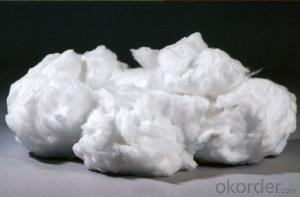

Glass Wool Refractory Material Ceramic Fiber from Clay Clinker

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 500 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characteristics:

Low heat capacity and low thermal conductivity;

Excellent chemical stability;

Excellent thermal stability, resistance to pulverization at high temperature;

With no binders or corrosive substances;

Excellent sound absorption

Typical Application:

Raw material for fiber blanket, board products;

Raw material for fiber textile products;

Fillings for wall lining gap in high temperature furnace, heating device;

Raw material wet processed products;

Fiber spraying;

Castables;

Raw material for coatings;

Insulation fillings for corner and complex space.

More details about ceramic fiber blanket:

Item | Ceramic Fiber Blanket |

Size and Specifications | Density: 96kg/m³,128kg/m³,160kg/m³ Thickness:6mm,13mm, 19mm, 25mm, 38mm, 50mm |

Characteristics | (1) Excellent chemical stability; |

Typical Use | (1) Industrial furnace wall lining; |

Operating Temperature | 1050°C |

Service | The specifications of the ceramic fiber wool blanket could be customized |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash |

Packing | inner plastic bag + outer pallet or carton |

Delivery | Within 15 Days |

Certificate | CE, ISO 9000, TUV |

- Q: What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q: Whether the combustion performance of glass wool blanket can reach A grade

- Glass wool and rock wool are commonly grouped into the category of A grade fireproof material .

- Q: What are the advantages and disadvantages of centrifugal glass wool?

- Rubber insulation material and centrifugal glass wool board both have their own advantages. Rubber is of foam texture, soft and delicate, mainly used for air conditioning, whose construction is simple. Centrifugal glass wool board is fiber product, so human body will be allergic, whose temperature endurance is 400 degrees with good thermal insulation effect, mainly used in buildings and underground pipes. They are thermal insulation construction products approved by fire control department .

- Q: what's the differences between glass wool roll mat and rock wool roll mat? does glass wool roll mat have any mandatory retest requirements or environmental requirements?

- Steel structure roof basically uses glass wool roll mat, because rock wool roll mat is six to ten times heavier than glass wool roll mat, light steel frame can't bear so much gravity, glass wool is more fluffy than rock wool, so it's thermal insulation effect is better, glass wool is cheaper than rock wool, the glass wool fire rating is A-level flame retardant, now people won't use the rock wool blanket, wall thermal insulation used rock wool board.

- Q: Behind the wall at the head of bedroom is an elevator, but how can indulate sound? Waht do you think if install silicic acid board of 12 centimeters plus glass wool and splint fo 9 centimeters and then nail soft package background in the rear?

- 1, It is advisable to buy another house because this case autually attirbutes to serious defect of the housing design. 2, You can try to change the bed to the opposite direction. 3, If adopted sound proof wall, you can refer to the pictures I offered. 4, Using board of 9cm can effectivley reduce low frequency noise of elevator.

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- Foam is the mainly material, now with the increase of rock wool, the rock wool can be fireproofing and sound absorption, it may also lay glass wool in the interior of color steel?plate and the function is sound absorption and thermal insulation.

- Q: What's the types of glass wool points? do they have the same sound insulation effect?

- Mineral wool and rock wool basically

- Q: What is the difference between red glass wool and yellow glass wool in terms of technical parameters?

- The majority of glass wools are yellow, while glass wools with the color of red or other are called color glass wool which are rarely used.

- Q: Whose thermal insulation performance is the best between glass wool felts and cystosepiments?

- personally I believe that foamed concrete thermal insulation boards are better.

- Q: How to construct when apply rock wool board to glass curtain wall?

- Base treatment--Coat interfacial agent on both sides of rock wool boards and the side - hang vertical line and flip the controlling line- Paste rock wool boards with the adhesive- Plastering the first rendering coat mortar--Pressing the alkali-resistant glass fiber mesh in it-- Anchoring rendering coat mortar composite alkali-resistant glass fiber mesh--Plastering the second rendering coat mortar and press alkali-resistant glass fiber mesh into it-- Plastering the third rendering coat mortar

Send your message to us

Glass Wool Refractory Material Ceramic Fiber from Clay Clinker

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 500 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches