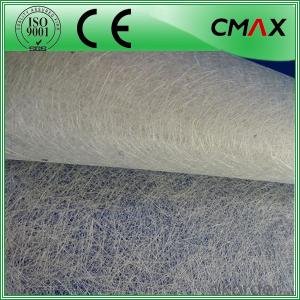

Ppg Chopped Strand Fiberglass Reinforced Raw Materials Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Chopped strand mat is made from chopped glass fibers, which are bonded with powder or emulsion binders. It can be used in hand lay-up process and continuous laminating process to produce FRP products, such as plates, lighting board, hull, bathtub, cooling towers, anti-corrosion materials, vehicles.

Features:

Uniform thickness, softness and hardness good.

Good compatibility with resin, easy completely wet-out.

Fast and consistent wet-out speed in resins and good manufacturability.

Good mechanical properties, easy cutting.

Good cover mold, suitable for modeling complex shapes.

Application:

fiberglass thickness is suitable for application by hand lay-up, reinforce and machine FRP molding,

including interior decoration of vehicles, boat hulls, complete set of sanitary equipment, anticorrosive pipes, tanks, building materials, tables, chairs, panels and all kind of composite FRP products.

Specifications:

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Special products are available according to customer’s requirement.

Product Packaging:

Each Surface Tissue is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 330mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Product Storage:

Unless otherwise specified, Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

Order Information

Ordering please specify:

1. the product code, 2. weight, 3. width, 4. order quantity, 5. packaging, 6. special requirements please specify.

FAQ:

1. How long will you get reply?

Any inquiry will be replied within 24 hours. Usually we will reply within 12 hours.

2. How long is warranty period?

We provide 3 year warranty period.

3. What is your MOQ?

Any order quantity is available.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T, Western Union, Paypal etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

15-20 days for bulk production after confirm the order.

- Q: Is fiberglass chopped strand suitable for applications requiring high weather resistance?

- When it comes to high weather resistance, fiberglass chopped strand isn't the best choice. Although fiberglass is known for being strong and durable, chopped strand fiberglass lacks the necessary qualities to withstand harsh weather conditions for an extended period of time. Chopped strand fiberglass is commonly used in applications where mechanical strength is the main requirement, such as automotive parts, pipes, and boat hulls. However, it isn't designed to handle UV radiation, extreme temperature changes, or prolonged exposure to moisture and chemicals. If you need a material that can withstand harsh weather conditions, it's better to consider other options like reinforced plastics, specialty coatings, or composites with enhanced weatherability properties. These materials are specifically engineered to endure sunlight, temperature fluctuations, and moisture, ensuring long-lasting durability and performance in outdoor environments. To ensure high weather resistance, it's important to evaluate the specific requirements of your application and seek advice from experts or manufacturers. They can help determine the most suitable materials to achieve the level of weather resistance you need.

- Q: How does the moldability of the chopped strand affect its performance?

- The performance of the chopped strand is significantly influenced by its moldability, which is the ability of the chopped strand to adapt and conform to the shape of the mold during the manufacturing process. When the chopped strand exhibits excellent moldability, it can effortlessly assume complex shapes with intricate details. This characteristic allows for its utilization in a wide array of applications that necessitate precise molding, including automotive parts, aerospace components, and consumer goods. Conversely, if the chopped strand possesses inadequate moldability, it can lead to various performance issues. It may fail to fully conform to the mold, resulting in gaps, voids, or uneven distribution of fibers. These issues can compromise the structural integrity and strength of the final product. Moreover, poor moldability can make it challenging to achieve consistent and uniform thickness, resulting in dimensional inaccuracies and variations in the finished product. Hence, the moldability of the chopped strand plays a crucial role in guaranteeing the overall performance and quality of the final product. By carefully selecting chopped strands with excellent moldability, manufacturers can achieve superior structural integrity, dimensional accuracy, and overall performance in their molded products.

- Q: Can fiberglass chopped strand be used for electrical insulation?

- No, fiberglass chopped strand is not typically used for electrical insulation as it does not possess the necessary dielectric properties required for effective insulation.

- Q: How is the weathering resistance of fiberglass chopped strand composites tested?

- The weathering resistance of fiberglass chopped strand composites is typically tested through exposure to various environmental conditions, such as UV radiation, extreme temperatures, moisture, and chemical agents, over a specified period of time. This testing is often done using accelerated weathering chambers or outdoor exposure racks to simulate real-world conditions and determine the composite's durability and resistance to degradation.

- Q: Can fiberglass chopped strand be used in water storage tanks?

- Yes, fiberglass chopped strand can be used in water storage tanks. Fiberglass is a highly durable and corrosion-resistant material, making it suitable for water storage applications. It helps prevent leaks and contamination, ensuring the integrity and safety of the water storage tank.

- Q: What are the quality control measures for fiberglass chopped strand production?

- There are several quality control measures for fiberglass chopped strand production. Firstly, raw materials are carefully inspected and tested to ensure they meet the necessary specifications and standards. During the production process, regular sampling and testing are conducted to monitor the physical properties, such as tensile strength, moisture content, and fiber length. Additionally, visual inspections are performed to detect any defects or impurities in the chopped strands. Finally, the finished products undergo thorough quality checks to confirm they meet customer requirements before they are released for distribution.

- Q: How does the diameter of the chopped strand affect its performance?

- The diameter of the chopped strand plays a significant role in determining its performance. A smaller diameter typically results in improved performance characteristics, such as increased tensile strength and better adhesion properties. Firstly, a smaller diameter chopped strand provides a higher surface area-to-volume ratio. This increased surface area allows for better bonding with the resin matrix in composite materials, leading to enhanced mechanical properties. The smaller diameter also promotes better resin penetration, ensuring a more uniform distribution of the resin throughout the composite structure. This, in turn, improves the overall strength and structural integrity of the final product. Additionally, a smaller diameter chopped strand can contribute to a higher fiber loading in the composite. This means that a greater number of strands can be incorporated into the resin matrix, resulting in a higher reinforcement content. This increased reinforcement content enhances the stiffness and strength of the composite material, making it more resistant to deformation and failure under load. Moreover, the smaller diameter also aids in achieving a more homogeneous dispersion of the chopped strands within the resin matrix. This uniform distribution of fibers helps to prevent the formation of voids or weak spots in the composite, ensuring consistent and reliable performance. It is important to note that the diameter of the chopped strand should be selected based on the specific application requirements. While a smaller diameter may offer better performance characteristics, it may also result in increased processing difficulty or higher cost. Therefore, a balance between the desired performance and practical considerations should be achieved when choosing the diameter of the chopped strand.

- Q: what is glass fiber tank furnace drawing and what is used for?

- Glass fiber(English name is): It is a kind of excellent inorganic non-metallic materials, having the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage of poor brittleness, poor abrasion resistance. It is founding by high tempersture with the materials of glass ball and waste glass, and wire drawing, winding and weaving process for production, the filament diameter ranges from several microns to twenty micron, the equivalent of a hair 1\20-1\5, and each bundle of fibers by hundreds or even thousands of root filaments. Usually it is treated as a reinforcing material of complex materials, electrical insulating materials and insulation materials, circuit board, etc. and widely used in various fields of the national economy. The tensile strength of glass fiber is high, and the elongation is small (3%).

- Q: Can fiberglass chopped strand be used in the production of insulation blankets?

- Indeed, the utilization of fiberglass chopped strand is applicable in the manufacturing of insulation blankets. This lightweight and adaptable material possesses exceptional thermal insulation characteristics. It can be effortlessly manipulated and shaped into insulation blankets, which find extensive use in diverse industries for thermal and acoustic insulation objectives. The incorporation of chopped strands effectively augments the overall insulation efficacy of the blankets, forming a compact and consistent layer of insulation material. Moreover, fiberglass chopped strand exhibits resistance against moisture, chemicals, and fire, thus rendering it an optimal selection for insulation applications.

- Q: How does fiberglass chopped strand affect the weight of products?

- Fiberglass chopped strand can significantly reduce the weight of products due to its lightweight nature. The strands of fiberglass are chopped into smaller pieces, which can be mixed with resins or other materials to form composite products. This incorporation of fiberglass chopped strand helps to reinforce the overall structure while keeping the weight of the product relatively low.

Send your message to us

Ppg Chopped Strand Fiberglass Reinforced Raw Materials Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords