SBS Membrane Smooth and Non- Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SBS Membrane Smooth and Non- Smooth for Waterproof System

Description Of SBS Membrane Smooth and Non- Smooth for Waterproof System

1. SBS Membrane Smooth is made from Thermoplastic polyethylene hydrocarbons , which is for waterproofing of exposed and non-exposed applications.

2. SBS Membrane Smooth adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

3. SBS Membrane Smooth is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of SSBS Membrane Smooth and Non- Smooth for Waterproof System

1. Excellent physical and mechanical performance

2. High tearing resistance

3. Good deformation adaptability

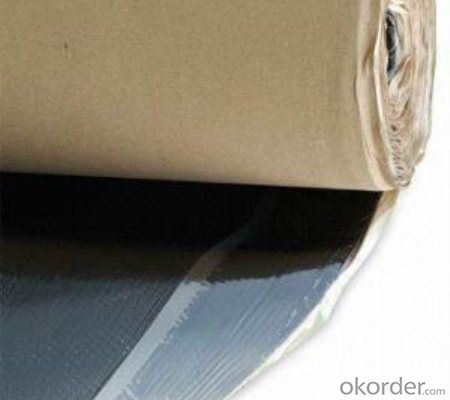

Material | SBS modified asphalt impregnated and coated tire base |

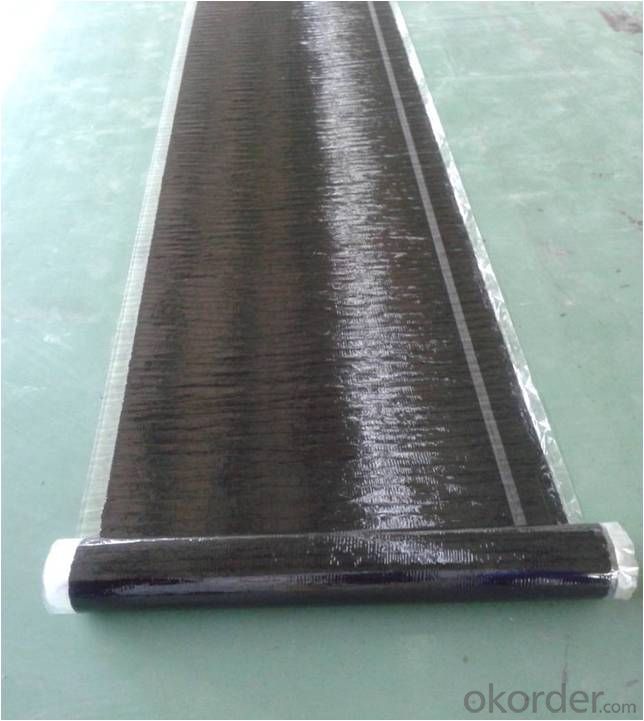

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m |

Thick | 1.2mm, 1.5mm, |

Type | Smooth and Non- Smooth |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of SBS Membrane Smooth and Non- Smooth for Waterproof System

1.Roofs, Basement

2. Industrial and civil building waterproofing

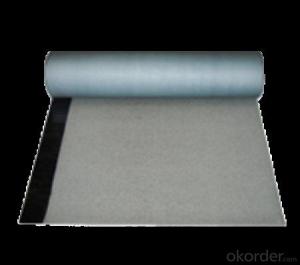

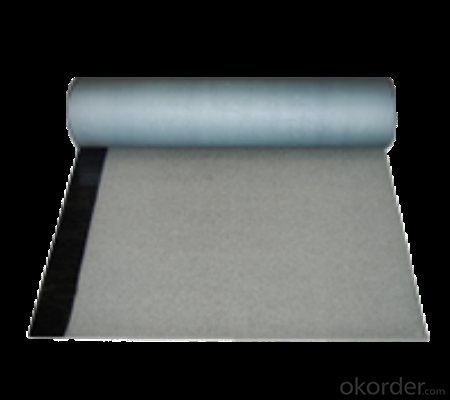

IMages of SBS Membrane Smooth and Non- Smooth for Waterproof System

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 12 years.

3. How long do we usually reply your request?

We always reply our customer within 4 hours.

- Q: Are waterproofing membranes resistant to sulfuric acid exposure?

- Waterproofing membranes are generally not resistant to sulfuric acid exposure. Sulfuric acid is a highly corrosive substance that can cause severe damage to many materials, including waterproofing membranes. Due to the strong acidic nature of sulfuric acid, it can react with and degrade the membrane, leading to its failure. Therefore, if there is a possibility of sulfuric acid exposure, it is important to use acid-resistant materials specifically designed to withstand such corrosive substances.

- Q: Can waterproofing membranes be used on retaining walls?

- Yes, waterproofing membranes can be used on retaining walls. These membranes are designed to prevent water penetration and can help protect the retaining wall from moisture damage.

- Q: How does a waterproofing membrane compare to other waterproofing methods?

- A waterproofing membrane is a highly effective and reliable method of waterproofing compared to other traditional waterproofing methods. Here are some ways in which a waterproofing membrane stands out: 1. Superior Protection: A waterproofing membrane provides a continuous and seamless barrier against water intrusion. Unlike other methods like waterproof paints or coatings, which may crack or peel over time, a membrane can withstand extreme weather conditions and prevent water from seeping through. 2. Longevity: Waterproofing membranes are designed to be durable and long-lasting. They are usually made from materials such as rubber, PVC, or modified bitumen, which have excellent resistance to wear and tear. As a result, they can provide a reliable waterproofing solution for many years. 3. Versatility: Waterproofing membranes can be applied to various surfaces, including concrete, metal, and wood. They can be used in a wide range of applications such as roofs, basements, foundations, and even tunnels. This versatility makes them suitable for both residential and commercial projects. 4. Flexibility: Waterproofing membranes are flexible, allowing them to conform to the shape and contours of the surface they are applied to. This flexibility ensures that the membrane can accommodate any movements or shifts in the structure, preventing any potential cracks or gaps that could lead to water leakage. 5. Ease of Installation: Installing a waterproofing membrane is usually straightforward and can be done by professionals or experienced DIYers. The membrane is typically rolled out onto the surface, adhered with adhesive or heat-welded, and then sealed at the edges and seams. This ease of installation makes it a popular choice for both new construction and retrofit projects. 6. Cost-Effectiveness: While the initial cost of installing a waterproofing membrane may be higher compared to other methods, its long-term cost-effectiveness makes it a wise investment. The durability and longevity of the membrane mean that there will be fewer maintenance and repair costs over time, saving money in the long run. In conclusion, a waterproofing membrane offers superior protection, longevity, versatility, flexibility, ease of installation, and cost-effectiveness compared to other waterproofing methods. Its ability to provide a continuous and reliable barrier against water intrusion makes it a preferred choice for many construction projects.

- Q: Can a waterproofing membrane be used in swimming pools?

- Yes, a waterproofing membrane can be used in swimming pools. In fact, it is a common practice to use waterproofing membranes in the construction or renovation of swimming pools to prevent water leakage. These membranes are specifically designed to create a barrier against water penetration, ensuring that the pool remains watertight and free from leaks. The membranes are typically made from durable materials such as PVC, EPDM, or polyurethane, which are resistant to water, chemicals, and UV rays. Additionally, the membranes are flexible and can easily adapt to the shape and contours of the pool, providing a seamless and long-lasting waterproofing solution.

- Q: Does a waterproofing membrane provide any additional structural reinforcement?

- No, a waterproofing membrane does not provide any additional structural reinforcement. The primary purpose of a waterproofing membrane is to prevent the ingress of water or moisture into a building or structure. It acts as a barrier, typically applied on the exterior surface, to keep water out and protect the underlying materials from damage caused by water. While it can enhance the durability and longevity of a structure by preventing water-related issues such as leakage, dampness, or mold growth, it does not contribute to the structural integrity or strength of the building. Structural reinforcement is typically achieved through the use of materials like steel, concrete, or other load-bearing components, which are designed to carry and distribute the weight and loads of the structure.

- Q: Can a waterproofing membrane be used on aerated concrete block surfaces?

- Indeed, the application of a waterproofing membrane is viable for aerated concrete block surfaces. The permeable nature of aerated concrete blocks renders them susceptible to water infiltration. Employing a waterproofing membrane on the blocks' surface can effectively impede water penetration and avoid harm. The membrane establishes a barrier that obstructs water passage while still enabling the blocks to respire and eliminate any trapped moisture. This facilitates the preservation and longevity of the aerated concrete block structures. However, it is imperative to ensure that the waterproofing membrane selected is explicitly engineered for aerated concrete blocks, as diverse materials necessitate distinct types of membranes for optimal performance.

- Q: Can a waterproofing membrane be used in food processing or pharmaceutical facilities?

- Yes, a waterproofing membrane can be used in food processing or pharmaceutical facilities. Waterproofing membranes are commonly used in these types of facilities to ensure that the surrounding environment remains dry and free from water damage. They create a protective barrier against moisture, preventing leaks and water penetration. This is particularly important in food processing and pharmaceutical facilities where hygiene and cleanliness are crucial. Waterproofing membranes can be applied to various surfaces such as floors, walls, and ceilings, ensuring that all areas are adequately protected. Additionally, these membranes are often made from materials that are resistant to chemicals and bacteria growth, further enhancing their suitability for use in these sensitive environments. Overall, utilizing a waterproofing membrane in food processing or pharmaceutical facilities is an effective way to maintain a dry and safe environment for the production of quality products.

- Q: Roof SBS waterproofing membrane additional layer needs to be wide

- Roof SBS waterproofing membrane additional layer width of 15-20cm, angle attached layer 25cm on each side. Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane.

- Q: Can waterproofing membranes be used on below-grade parking structures?

- Yes, waterproofing membranes can be used on below-grade parking structures. In fact, they are commonly used to protect these structures from water infiltration and potential damage. Waterproofing membranes are designed to provide a barrier against water penetration, thus preventing moisture from seeping into the concrete and causing deterioration. These membranes can be applied to the below-grade walls and floors of parking structures to ensure their long-term durability and structural integrity. Additionally, waterproofing membranes can also help prevent the formation of mold and mildew, which can be a common issue in damp environments such as below-grade parking structures. Overall, using waterproofing membranes is highly recommended for below-grade parking structures to protect them from water damage and extend their lifespan.

- Q: Can a waterproofing membrane be used in stadiums or sports complexes?

- Yes, a waterproofing membrane can certainly be used in stadiums or sports complexes. In fact, it is highly recommended to use waterproofing solutions in these types of structures to protect them from water damage and leakage. A waterproofing membrane acts as a barrier, preventing water from seeping into the concrete or other materials used in the construction of the stadium or sports complex. This is particularly important in areas where heavy rainfall or high humidity is common. By applying a waterproofing membrane to the roofs, walls, and foundations of these structures, it helps to ensure the integrity and longevity of the building, while also providing a comfortable and safe environment for athletes and spectators alike. Waterproofing membranes are designed to withstand the stresses and movements associated with the building, making them an ideal solution for stadiums and sports complexes. Additionally, modern waterproofing membranes are available in various forms, such as liquid-applied or sheet membranes, allowing for flexibility in application and compatibility with different construction materials.

Send your message to us

SBS Membrane Smooth and Non- Smooth for Waterproof System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords