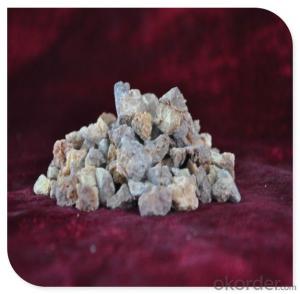

Refractory Raw Materials - Dead Burnt Magnesite MgO 90%

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DBM-is produced using selected natural magnesite that is purified and is calcined in a shaft kiln.The final product is used for electric furnacefloors and furnace liner tamping.

Many typical specification as following :

Grade | MgO (min.) | SiO2 (max.) | CaO (max.) | Fe2O3 (max.) | Al2O3 (max.) | L.O.I. (typical) |

mesh |

DBM90 | 90.00% | 1.00% | 1.50% | 0.70% | 0.10% | 1.70% |

0-400 |

DBM95 | 95.00% | 1.00% | 1.50% | 0.80% | 0.10% | 2.60% | |

DBM96 | 96.00% | 1.50% | 2.50% | 0.80% | 0.30% | 2.90% | |

DBM97 | 97.00% | 3.00% | 2.50% | 0.80% | 0.30% | 3.40% |

Packaging & Shipping of DBM :

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Application of DBM:

1.Mainly used in processing raw materials of different magnesia refractory,

2.The production of steel lining the bottom and ramming mixes;

3.The raw materials of magnesia brick and magnesia-chrome brick;

4.Used electric steel making furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages:

1) We have subsidiary plants doing metallurgical materials;

2) For some product, we do trading, while we can control the quality and cost due to our strong capacity and cash flow in China;

3) Our logistics and freight charge is lower than others since we have big quantity cargo to be exported in some main ports China;

4) We have strict and mature quality and logistics control on the cargo;

5)As a governmental company, we are reliable.

- Q: Does anyone know the characteristics of refractory for glass kiln?

- Refractory is a kind of non-metallic material with refractoriness not less than 1580 ℃, which has better thermal shock resistance and chemical erosion resistance, low heat conductivity coefficient and low expansion coefficient. Refractoriness is the centigrade?temperature of refractory cone specimen wiyhout any load resisting high temperatures without melting down Refractory is widely used in industries like metallurgy, chemical, petroleum, machinery manufacturing, silicates, power, etc., which is mostly used in the metallurgical industry, accounting for 50% to 60% of total output.

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- according to China's national standard GB8624-97, the combustion performance of construction materials can be divided into several classes: Class A: Incombustible building material: Almost no burning material. Class B1: nonflammable building material: nonflammable material has a good flame resistance effect. when it meet the open fire in the air or burnd at high temperature, it is difficult to spread quickly, and when the fire source is removed, the combustion stop immediately. Class B2: flammable building material: flammable material has a good flame resistance effect. when it meets open fire in the air or at high temperature, it will immediately burst into flames and easily cause fire spread, such as wooden column, timber roof truss, timber beam, and wooden stairs,ect.. Class B3: inflammable building material: No flame resisting effects, highly flammable, high fire risk.

- Q: How to deiron refractory?

- It cannot be done in conventional approaches, because you are referring to refractories. If using acid liquor soaking method to deiron, the material itself will be also damaged! If just for reducing the corrosion of materials, it will be OK to add a corrosion-resistant and fireproof protection layer.

- Q: What does refractory mean?

- Basic refractory material generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials. This kind of refractory material has higher refractoriness and strong resistance to alkaline slag.

- Q: How many kilns using refractories are needed? What are the furnaces respectively?

- There are many magnesia-chrome bricks and alkali insulation tiles); aluminum manufacturer roaster; The bottom of the glassworks regenerative chamber generally use the clay checker bricks, which is popularly used in many places of the steel mill. the upper of the power plant uses low pore brick and magnesia bricks. The forehearth uses the corundum bricks, and the cement plant uses dry and wet rotary?kiln (silmo brick

- Q: Fefractory of aluminium oxide.

- Do you mean the alumina hollow ball brick? We can exchange private messages in specific.

- Q: what textures of furnace refractories are good?

- Common ceramics use ordinary clay and high alumina bricks, as well as thermal insulation bricks, calcium silicate boards and fiber cotton. The vessels fired with potter's earth are called pottery, and the vessels fired with porcelain clay are called porcelain. Ceramic is generic term of pottery, stoneware and porcelain. The objects taking the two different types of clay as the raw materials, like, potter's earth and porcelain clay, and made through the technological process of ingredients, forming, drying and roasting, ect. can be called ceramics.

- Q: What's the A grade fireproofing material?

- 1. fire-proof plate; 2. fireproof wooden door; 3. fireproof wooden window frame; 4. fire resisting shutter; 5. fireproof and mothproof wood; 6. fireproof glove compartment; 8. fire?retardant?coating; 9. fire-proof?sealing?material.

Send your message to us

Refractory Raw Materials - Dead Burnt Magnesite MgO 90%

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords