China Lightweight Aluminum Sheets - PVDF Coating Aluminum Coils for Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

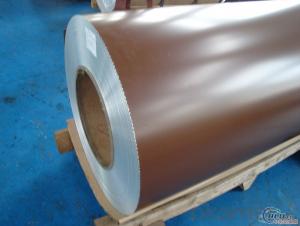

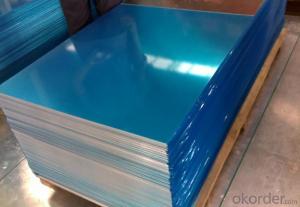

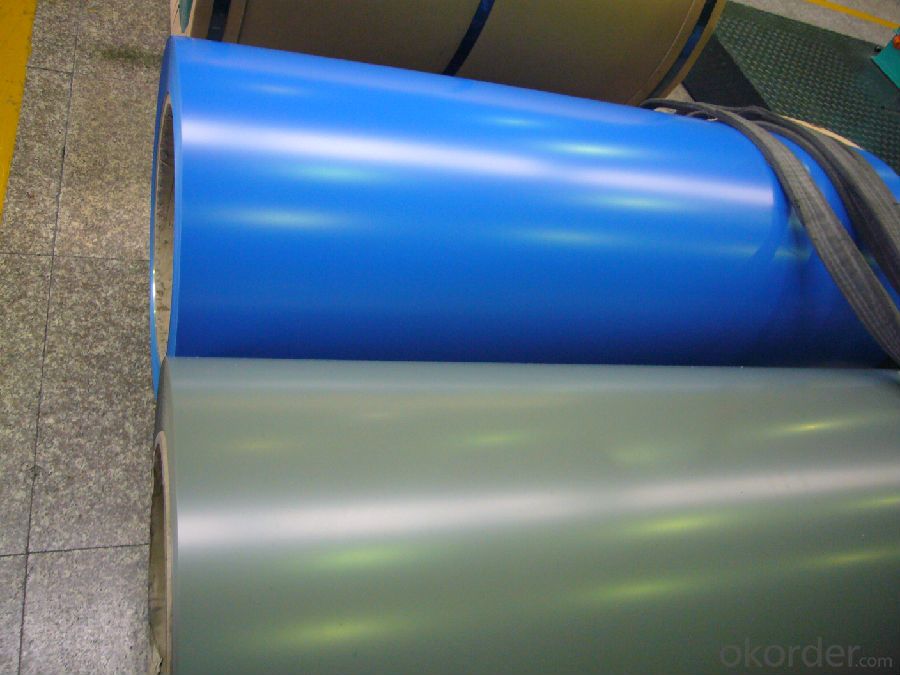

1.Structure of PVDF Coating Aluminium Coils for Wall Curtain

PVDF Coating Aluminium Coils for Wall Curtain are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of PVDF Coating Aluminium Coils for Wall Curtain

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating | Coating Thickness | Weight |

| AA1050 | H14 | Polyester | 20-25microns | about 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets varies depending on the alloy and temper. However, a commonly used value is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value represents the stiffness or rigidity of the material, indicating its ability to withstand deformation under applied stress. It is important to note that different grades and conditions of aluminum may have slightly different modulus of elasticity values, so it is recommended to consult the specific material specifications for accurate information.

- Q: Are aluminum sheets suitable for high-pressure environments?

- In high-pressure environments, aluminum sheets are generally unsuitable due to their relatively low strength-to-weight ratio compared to other materials. Consequently, there is a potential for deformation or failure under high pressure, posing safety risks. Moreover, aluminum's structural integrity is further compromised in these situations due to its relatively low melting point. Therefore, materials like steel or titanium, which offer greater strength and resistance to deformation, are typically preferred in such environments.

- Q: If Aluminum can, in fact, not be sterilized I would love to know why.

- Sterilization refers to the ability to clean a surface of bacterium. Simply pouring rubbing alcohol on something sterilizes it. Aluminum can be sterilized just as good as any other metal. If it couldn't, would we ship our favorite drinks in cans of it?

- Q: How do aluminum sheets perform in terms of electrical conductivity?

- Aluminum sheets are known for their excellent electrical conductivity, ranking just below copper in terms of efficiency.

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- Some of the different surface finishes for aluminum sheets in the aerospace industry include mill finish, anodized finish, brushed finish, and painted finish. These finishes are applied to enhance the appearance, durability, corrosion resistance, and overall performance of the aluminum sheets in aerospace applications.

- Q: Explain how aluminum sheets can impact the longevity and robustness of a building's structure.

- <p>Aluminum sheets can significantly enhance the durability of a building due to their corrosion resistance, lightweight nature, and high strength-to-weight ratio. They are resistant to weathering, which protects the building from environmental damage, and they do not rust, reducing the need for maintenance and repair. Additionally, aluminum's malleability allows for the creation of various shapes and sizes, making it versatile for different architectural designs. Its recyclability also contributes to sustainability, reducing the overall environmental impact of construction.</p>

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- Cast Aluminum Pots

- Q: Can aluminum sheets be used for boat building?

- Boat building can indeed incorporate aluminum sheets. The lightweight quality, durability, and resistance to corrosion make aluminum a favored material for constructing boats. Small recreational boats, larger yachts, and even commercial vessels commonly employ aluminum sheets in their construction. These sheets offer numerous benefits, including ease of manipulation, a remarkable strength-to-weight ratio, and minimal upkeep requirements. Furthermore, aluminum boats are esteemed for their exceptional buoyancy, stability, and fuel efficiency. All in all, utilizing aluminum sheets is a suitable and dependable choice for boat building.

- Q: Can aluminum sheets be welded or joined together?

- Indeed, welding or joining together aluminum sheets is possible. Aluminum possesses excellent weldability, allowing for its fusion through diverse welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. These methods involve the application of heat to liquefy the aluminum sheets and establish a robust connection. Furthermore, mechanical fasteners like screws, rivets, or adhesive bonding can also be employed to join aluminum sheets. The selection of the welding or joining approach hinges upon the particular application and the desired result.

- Q: Are the aluminum sheets suitable for manufacturing audio speaker enclosures?

- Yes, aluminum sheets are suitable for manufacturing audio speaker enclosures. Aluminum is a lightweight and durable material that is commonly used in the production of speaker enclosures. It has excellent acoustic properties, allowing for clear and accurate sound reproduction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the speaker enclosure. Furthermore, aluminum can be easily molded and shaped into various designs, allowing for flexibility in the manufacturing process. Overall, aluminum sheets are a suitable choice for manufacturing audio speaker enclosures due to their acoustic properties, durability, and versatility.

Send your message to us

China Lightweight Aluminum Sheets - PVDF Coating Aluminum Coils for Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords