Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

light insulation brick

1. refractories

2. silica insulation brick

3. light insulation brick

4. glass furnace

Refractory mullite insulating refractory brick JM 23

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

Product Description

Light insulation brick

Description

The insulating firebricks are made from high purify raw materials and follows the ASTM C155 classification. These IFB’s contain a carefully graded organic filler which is burned out during firing to give a uniform controlled pore structure and after are machined to precise tolerances on all surfaces.

Features

- Use limit up to 1760°C

- Excellent strength and thermal stability

- Low thermal conductivity

- Low Heat Storage

- High Purity

- Very big range of available sizes and formats

- Very accurate dimensions

Applications

Recommended as hot face and backup insulation in all industries and applications.

Special Shapes

In addition to the standard brick sizes, our bricks are available in pre-machined special shapes as well as Suspended Roof Blocks!

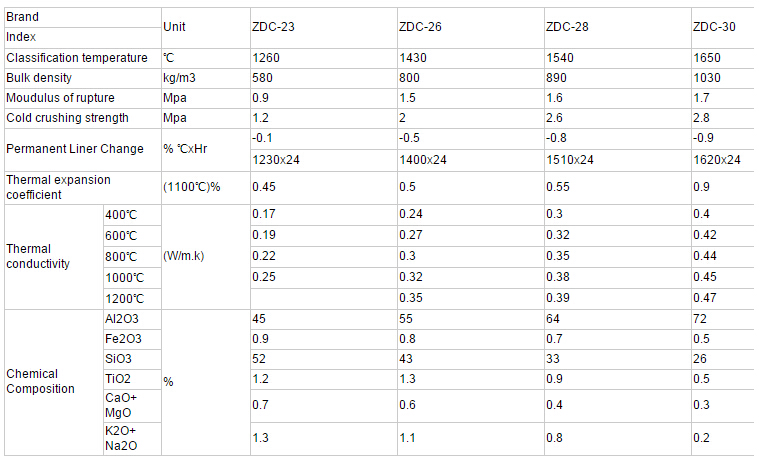

Technical Specification:

- Q: Are insulating fire bricks resistant to insect infestation?

- Insulating fire bricks do not possess specific resistance against insect infestation. They are primarily utilized for their thermal insulation properties in applications involving high temperatures, such as kilns, furnaces, and fireplaces. Although they are generally not prone to insect damage, they are not entirely impervious to it either. Insects can still infiltrate the bricks if they discover small cracks or openings in the material. Nevertheless, insulating fire bricks are typically dense and compact, thereby making it challenging for insects to burrow or establish nests within them. It is always advisable to employ preventive measures for managing and eliminating potential insect infestations in any construction material, including insulating fire bricks, to ensure their durability and effectiveness.

- Q: Can insulating fire bricks be used as insulation in walls and roofs?

- Yes, insulating fire bricks can be used as insulation in walls and roofs. They have excellent thermal insulation properties, high heat resistance, and are specifically designed for use in high-temperature environments.

- Q: Can insulating fire bricks be used for insulation in sewage treatment plants?

- Yes, insulating fire bricks can be used for insulation in sewage treatment plants. These bricks are designed to withstand high temperatures and provide excellent thermal insulation. They can be used to line the walls, floors, and ceilings of sewage treatment plants to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks have good resistance to chemicals and moisture, making them ideal for use in environments with high levels of humidity and corrosive substances found in sewage treatment plants.

- Q: Are insulating fire bricks suitable for insulation in steam boilers?

- Insulating fire bricks, which are made from lightweight materials such as alumina or silica, are highly suitable for providing insulation in steam boilers. These bricks possess exceptional insulating properties and can endure high temperatures and thermal shocks, making them an ideal choice for use in steam boilers subjected to constant heat exposure. The low thermal conductivity of insulating fire bricks effectively hinders heat transfer, resulting in reduced energy loss and enhanced efficiency of steam boilers. Additionally, their superior insulation capabilities assist in maintaining consistent temperatures within the boiler, preventing fluctuations in heat and minimizing the risk of thermal stress and damage. Moreover, insulating fire bricks exhibit resistance against corrosion and chemical attacks, ensuring their longevity and durability when employed in steam boiler applications. Furthermore, they can be effortlessly installed and cut into various shapes and sizes to perfectly fit the specific requirements of the boiler. In conclusion, insulating fire bricks are an exceptional option for insulation in steam boilers due to their ability to withstand high temperatures, low thermal conductivity, and resistance to corrosion. Their utilization aids in reducing energy loss, improving efficiency, and guaranteeing the long lifespan of the boiler.

- Q: How do insulating fire bricks affect the overall insulation properties of a structure?

- Insulating fire bricks greatly enhance the insulation properties of a structure due to their low thermal conductivity. These bricks effectively minimize heat transfer and prevent the escape of heat, resulting in improved energy efficiency and reduced heating costs. Additionally, their high resistance to heat and excellent thermal stability contribute to maintaining a consistent and comfortable indoor temperature.

- Q: What is the typical cost of insulating fire bricks?

- The typical cost of insulating fire bricks can vary depending on several factors such as the size, quality, and quantity needed. On average, you can expect to pay anywhere between $2 to $10 per brick. However, keep in mind that this is just a general range, and prices can be higher or lower depending on where you purchase them from and the specific requirements of your project. It is always a good idea to compare prices from different suppliers to ensure you are getting the best deal.

- Q: Can insulating fire bricks be used in refractory castings?

- Indeed, refractory castings can incorporate insulating fire bricks. Due to their lightweight nature and exceptional insulation abilities, insulating fire bricks are ideal for tasks that demand thermal insulation. Such tasks include the creation of linings in furnaces, kilns, and other equipment that operates at high temperatures. To achieve thermal insulation and minimize heat loss, insulating fire bricks can be utilized either as a layer or as an element within the refractory casting mixture. Furthermore, their low thermal conductivity aids in reducing energy consumption and sustaining elevated temperatures within the casting.

- Q: Can insulating fire bricks be used for insulation in smelters?

- Yes, insulating fire bricks can be used for insulation in smelters. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials that have low thermal conductivity, allowing them to effectively retain heat and minimize heat loss. This makes them ideal for use in smelters, where maintaining high temperatures is crucial for efficient metal smelting processes. Additionally, insulating fire bricks are resistant to chemical attack and mechanical stress, ensuring their durability and suitability for use in harsh smelting environments.

- Q: How do insulating fire bricks handle moisture?

- Insulating fire bricks are designed to handle moisture quite effectively. They have low porosity and are made of materials that are resistant to water absorption. This allows them to retain their structural integrity even when exposed to moisture or high humidity levels. Additionally, their insulating properties are not significantly affected by moisture, making them suitable for various applications where moisture resistance is required.

- Q: Are insulating fire bricks resistant to chemicals?

- Insulating fire bricks, in general, exhibit resistance to chemicals. They are specifically engineered to endure extreme temperatures and possess minimal thermal conductivity, making them a prime selection for chemical-related applications. These bricks are typically composed of ceramic materials, such as alumina, renowned for their exceptional chemical resistance properties. Nonetheless, it is crucial to recognize that the extent of chemical resistance can fluctuate based on the specific variant of insulating fire brick and the chemicals involved. Certain chemicals, particularly those highly corrosive or reactive in nature, may still inflict harm or deterioration on the bricks over time. Thus, seeking detailed information on the chemical resistance capabilities of specific insulating fire bricks from the manufacturer or supplier is highly recommended.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords