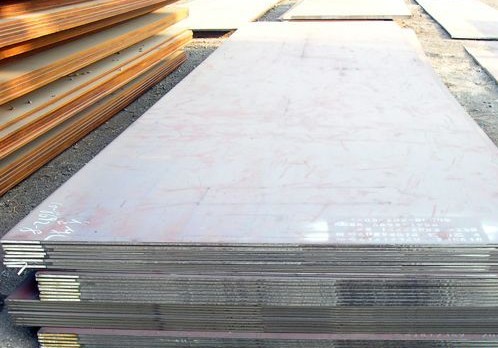

SA299B plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SA299A /SA299B vessel plate

SA299 is divided into two grade A, grade B.SA299A/SA299B is a kind of pressure vessel steel, common in the electric heater, nuclear power project with the container, which belongs to the thick steel plate. SA299A

main following pressure vessel steel plate: B61N-, P690QL1SA302GrC, SA203E/D, 13MnNiMoR, 13MnNiMo5-4,20MnMoR (20MnMo), SA299A/B, (DIWA353\BHW35), SA387MGr11, the corresponding domestic brands of 14Cr1MoR, 12Cr1MoV (R),

Chemical composition of SA299A: carbon (C) content of 0.28-0.30 manganese(Mn) plates less than 25mm melting analysis 0.90-1.40 product analysis of 0.84-1.52 plate is greater than 25mm melting analysis of 0.90-1.50, analysis of finished0.84-1.62 P max 0.035, Max 0.035 of sulfur, silicon smelting analysis of 0.15-0.40product analysis 0.13-0.45.

SA299A /SA299B vessel plate

SA299 is divided into two grade A, grade B.SA299A/SA299B is a kind of pressure vessel steel, common in the electric heater, nuclear power project with the container, which belongs to the thick steel plate. SA299A

main following pressure vessel steel plate: B61N-, P690QL1SA302GrC, SA203E/D, 13MnNiMoR, 13MnNiMo5-4,20MnMoR (20MnMo), SA299A/B, (DIWA353\BHW35), SA387MGr11, the corresponding domestic brands of 14Cr1MoR, 12Cr1MoV (R),

Chemical composition of SA299A: carbon (C) content of 0.28-0.30 manganese(Mn) plates less than 25mm melting analysis 0.90-1.40 product analysis of 0.84-1.52 plate is greater than 25mm melting analysis of 0.90-1.50, analysis of finished0.84-1.62 P max 0.035, Max 0.035 of sulfur, silicon smelting analysis of 0.15-0.40product analysis 0.13-0.45.

- Q: What material can be used for A36 steel plate?

- Q means yield strength, and Q345 indicates the yield strength of this steel is 345MPa. Q345 will decrease the yield value as the thickness of the material increases. And domestic may be small high strength steel plate in 345, so in mechanical design, the strength must be less than 345 this value, otherwise there will be problems.

- Q: Can steel sheets be used for industrial shelving?

- Yes, steel sheets can be used for industrial shelving. Steel sheets are durable, strong, and resistant to corrosion, making them an excellent choice for heavy-duty industrial shelving applications. They provide stability and can withstand heavy loads, making them ideal for storing various industrial products and materials.

- Q: Can the steel sheets withstand extreme temperatures?

- Steel sheets are renowned for their remarkable durability and strength, rendering them ideal for a myriad of applications. Concerning extreme temperatures, steel sheets generally possess an elevated melting point and can endure high temperatures without compromising their structural integrity. Nevertheless, it is worth noting that the precise temperature threshold hinges upon the particular type and grade of steel employed. For instance, stainless steel sheets exhibit superior heat resistance in comparison to carbon steel sheets. Moreover, variables such as the duration of exposure to extreme temperatures and the presence of other environmental factors may also impact the performance of steel sheets. Consequently, it is imperative to take these variables into account, seek guidance from experts, or refer to specific product specifications to ascertain the suitability of a given steel sheet for a specific application involving extreme temperatures.

- Q: What are the most common thicknesses of steel sheets?

- Steel sheets come in various thicknesses, which are determined by their intended use and industry standards. Examples of commonly used thicknesses include 20 gauge (0.035 inches), 18 gauge (0.0478 inches), 16 gauge (0.0598 inches), 14 gauge (0.0747 inches), and 10 gauge (0.1046 inches). These thicknesses are commonly employed in sectors like construction, automotive, and manufacturing. In certain cases, thinner gauges like 24 gauge (0.0239 inches) and 22 gauge (0.0299 inches) may be utilized for lighter applications or when weight reduction is a priority. Ultimately, the chosen thickness will depend on the specific project requirements and the desired structural integrity.

- Q: Can steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding. Steel is a ferromagnetic material, meaning it can easily be magnetized and demagnetized. When placed between a magnetic source and an object, steel sheets can help redirect and absorb the magnetic field, thus providing effective shielding against magnetic interference.

- Q: Can steel sheets be used for manufacturing medical devices?

- Yes, steel sheets can be used for manufacturing medical devices. Steel is often chosen for its durability, strength, and resistance to corrosion, making it suitable for various medical applications such as surgical instruments, implants, and equipment components.

- Q: What are the different coating options for steel sheets (powder coating, paint, etc.)?

- Steel sheets have a variety of coating options that each have their own unique benefits and characteristics. Some commonly used coating options include: 1. Powder coating: Dry powder coating material is applied to the steel sheet and then cured under heat to create a protective layer. This coating offers excellent durability, corrosion resistance, and aesthetic appeal. It is also environmentally friendly as it does not contain solvents or VOCs. 2. Paint: Liquid paint is applied to the surface of the steel sheet and dries to form a protective layer. Paint coatings come in a wide range of colors and finishes, making them suitable for different applications. However, they may require regular maintenance and can chip or peel. 3. Galvanizing: Galvanizing is a popular method for coating steel sheets, particularly when corrosion resistance is important. A layer of zinc is applied to the steel surface through a hot-dip process, creating a protective barrier against corrosion and rust. Galvanized coatings are highly durable and long-lasting. 4. Epoxy coatings: Epoxy coatings are known for their excellent chemical resistance and adhesion properties. They provide a tough and durable finish that protects steel sheets from corrosion, chemicals, and abrasion. Epoxy coatings are commonly used in industrial settings with harsh conditions. 5. Chromate conversion coatings: Chromate conversion coatings are applied to steel sheets to enhance their corrosion resistance and improve paint adhesion. These coatings are usually thin and translucent, giving a clear or slightly yellowish appearance. They are often used as a pre-treatment before painting or powder coating. 6. Ceramic coatings: Ceramic coatings offer exceptional heat resistance and durability. They are commonly used in high-temperature applications such as exhaust systems or industrial ovens. Ceramic coatings can withstand extreme temperatures, corrosion, and abrasion, making them ideal for demanding environments. There are many other coating options available for steel sheets. The choice of coating will depend on factors such as the intended application, desired appearance, environmental conditions, and budget. Seeking advice from a coating specialist or manufacturer can help determine the most suitable option for specific requirements.

- Q: What are the different surface treatments available for steel sheets?

- There are several surface treatments available for steel sheets, including galvanizing, painting, powder coating, and plating.

- Q: How are steel sheets measured and classified?

- Steel sheets are measured and classified based on their thickness, width, and length. The thickness is typically measured in gauge or millimeters, while the width and length are measured in inches or millimeters. They are further classified based on their grade, which indicates the quality and composition of the steel.

- Q: What are the different types of steel sheet finishes?

- There are several different types of steel sheet finishes, including mill finish, brushed finish, mirror finish, galvanized finish, and painted finish.

Send your message to us

SA299B plate steel production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords