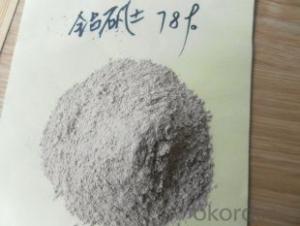

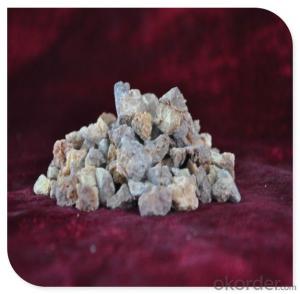

Raw Materials for Refractory:DBM Dead Burnt Magnesite 97%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory DBM Dead Burnt Magnesite 97%

Specifications

1.Feed additive

2.Fertilizer for Soil Remediation

3.Water Treatment and paper

4.Making Portland Cement

5.For abrasive wheel

Kind | Brand | Chemical Composition % | Grain size (mm) | ||||||

MgO Min. | SiO2 Max. | CaO Max. | Fe2O3 Max. | B.D Min. | |||||

High-Purity Magnesite Sinter | DBM-96 | 96 | 1.0 | 1.4 | 0.8 | 3.25 | 0~30 | ||

DBM-97B | 97 | 0.7 | 1.4 | 0.8 | 3.25 | ||||

DBM-97A | 97.5 | 0.6 | 1.2 | 0.7 | 3.30 | ||||

DBM-98 | 97.7 | 0.5 | 1.2 | 0.5 | 3.30 | ||||

Our Lab

Our Service:

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: How many kinds of fireproof materials are there in the market?

- rock wool board? inorganic thermal insulation mortar? glass wool board? expanded glass? ceramic foam plate? sand aerated concrete? haydite concrete? foam cement? vitrified micro bubble panel

- Q: how to use boiler fireclay

- Boiler refractory, diluted with water to touch the places where needed, can be used after high temperature baking.

- Q: How is the division of the fire resistant level of the rock wool board?

- It's like this: China's national standard GB8624-97 divides the combustion performance of building materials into the following grades. Level A: non-flammable building materials. Level B1: flame-retardant building materials. Level B2: combustible?building?materials. Level B3 flammable building materials. section II Combustion performance and fire endurance of building components. First, The combustion performance of buildings of building components. The building is composed of components, such as foundation, walls, lubrication columns, beams, plates, roofs and stairs, ect. Building components are constituted by the building materials, whose combustion performance depends on the combustion properties of the used construction materials. Section One Combustion performance of building components. The building components are divided into three categories according to their combustion properties. First, non-combustible component: the component made by incombustible?materials. The incombustible?material refers to that when meeting the Oxygen in the air, it will not burn.

- Q: What kind of material is good for cabinet fireproof board

- Natural stone marble: Advantage: Rich color, texture is more soft, easy for cutting or molding; shortcomings: Because it is a natural formation, micro cracks will get easily broken. If sewage infiltrates in during production and transportation, it is difficult to clean and it will get cracked. In the daily cleaning, residue will be filled into the cracks when using cloth to clean. then the material will become breed bacteria. In the long process of the formation, natural stone material may cause harm to human health due to the formation of heavy mental which is radioactive.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: How should refractory cement be used?

- How to use refractory cement? How to use refractory cement? Thank you.

- Q: I wanna ask what are the acidic refractories?

- You can look at these: (1) silica?brick with stronge acidity, unshaped silicious refractory, quartz glass and fused silica combined products; (2) semi-silica refractory with moderate acidity and pyrophyllite refractory; (3) clay-based refractory with weak acidity. I hope it is useful!

- Q: What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q: Detailed description of magnesia dolomite refractory material?

- The CaO of magnesia dolomite refractory is beneficial to the purification of molten steel. In the aspect of smelting clean steel, magnesia dolomite refractory also has good dephosphorization and desulfurization effect.

- Q: who knows the technology of fireproofing material?

- 1, Foam insulation board,it's the foam insulation board material made by inorganic ceramic material through high temperature roasting, and is called for short as ceramic insulation plate. 2, composite cement foaming insulation board is made by cement,fly-ash,silica fume and other main materials and it's a kind of hole-closed?lightweight hydrophobic insulation board made by the technologies of foam,maintenance,cutting processing. 3, gypsum foam thermal insulation board is inorganic thermal insulation board that takes industrial by-product gypsum as the main raw material, modify the gypsum through physic modified principle, then foam, casting and cutting through chemical foam principle. 4, aerated concrete panel is made by lightweight material,silicious material, foaming?agent and other raw materials and it's a kind of lightweight concrete plate material made by the high pressure steam of manufacturing technique. 5, rock wool board is made by natural igneous rock and other main materials, and it's a kind of plate with thermosetting resin as binder made through melting in high temperature and centrifugation.

Send your message to us

Raw Materials for Refractory:DBM Dead Burnt Magnesite 97%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords