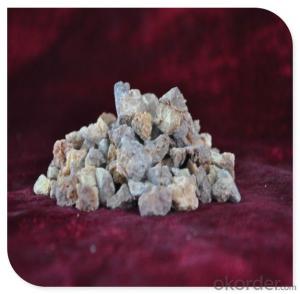

Raw Materials for Refractory:90% MgO Dead Burnt Magnesite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory 90percent MgO Dead Burnt Magnesite Price

Dead Burned Magnesite

Description

Dead Burnt Magnesite is produced in the Rotary Kiln by sintering raw magnesite at a controlled temperature of 1750 degree centigrade and its chemically inactive. Dead Burnt Magnesite is consume almost exclusively in the production of Refractory Field.

Dead Burnt Magnesia Application:

1. Refractory Industry for manufacture of Basic Refractory Bricks .

2. Manufacture of Ramming Mass composition, Fettling material and Magnesite Mortar.

3. It is used in SLAG beneficialness and in SLAG splashing in Arc Furnaces.

4. It is also used as a coating material in Steel Industry.

MgO ≥ | CaO ≤ | SiO2 ≤ | L.O.I. ≤ | BD ≥ g/cm3 | size mm | |

VT-MGO-DBM 87 | 87 | 2.2 | 7.0 | 0.5 | 3.1 | according to the requirement of customer |

VT-MGO-DBM 90 | 90 | 2.2 | 5.0 | 0.3 | 3.15 | |

VT-MGO-DBM 91 | 91 | 2.0 | 4.5 | 0.3 | 3.18 | |

VT-MGO-DBM 92 | 92 | 1.8 | 4.0 | 0.3 | 3.18 | |

VT-MGO-DBM 93 | 93 | 1.6 | 3.5 | 0.3 | 3.18 |

Our Lab

Our service

Large production capacity(20000-tons per month) ensure the fast production cycle after confirmed the order.

Produce the products according to clients' requirements.

Professional Packing,Avoid damage;Competitive Price,Make the products competitive in your market.

Provide 24 hours'consultation service.We are ready to answer our consultations at any time.

- Q: What is the importance of silicon powder in refractory processing?

- it can certainly improve the fire resistance

- Q: Who knows about roof fireproofing materials?

- At present, only phenolic foam boards can meet requirements. The test temperature can be 2,000 degrees, and there is no molten droplet during the tests and it can maintain integrity. heat conductivity coefficient: 0.03W / (mk), non-combustible, non-toxic, smokeless!

- Q: How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- The fly ash effect will continue to play a role in a considerable period of time, so the long-term strength keeps strengthening, the average age of 90 days of strength will grow 80%-100% more than the 28 days.

- Q: Who knows what is the standard of insulation material whose fire proof is level A?

- Fire insulation materials of level A is non combustible building materials, and does not have any burning material. Level A1: single inorganic non combustible, no open flame. Level A2: A2 level: composite organic non combustible, that is, composite materials, non flammable, smoke volume should reach the standard.

- Q: I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- which level is b1 fireproof and thermal inuslation matertial: I soppose you mean rubber and plastic! Only rubber and plastic has b1b2 level. Level b1 is the fireproofing level b1, because the rubber and plastic does not belong to the fireproofing material. It only has fire?retardant. The wholesale of all kinds of thermal insulation material and construction needs to look at the name.

- Q: How many refractory materials does the annual output of 1 million tons of coke oven require?

- Refractory material is an important material used in iron and steel industry, it is mainly used in steel-making furnace, furnace lining, loading and transportation of metal and slag ladle lining, the furnace lining procedure of billet heating, heat conduction and lining of blast furnace and the flue. So, to put it simply, we can think of it as a structural material, which can withstand a temperature of 260-1760 degrees centigrade.

- Q: What's the refractory material in common use currently?

- According to its category, raw material of basic refractory: Mainly magnesite (magnesia), dolomite, lime, olivine, serpentine, high alumina material (sometimes neutral); main neutral raw material: chromite, graphite, silicon carbide (artificial).

- Q: What refractories can withstand high temperature above 2100 degrees?

- Usually a dryer will not have such a high temperature. I do not know what you would use it for. Refractory cement coupled with quartz sand can work for 4 to 5 hours. So you can try cement coupled with corundum or superfine bauxite for better effect.

- Q: who knows the technology of fireproofing material?

- 1, Foam insulation board,it's the foam insulation board material made by inorganic ceramic material through high temperature roasting, and is called for short as ceramic insulation plate. 2, composite cement foaming insulation board is made by cement,fly-ash,silica fume and other main materials and it's a kind of hole-closed?lightweight hydrophobic insulation board made by the technologies of foam,maintenance,cutting processing. 3, gypsum foam thermal insulation board is inorganic thermal insulation board that takes industrial by-product gypsum as the main raw material, modify the gypsum through physic modified principle, then foam, casting and cutting through chemical foam principle. 4, aerated concrete panel is made by lightweight material,silicious material, foaming?agent and other raw materials and it's a kind of lightweight concrete plate material made by the high pressure steam of manufacturing technique. 5, rock wool board is made by natural igneous rock and other main materials, and it's a kind of plate with thermosetting resin as binder made through melting in high temperature and centrifugation.

- Q: How long is the fire endurance of fire resistant rolling shutter door?

- According to fire endurance, fire doors can be divided into Class A, Class B and Class C fire doors, whose fire resistance should be no less than 1.20h, 0.90h and 0.60h respectively. You can use fire resisting shutters to seperate fire?compartments in places where it is difficult to set firewalls. When using the fire resisting shutter with unexposed surface temperature rise as fire endurance conditions, its fire endurance should be no less than 3h. But when using the fire resisting shutter without unexposed surface temperature rise as fire endurance conditions, you should set independent protection of closed automatic water spray system at two sides of the shutter, and the duration of water spraying should be no less than 3.0h. I hope it's useful.

Send your message to us

Raw Materials for Refractory:90% MgO Dead Burnt Magnesite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords