Raw Materials for Wear-Resistant Silicon Carbide Refractory Mortar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

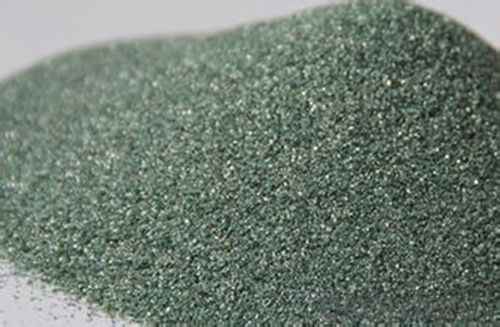

| Place of Origin: | Jiangsu, China (Mainland) | Shape: | Powder | Material: | Castable |

| SiO2 Content (%): | / | Al2O3 Content (%): | 78% | MgO Content (%): | / |

| CaO Content (%): | / | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | / |

| SiC Content (%): | / | Model Number: | CA-10 | Brand Name: | CNBM |

| Name: | silicon carbide | Volume density: | 2.8-3.0 g/cm³ | Compressive strength: | 90 Mpa |

| Apparent porosity: | 20 % | Linear change on reheating: | 0.02% | Highest using temperature: | 1600 ℃ |

| Abrasion resistance: | 7 CC |

Packaging & Delivery

| Packaging Details: | container,ton-bag,and others could be discussed |

| Delivery Detail: | 3 Days upon order confirmed |

Product Description

wear-resistant silicon carbide refractory mortar

This refractory material can be made into abrasive refractory brick for circulating fluidized bed (CFB) and waste incineration. Our products enjoy excellent thermal shock resistivity and abrasion performance with small expansion coefficient.

Advantages:

1.Good wear resistance

2.High compressive strength

3.Good flexural strength

Specifications:

Business philosophy:

Since our establishment, we have persisted in the business tent of “Winning the customers with sincerity and creating the driving force with science and technology”. We always stick to scientific and technological innovation combined all forces with sincere enthusiasm, rigorous scientific attitude and pragmatic work style. Besides, we also take a sense of mission to give a new meaning of the traditional refractory and the furnace engineering , explain the meaning of environment protection and energy saving.

During the past years, our NO.1 priority has always been customer service and customer satisfaction. We pursue honesty, pay attention to creating the products with good quality. The society is progressing; times are changing, providing first-class products is our aim. As a result, we are famous for our superior quality, competitive prices, first-class craftworks and perfect services. Therefore we can fully satisfy your demands and have a large customer base.

- Q: what's the application of fireproofing abs materials?

- fireproofing abs material is quite good, its fireproofing ability is quite good, now it's sales in the market is very well, you can purchase as you want.

- Q: Who knows about roof fireproofing materials?

- Roof water proofing materials: synthetic polymer waterproof rolls, high polymer modified asphalt waterproof coiled material, sheet metal, synthetic polymer waterproof coating, one-component water curing polyurethane waterproof coating, penetration crystalline waterproof coating. Secondly, we have to choose materials that are suitable for roof water proofing. The right waterproof materials have better waterproof performance, TS-3B one-component water curing polyurethane waterproof coating is very suitable and the performance is good. Since traditional roof waterproofing materials have requirements on the moisture content of the formation level which should be less than 9%. It is really important to choose which materials to repair leaking roofs. Kitchens and toilets are moisture, the formation levels of buildings are hard to satisfy requirements, thus, waterproof?layer and formation level are easily get separated and are ineffective in waterproofing.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Strictly speaking, as long as there are solid wood packaging, you need to do fumigation inspection, proved not necessarily used, there are IPPC chapters on it.

- Q: Can anyone say something about the curtain wall fire-proof material key sealing point?

- Keypoints; 1, curtain wall design must consider the safety requirements, one of which is fire protection design. 2, Generally, fire protection planning between curtain walls should use the method of setting fireproof isolation layer. 3, Two layers of fireproof isolation layer whose thickness should not be less than 100mm respectively on the top edge and lower edge of the material parts of the house. 4, the fireproof isolation layer commonly uses 1.5mm thick galvanized steel sheet as supporting plate, using for shelving fireproof sheet. The 100mm thick cavity between the layers is filled with mineral wool non-combustible materials tightly covered with tinfoil on the surfaces. 5, protective isolation layer should try to reconcile curtain wall beam level and finish floor level, so as to fill non-combustible material and to avoid that a piece of glass acrosses two fire?compartments. 6, the beam should be inside 100mm thick fireproof isolation layer to protect the beam and the upper curtain wall plate. 7, when there are open fire function areas like large-scale hotel or restaurant kitchen inside the curtain walls, curtain wall glass in these parts should consider using cesium potassium fireproof glass to improve the fireproof rating in the region. 8, Fireproof setting in the around areas of curtain wall can use the same method of the above fireproof setting between layers. The joint parts of fireproof isolaton layer and main part as well as curtain wall should use fireproof sealant to seal.

- Q: What refractory material does cupola lining use?

- Refractories for ehongtianlu, Yong, eajliao, najhuo cupola, refractory (refraetoriesfo:Cupola, furnace) masonry cupola and related parts. The utility model also discloses a heating furnace, which is a thermal equipment for melting pig iron in the casting industry and certain steel smelting plants. The working temperature of the guard is usually 1400 ~1 stone.. C.

- Q: Which schools are the best schools in the world for learning knowledge about refractories?

- Wish it helps you out.

- Q: What are the common refractory insulation cotton material?

- Fire resistant thermal insulation material mainly refers to inorganic thermal insulation material and compround thermal insulation material. According to the shape can be divided into: Fibrous finishes, slag wool, rock wool, glass wool, aluminum silicate cotton. ceramic fiber, micro pile of diatomite, calcium silicate, expanded perlite, expanded vermiculite, aerated concrete etc., foam like bubble glass, volcanic ash glass, foam clay, foaming concrete, paste powder polystyrene particles insulation slurry Their common characteristics is fire resistant, applicable for buildings that have high requirement for fire resisitance level. Calcium silicate, aluminum silicate, asbestos, etc. can also be used for thermal insulation of high temperature heat transfer pipe. I hope my answer can help you

- Q: What is the the best matching ratio of refractory cement?

- The best matching ratio of refractory cement is 30%. Refractory cement is also known as aluminate cement. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement. Aluminate cement is often yellow or brown or gray. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc. It is a special cement. I hope my answer will be helpful to you.

- Q: Can anyone tell me what is the material of which the mould for refractory is made?

- W18Cr4V die steel

Send your message to us

Raw Materials for Wear-Resistant Silicon Carbide Refractory Mortar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords