Home Depot Aluminum Coil - Roller Coating Color Coating Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Roller Coating Color Coating Aluminum Coil Description:

We can produce aluminum sheet,color aluminum sheet and coil. They are widely used in construction

and decoration, hardware and electric appliances manufacture, automobile manufacture and other

industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting,

lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of

disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

Roller Coating Color Coating Aluminum Coil is free from Oil Stain, Dent, Inclusion, Scratches, Stain

, Oxide Discoloration, Breaks,Corrosion, Roll Marks, Dirt Streaks and other defect which will

interfere with use. Double-faced brushed and painted aluminum has a rough style and clear texture

, Brushed finish with short hairline, Precise color control and uniformity, fade free, resistant to scratch,

never flake or peel, sapphire level rigidity .

2.Main Features of Roller Coating Color Coating Aluminum Coil :

Plain Aluminum Coil

PE Coating Aluminum Coil

PVDF Coating Aluminum Coil

Embossed Aluminum Coil

Aluminum Stripe

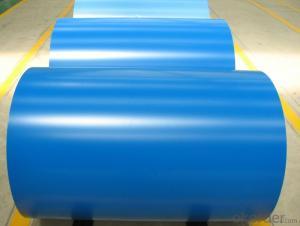

3. Roller Coating Color Coating Aluminum Coil Images:

4. Roller Coating Color Coating Aluminum Coil Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- Go with aluminum seamless gutter ,plastic only comes in 10 ft lenghts so you would have more seams which means more chances of it leaking A easy formula to figure out whataluminumn gutter will cost is and it goes by linear footage so measure your house where gutters would go and then add 12 LF for each downspout you will need about 4 and you have the total and if you call a contractor they will give you a free estimate but it should cost you about $2-$3 a Linear foot everyone is hurting for work so get a couple bids and go back and forth for the best price Also leaf guard is expensive about $4 a LF look for similar products that are cheaper hope this helps

- Q: Can aluminum coils be used in aerospace applications?

- Indeed, aerospace applications do make use of aluminum coils. The aerospace industry extensively utilizes aluminum due to its lightweight nature and impressive strength-to-weight ratio. Aircraft structures, including fuselages, wings, and landing gear, often incorporate aluminum coils. Moreover, heat transfer and cooling systems also benefit from their presence. The exceptional corrosion resistance and high thermal conductivity of aluminum coils render them fitting for diverse aerospace purposes. Furthermore, their malleability and ease of fabrication enable the creation of intricate shapes and designs necessary for aerospace components.

- Q: How do aluminum coils perform in applications where high strength is required?

- Aluminum coils are known for their excellent performance in applications where high strength is required. Despite being a lightweight material, aluminum possesses remarkable strength properties that make it an ideal choice for various industries. One of the key factors contributing to the high strength of aluminum coils is their alloy composition. Aluminum alloys can be tailored to enhance their strength by adding elements such as copper, magnesium, and zinc. These alloying elements form intermetallic compounds, which significantly increase the strength of the aluminum without compromising its overall weight. Additionally, aluminum coils undergo various manufacturing processes, such as hot or cold rolling, to further enhance their strength. These processes align the grain structure of the metal, making it stronger and more resistant to deformation. The resulting aluminum coils can withstand high stresses, making them suitable for applications that require durability and reliability. Moreover, aluminum coils exhibit excellent corrosion resistance, which further contributes to their performance in high-strength applications. Aluminum naturally forms a protective oxide layer on its surface, which prevents corrosion and ensures long-term durability. This corrosion resistance is crucial in environments where high-strength materials are exposed to moisture, chemicals, or harsh weather conditions. Furthermore, aluminum coils offer exceptional thermal conductivity, allowing for efficient heat dissipation in applications such as heat exchangers or radiators. This property is vital in industries where high-strength materials must also handle high temperatures, as it helps prevent overheating and subsequent material degradation. Overall, aluminum coils excel in applications where high strength is required due to their alloy composition, manufacturing processes, corrosion resistance, and thermal conductivity. Their combination of strength, lightweight design, and durability makes them a preferred choice in various industries, including automotive, aerospace, construction, and electrical.

- Q: What are the standard dimensions for aluminum coils?

- The standard dimensions for aluminum coils vary depending on the specific application and industry requirements. However, common dimensions for aluminum coils include widths ranging from 36 inches to 72 inches and thicknesses ranging from 0.018 inches to 0.125 inches.

- Q: Are there any restrictions on the coil length of aluminum coils?

- Yes, there are restrictions on the coil length of aluminum coils. The maximum coil length is typically determined by the capabilities of the equipment used for coil production and handling. Factors such as the size and capacity of coil winding machines, transportation and storage limitations, and the weight and stability of the coil itself all play a role in determining the maximum coil length. Additionally, longer coils may be more prone to handling and logistical issues, such as increased risk of damage during transportation or difficulties in uncoiling and processing. Therefore, it is important to consider these restrictions and limitations when determining the appropriate coil length for aluminum coils.

- Q: I have a electrical project to do, and could save about $300.00 by using aluminum wire since I can get it free, but I have never used aluminum before, and am not sure if it is a good way to go.

- I would not recommend it. Aluminum wire expands and contracts a great deal causing the connections to become loose, or break. That is what I was taught.

- Q: Are aluminum coils recyclable?

- Indeed, recyclability applies to aluminum coils. As one of the most easily recyclable substances, aluminum can be recycled ceaselessly without compromising its integrity. The process of recycling aluminum coils entails melting them down to create fresh coils or alternative aluminum goods. This practice not only diminishes landfill waste but also conserves energy and resources necessary for manufacturing new aluminum from primary materials. Opting for the recycling of aluminum coils is an environmentally conscious decision that aids in the preservation of natural resources and the mitigation of greenhouse gas emissions.

- Q: What are the different alloy compositions used in aluminum coils?

- There are several different alloy compositions used in aluminum coils, including 1xxx series (pure aluminum), 3xxx series (aluminum-manganese), 5xxx series (aluminum-magnesium), and 8xxx series (aluminum-lithium). Each alloy composition offers unique properties and characteristics, making them suitable for various applications in industries such as automotive, construction, and aerospace.

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. However, it is important to follow proper surface preparation and use a suitable paint that is compatible with aluminum to ensure a long-lasting and durable finish.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Aluminum coils are indeed appropriate for the production of beverage cans. Aluminum is the favored material for this purpose because of its numerous beneficial characteristics. To begin with, aluminum is lightweight, enabling easy transportation and handling. This is especially crucial in the beverage industry, where a substantial number of cans are manufactured and distributed. Furthermore, aluminum possesses high malleability, allowing it to be shaped into the desired form without compromising its structural integrity. This quality makes it perfect for the manufacturing of cans, as it can be effortlessly molded into the cylindrical shape required and withstand the pressure exerted by carbonated beverages. Moreover, aluminum is non-toxic, ensuring that it does not contaminate the beverages stored within the cans. It also acts as a protective barrier against light, oxygen, and moisture, effectively preserving the flavor and quality of the beverages. Additionally, aluminum is recyclable, thus making it an environmentally friendly option for can production. The recycling process for aluminum consumes significantly less energy than the production of new aluminum, rendering it a sustainable material choice. In summary, the appropriateness of aluminum coils for beverage can manufacturing is evident due to their lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

Send your message to us

Home Depot Aluminum Coil - Roller Coating Color Coating Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords