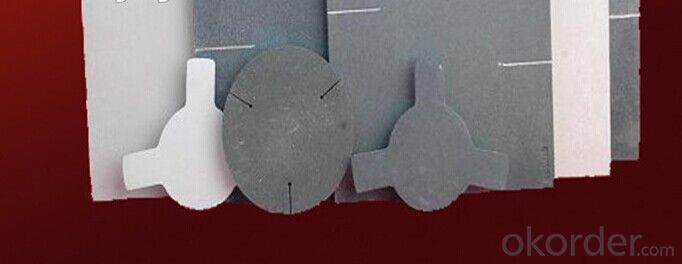

High-Quality Raw Materials for Refractory SIC Plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.ISO certificated

2.Max temperature: 1600C

3.High thermal conductivity

1.High temperature tolerance 2.Corrosion resistance 3.Oxidation resistance. 4.Wear resistance.

Application

The products are mainly of kiln furniture in the manufacture of high tension ceramic insulator, construction ceramics, sanitary wares and domestic ceramics. Also, recystallized carbide refractories are widely used in metallurgy, chemical industries for its unique, excellent properties, the product has up to the advanced intentioned standard.

Specification

Item | Index |

Bulk Density, g/cm3 | ≥2.65 |

Porosity , % | ≤ 16 |

rupture strength 1400°C, MPa | ≥100 |

Thermal Conductivity, w/m.k | 24 |

Elastic modulus, GPa | 250 |

compression strength, MPa | ≥600 |

a—SiC , % | ≥99 |

Max. Service Temperature , C | 1650 |

1.aluminium industry

2.precision casting

3 refractory materials

4.aluminum silicate refractory fiber for fiber blanket, refractory brick .

5. refractory cement

Bauxite is an aluminium ore and is the main source of aluminium.

Bauxite is used in cement, chemicals, face makeup, soda cans, dishwashers, siding for houses.

- Q: How to use fire-resistant soil?

- In fact, the refractory soil is not strong. Refractory soil is clinker, there is no strength, also known as "blade mud", he is used as filling materials, the use of thickness generally not more than 3mm. Therefore, the furnace insulation can not be done.Civil boiler interior insulation, you can use "high aluminum cement", also known as refractory cement on it.

- Q: What's the fire?retardant material of roller shutter fire resistance door ?

- It is composited by inorganic materials, and main componets are perlite and inorganic adhesive, etc.

- Q: What kind of material is refractory fiber?

- Refractory fiber, also known as ceramic fiber, is fibrous thermal insulation refractory. It has the characteristics of ordinary fibers, such as softness, flexibility, having a certain tensile strength. And it can be further processed into a variety of products such as paper, wire, rope, tape, blankets and felts.

- Q: What is the use of refractory?

- Some is insulated for personnel safety, some is to save heat loss and conserve energy, and some is used as lining of kilns. Because of its light weight, I recommand it to you and I am engeged in ceramic fiber, just an advertisement.

- Q: Does the refractory material used in steelmaking all refer to refractory brick?

- Besides refractory brick, it also refers to unshaped refractories like fire clay and castables.

- Q: Which one is better, fire-resistant wood or steel?

- From the aspect of low-carbon and environment protection, the steel and timber structures are both OK, they are both renewable resources, the steel can be recycled and melt down again and wood can continue to be planted. Fireproof board Fireproof board is a refractory material used for surface decoration. It is widely used in interior decoration, furniture, kitchen cabinets, laboratory tables, walls, and other fields.

- Q: Fefractory of aluminium oxide.

- It can be refined into castable refractory and refractory bricks, according to temperature rating. There are shaped refractory material and shapeless refractory material, and ceramic fiber. So it must be specific. There is a large range of refractory, which basically contains the aluminium oxide.

- Q: What's the fire resistance test method of doors and roller shutters?

- Fire resistance test method of doors and roller shutters: This standard specifies the fire resistance test method for roller shutter doors under standard fire conditions. The method is used to test the fire resistance of the ventilating duct when bearing the external fire (A duct) and internal fire (B duct). Fire resistance test of vertical ducts may be conducted referring to this standard. 1.Test specimen1.1 The test specimen is obtained by cutting from any part of the qualified metal tube unless otherwise relevant standard or mutual agreement specifies the cutting position of the metal tube. 1.2 Length of the specimen: L≈2.5D+50mm (D: outer diameter of the metal tube). The cut surface of the specimen must be perpendicular to the axis of the metal , and the seamed edge of the cut should be round off. Test method GB243-82 of metal tube necking 2. Test procedures 2.1 In the test, punch or press the metal tube into the tapered conical seat (see Figure) with a hammer or press machine, and make it uniformly diminished to the regulated shrinkage X which is calculated according to the following formula: Test method GB243-822 for metallic pipe necking: The inner wall of the seat cover used in the test should be polished, and has certain hardness and is coated with lubricating oil. Its conicity is 1:10, 1:5 or others in accordance with relevant standard provisions. If there is no provision, then adopt the conicity of 1:10. This standard is not suitable for: a) The pipeline whose fire resistance depends on the fire resistance of the ceiling; b) The pipeline with access door, unless otherwise the access door is included into the pipeline and tested together; c) The pipeline with two or three sides; d) Fume exhaust pipes;

Send your message to us

High-Quality Raw Materials for Refractory SIC Plate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords