Raw Materials for Refractory:Rotaty Kiln Calcined Bauxite Powder with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Powder | Material: | Castable |

| SiO2 Content (%): | 0.5-15 | Al2O3 Content (%): | 55-95 | MgO Content (%): | 0.3 |

| CaO Content (%): | 0.3 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | Customer's Requirement | Brand Name: | cnbm |

Packaging & Delivery

| 1. 25KG or 50KG bag inside, jumbo bag outside or pallet 2. Wooden pallet and then polyethylene film is placed over it, finally the package is tied up with strips. | |

| Delivery Detail: | Within 20 days |

bauxite refractory powder

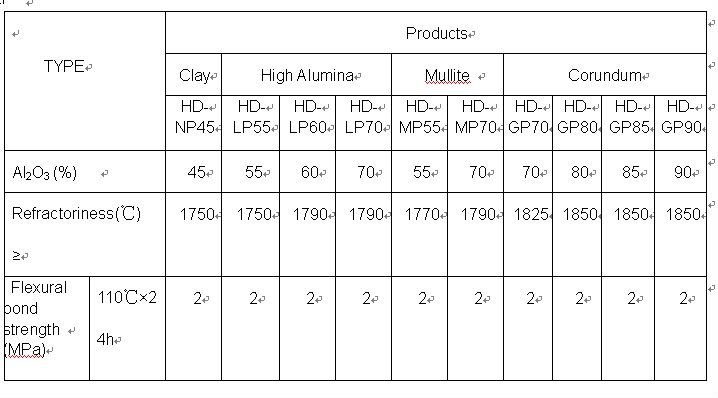

To meet the big size rotary kiln requirements, after long time research on rotary kiln refractory wearing and damage mechanism, Hongda company developed HD series rotary kiln refractory products, with advantages of good thermal stability, excellent resistance to abrasion and erosion, as well as long work life, insure the long time stable production of rotary kiln, create remarkable social and economic effects.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q: What are the materials for refractory materials? What are their names?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- Give you a list of data, you can refer to. List of required data for environmental impact assessment 1) name, type, specification and quantity of main process equipment. 2) the supply and consumption of raw and auxiliary materials (annual consumption and unit consumption of raw materials, ingredients, electricity, new water and recycled water). 3) public utilities: power supply system: need to build several substations? What is the size of the substation? Water supply system: fresh water consumption, circulating cooling water consumption, domestic water consumption, production water consumption, fire water consumption, respectively, how much? Heating system: if the project has a self heating system, the size of heating boilers, types, scale, fuel types, sources, annual consumption, the boiler's circulating water supply.

- Q: What antioxidant will be used in refractories?

- Antioxidants (Antioxidants) is the material to prevent bad influence of oxygen. It is a kind of material that can help to capture and neutralize free radicals, the category of material to remove free radicals damage to human body. Some of the body's antioxidant is self-synthesis, others is also from the food supply. Strong antioxidant such as ASTA (short for astaxanthin), etc., generally human cannot synthesize and it must be intaked from food. (1)antioxidants in the food can protect food from oxidative damage and deterioration. (2) it has the antioxidant effect in the human body's digestive tract and prevent oxidative damage in the digestive tract. (3) after being absorped, it can play a role in other body tissues and organs. (4)It is derived from certain foods that have antioxidant effect of extract and can be used as a treatment drug. Antioxidant mechanism includs chelated metal ion, scavenging free radicals, quenching singlet oxygen and removal of oxygen and inhibit oxidase activity, etc

- Q: What kind of material is refractory bauxite?

- Bauxite, also known as bauxite alumina or bauxite with high alumina, is the main raw material for the production of high alumina (aluminum content ≥48%, belongs to LAS) refractory. It must be calcined bauxite ore.

- Q: The principle of choosing fire-resistant material in Thermal Energy and Power Engineering equipment.

- What thermal equipment? The most simple principle is durable, low cost and with no environmental pollution.

- Q: What is the difference between the fire?rating and the fire resistant level of the fire-fighting equipment?

- Fire rating and fire-fighting rating are the misnomer to the building fire resistant level. The building fire risk is measured by fire resistant level. The article 3.2.1 and 5.1.7 of "Architectural design code for fire protection" have made provision respectively on the fire resistant level of plant (the storeroom) and civil construction. Article 3.0.2 of "Code for fire protection design of tall buildings" has made provisions on the fire resistant level of tall buildings. Fire resistance rating of the building is divided into four levels. Standard of fire resistance rating is determined by the combustion performance and fire resistance of the main housing member. Level one or two are in accordance with the Article 1.0.2 in this specification.

- Q: How to make the service life of refractory materials longer?

- Take acid resistant refractory materials as example: the atmosphere should be acidic atmosphere, if used in an environment whose temperature is 1900℃, it would exacerbate the loss of refractory materials, so don’t use overloaded. Second, select the appropriate refractory materials according to the environment. For example, if its operating temperature is 1800℃, generally speaking, the normal use of it according to the instruction of refractory materials would be fine.

- Q: Could you tell me how does fire protection standard of decorative material is divided?

- Level of fire prevention materials: A grade: non-combustibility building material, almost without burning materials. A1 level: non-combustible, no flame A2, non-combustible, to measure smoke, to be qualified. B1 level: flame retardant building materials: flame retardant materials has good flame retardant effect. It is uneasy to burn when encountering open fire in the air or under high temperature and is not easy to quickly spread, and when the fire source move, it will stop burning immediately. B2 level: combustibility building materials: combustibility materials has good flame retardant effect. It will immediately burst into flames when encountering open fire in the air or under high temperature. It easily leads to the spread of fire, such as timber, wooden frame, wooden beams and wooden stairs. B3 level: flammable building materials, without any flame retardant effect, easy to burn, and with a very high fire risk.

- Q: What's the commonly used refractory material for ladle?

- Commonly used types of refractory material for ladle are as follows: high-alumina brick, clay brick, magnesia-carbon brick, aluminum carbon brick, magnesia chrome brick, spinel brick, corundum brick, high alumina castables, aluminum silicon carbide carbon castables, refractory castables for ladles, magnesium castables, magnesia chrome spray coating, dry vibration materials, etc. Hope it's helpful for you!

Send your message to us

Raw Materials for Refractory:Rotaty Kiln Calcined Bauxite Powder with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords