guaranteeing enduring protection for plant rooms.

- Q: What is waterproofing membrane?

- Waterproof membrane requirements have good water resistance, stability of the temperature change (high temperature does not flow, no blistering, not confuse; low temperature does not brittle crack), a certain mechanical strength, extensibility and resistance to fracture, to There is a certain degree of flexibility and anti-aging and so on. The waterproofing membrane is a curlable sheet-like waterproofing material. Is one of the important varieties of waterproofing materials in construction engineering.

Send your message to us

PVC Membrane Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords