Carrier Air Conditioner Aluminum Coil - PVDF Painted Aluminium Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PVDF Painted Aluminium in Coil Form With Best Quality Description

PVDF Painted Aluminium in Coil Form With Best Quality is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of PVDF Painted Aluminium in Coil Form With Best Quality

PVDF Painted Aluminium in Coil Form With Best Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

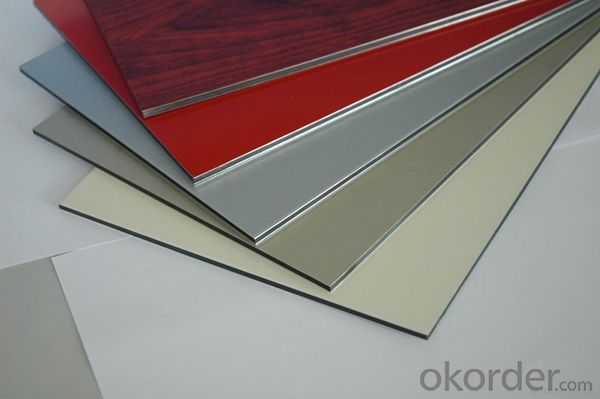

3. Application of PVDF Painted Aluminium in Coil Form With Best Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of PVDF Painted Aluminium in Coil Form With Best Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of PVDF Painted Aluminium in Coil Form With Best Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

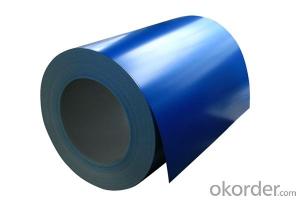

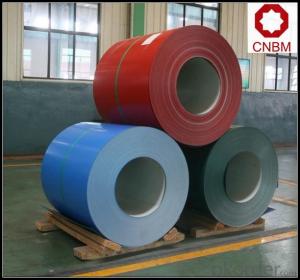

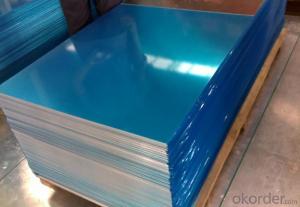

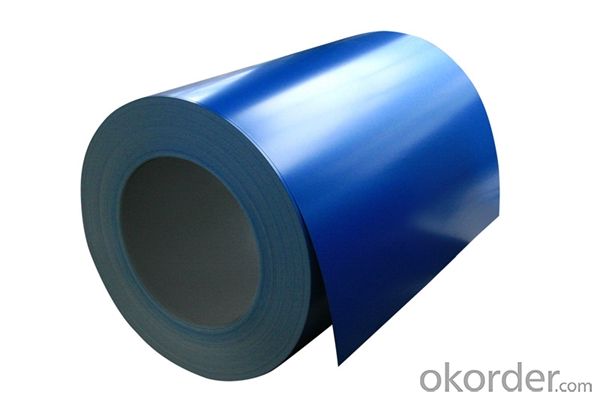

6. Image of PVDF Painted Aluminium in Coil Form With Best Quality

7. Package and shipping of PVDF Painted Aluminium in Coil Form With Best Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the thermal conductivity properties of aluminum coils?

- Aluminum coils have excellent thermal conductivity properties. Aluminum is known for its high thermal conductivity, meaning it can effectively transfer heat. This makes aluminum coils ideal for applications that require efficient heat transfer, such as in air conditioning and refrigeration systems. The thermal conductivity of aluminum coils allows for quick and effective cooling or heating, resulting in energy efficiency and enhanced performance. Additionally, aluminum's good thermal conductivity ensures that heat is evenly distributed across the coil, preventing hotspots and ensuring uniform temperature distribution. Overall, the thermal conductivity properties of aluminum coils make them a preferred choice for various heat transfer applications.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a common material choice for evaporator coils in refrigeration systems due to its excellent heat transfer properties, corrosion resistance, and lightweight nature.

- Q: This question asks about the potential health impacts of aluminum coils, which are commonly used in various industries and products.

- <p>Aluminum coils themselves are generally considered safe and do not directly affect health when used in their typical applications such as construction, electrical components, or food packaging. However, there is ongoing debate about the potential health risks of aluminum exposure, particularly when ingested. Some studies suggest a link between aluminum and neurological disorders like Alzheimer's disease, though this is not conclusively proven. It's important to note that aluminum is a common element found naturally in the environment, and the human body can naturally excrete small amounts. The use of aluminum coils in food packaging is regulated to ensure safety, and the risk of aluminum toxicity from these sources is considered low.</p>

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum is a versatile and widely-used material in various industries, including electronics. Aluminum coils are often used in the construction of transformers, inductors, and other components of electronic devices. One of the main advantages of using aluminum coils in electronic devices is their lightweight nature. Aluminum is much lighter than other commonly used materials like copper, which makes it easier to handle and transport. Additionally, aluminum has good thermal conductivity, allowing for efficient heat dissipation within electronic devices. Furthermore, aluminum coils are resistant to corrosion, which is crucial in electronic applications where the devices may be exposed to moisture or other harsh environments. This corrosion resistance helps to prolong the lifespan of the electronic device and ensures its reliability. Moreover, aluminum coils can be easily formed into various shapes and sizes, making them suitable for different electronic device designs. They can be customized to meet specific requirements, such as fitting into compact spaces or achieving specific electrical characteristics. Overall, aluminum coils offer several advantages in the manufacturing of electronic devices, including their lightweight nature, good thermal conductivity, corrosion resistance, and flexibility in design.

- Q: Hey! I have an Aluminum MacBook (2.4 GHz Core 2 Duo, 9400m graphics processor), and I'm wondering whether it's worth updating to the new 2011 13 MacBook Pro. I'm mainly looking for two things: 1. What would be the difference between the 2.4 GHz Core 2 Duo, and the 2.3 GHz i5, and 2. What would be the difference between the 9400m and the HD 3000 Graphics?Thanks! :)

- The macpro is the better machine, but for most people the difference would be negligible. your aluminum is still MORE than good enough for almost all people. What are you using it for? If you're into CAD, by all means upgrade. But if you're just surfing the net, save your money. HD3000 is actually worse graphics, but the rest of the machine is better EDIT: AGAIN, it depends on what you are using it for!!! Despite using additional details, you never once discussed how it is to be used. If you read the post, it says, for most people the difference would be negligible. IF your needs are resource intensive, you might need to replace it. If your needs are not resource intensive, you can save your money. For example, I don't need to buy a new car every year, I usually make it last 5-6 years. But my computing requirements are high enough where I replace my laptops every two years and desktops alternating years so I always have a machine that is less than a year old. MOST people squeeze 4 or more years out of a computer. If you are a general ed, humanities or undeclared your aluminum would suit you just fine thgouh your lower 2 years even though it is older. You could then get a new computer for your upper division. If you were a engineering or architecture student, I'd upgrade after first year courses, If you're in business or engineering, get a PC, if you're in architecture, journalism, music or design get a mac. Any other major, it really doesn't matter. Good luck in school!

- Q: This question asks for methods to take care of and preserve aluminum coils, ensuring their longevity and functionality.

- <p>To maintain aluminum coils, follow these steps: Keep them clean by wiping off any dust or debris. Store them in a dry environment to prevent corrosion. Avoid stacking heavy objects on top to prevent deformation. Regularly inspect for any signs of damage or wear. Use appropriate handling equipment to avoid scratches or dents. Apply a protective coating if exposed to harsh conditions. Ensure proper ventilation during storage to prevent condensation. By following these practices, you can prolong the life and maintain the quality of aluminum coils.</p>

- Q: Aluminum coil area, with aluminum sheet area, how is not the same?

- Direct measurement length and width calculation area of aluminium plate;The aluminum coil can measure the volume of the aluminum coil and then calculate the area by dividing the thickness. You can also measure the mean diameter, calculate the perimeter, multiply the number of laps, the width, and calculate the area.

- Q: How are aluminum coils used in the production of gutters and downspouts?

- Aluminum coils are used in the production of gutters and downspouts by being formed and shaped into the desired gutter or downspout profile. The coils are typically fed through a roll-forming machine that bends and molds the aluminum into the specific shape and size required. This process allows for the production of seamless gutters and downspouts, providing a more efficient and aesthetically pleasing solution for drainage systems.

- Q: Are aluminum coils suitable for automotive body panels?

- Yes, aluminum coils are suitable for automotive body panels. Aluminum is lightweight, which helps improve fuel efficiency and overall vehicle performance. Additionally, aluminum is highly corrosion-resistant, making it an ideal choice for automotive applications where the panels are exposed to various weather conditions. Its high strength-to-weight ratio also provides excellent durability and crash resistance. Moreover, aluminum can be easily formed and shaped, allowing for intricate and stylish designs. Overall, the use of aluminum coils for automotive body panels offers numerous advantages and is a popular choice among car manufacturers.

- Q: Hi i need to know what will happen to the impact strength of aluminum 2024 reinforced with Silicon carbide is treated to cryogenic temperature (nearly -200C). Will impact strength increase or decrease. Also will the impact strength vary with respect to the percentage of Silicon carbide.

- Aluminum 2024 doesn't have a transition temperature, it absorbs about 18n-m impact strength (via charpy tests I ran three weeks ago at my College course). This was constant between -150?C to +150°C (liquid nitrogen to a furnace). This excerpt from wiki: Cutting tools In 1982 at the Oak Ridge National Laboratories, George Wei, Terry Tiegs, and Paul Becher discovered a composite of aluminium oxide and silicon carbide whiskers. This material proved to be exceptionally strong. Development of this laboratory-produced composite to a commercial product took only three years. In 1985, the first commercial cutting tools made from this alumina and silicon carbide whisker-reinforced composite were introduced by the Advanced Composite Materials Corporation (ACMC) and Greenleaf Corporation. Leads me to believe it depends on how you mix the material in would make a difference. Silicon Carbide and aluminum make very strong tools, but would make it more brittle. The ceramic in a metallic crystal lattice (metal is a crystalline structure) would allow more voids to coalesce leading to a brittle fracture, but the initial strength would be improved because of substitution dislocations in the crystal structure (it would be more rigid, stronger, but more prone to sudden failure). Silicon carbide has low thermal expansion coefficient compared to aluminum also so when it gets really cold the aluminum would contract around the particles increasing the strength, but again, reducing ductility and causing fractures to occur more rapidly. Anyways, very interesting, you should do a bit of research on your own after this as I gave you some good places to work from (and I'm sure plenty of words to look up ;D )

Send your message to us

Carrier Air Conditioner Aluminum Coil - PVDF Painted Aluminium Coil with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords