pvc corner bead

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

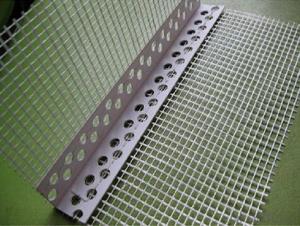

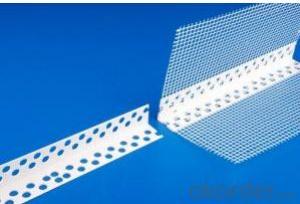

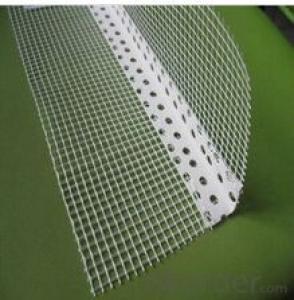

PVC drywall corner bead with mesh for wall protect

PVC corner bead with mesh reinforces exterior stucco corners with durable, straight and rust free vinyl corners. The addition of stiffener ribs and slotted nailing holes makes these products easy and quick to install level and straight.

It guides the rain dripping down along the corner line, and prevent water infiltration to the wall, as well as protect the wall from water erosion, damp, leaky, moldy.

Vinyl drywall beads with UV protector, reinforces exterior stucco corners with durable ,straight and rust free vinyl corners. The addition of stiffener ribs and slotted nailing holes makes these products

easy and quick to install level and straight.

easy and quick to install level and straight.

All type of drywall corner bead with mesh

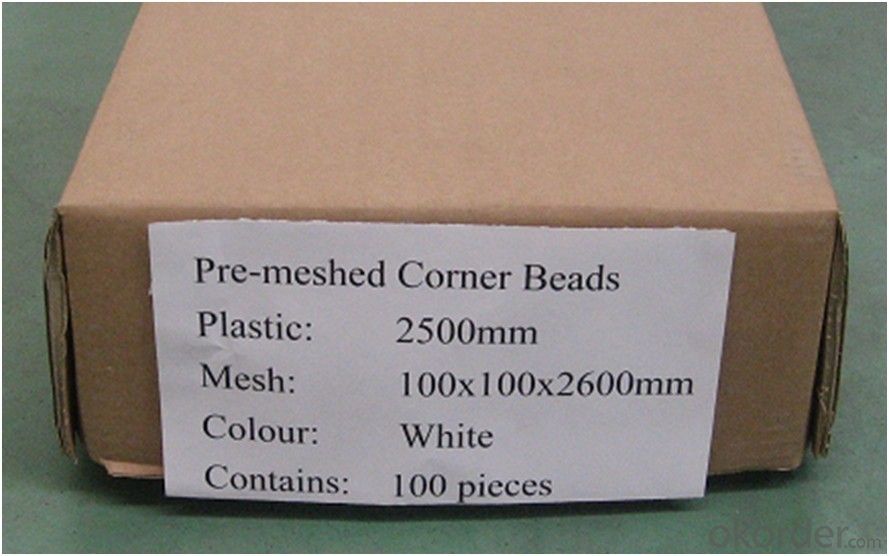

ITEM NO | Size of corner bead | Size of mesh | Color | Package |

CB01 with mesh | 23mm*23mm | 100mm*100mm | Any color | 50/100PCS per CTN |

CB23 with mesh | 23mm*23mm | 100mm*100mm | Any color | 50/100PCS per CTN |

CB2/4 with mesh | 34mm*34mm | 100mm*100mm | Any color | 50/100PCS per CTN |

CB4-TP with mesh | 34mm*34mm | 100mm*100mm | Any color | 50/100PCS per CTN |

VLT with mesh | 25mm*25mm | 100mm*100mm | Any color | 50/100PCS per CTN |

- Q: White wall white door fitted with any color of the corner of the good-looking

- Wooden plastic wall The use of environmentally friendly wood-plastic materials, surface thermal transfer treatment, no formaldehyde release. Rich realistic wood grain and imitation stone fabric effect, better decorate your home. I shop corners are solid structure, different from the market's hollow structure, more durable. And a comprehensive solution to the problem of transparent material between the corners and the walls falling into the dust.

- Q: What is the cement corner when plastering?

- Using 1: 2 cement mortar to wipe the dark corners, in order to increase the angle of the plaster layer of the hardness and strength. The height of the corner should not be less than 2m, the width of each side should not be less than 50mm.

- Q: What is the staircase angle?

- Reinforcement (Rebar) refers to reinforced concrete and prestressed reinforced concrete steel, its cross-section is round, sometimes with a rounded square. Including light round bar, ribbed steel bar, twisted steel bar. Reinforced concrete reinforcement refers to the reinforced concrete reinforcement with straight strip or strip of steel, its shape is divided into two kinds of light round bar and deformation of steel, the delivery status of straight and round disc two.

- Q: Cement angle and cement mortar skirting is a meaning, I know the baseboard is calculated by the extension of the meter, is the wall around; then the angle is how to do?

- Corner is the protection of the corner of the corner of the location of the measures not to be taken by the collision, the conventional 1: 2 cement mortar, inverted arc to corner protection, to see the Atlas, we are here to see the Southwest J, the book also More than yes

- Q: What is the corner?

- Corner is a modern packaging, mainly plastic and paper two, that is, plastic angle and paper angle, the two products are now widely used in various sectors of logistics and transportation.

- Q: What is the corner of the corner

- Refers to the room within the corner of the wall, the door side of the corners, because the place mixed mortar (or plaster gypsum mortar) plaster layer is easy to be damaged, so the use of 1: 2.5 cement mortar along the angular distance of 1.8m high, From the angle between the left and right of the 50mm range, the use of 1: 2.5 cement mortar pre-plastering to improve the plaster layer strength, the plaster is called the corner. Some industrial workshops, warehouses, garages, etc. also use angle as a corner.

- Q: Home decoration, decoration master said that the more popular is to install the wall Corner, both beautiful and protection of the corner, is it necessary for you? The price of a 200, we say what material is good? In the hope that a good is the acrylic, and relatively cheap, do not have the decoration team they are willing to do?

- Note: 1, glass fragile, easy to hurt. 2, the glass is a combination of two, the protection effect is poor. 3, angular edge whether the humanized rounded angle processing. 4, color is not beautiful, fit the home decoration. 5, is also the most important point, whether environmental protection.

- Q: Wall is a good paste or paste the good eye

- Comparison between the two, the corner of the hole than the paste a little better, but the corners of the corridor is generally better way to paste. If the punch by nails, it will damage the jade corners of the grade and beauty.

- Q: My family scraped the wall did not brush latex paint, how to dip the corner ah, now take the glass plastic stained

- You can use stone glue, this is stronger than the glass glue.

- Q: Whether the wall angle is all need corners

- Decorative corner for the decoration works in the "yang, Yin corner" construction and design, usually with a punching, it is also known as "punching". This product in the international decoration market has been widely used in indoor and outdoor corner of the construction, with the help of angle construction can not only ensure that the lines of the lines straight and beautiful, improve the construction speed, and effectively enhance the firmness of the corner, Anti-collision effect. Wood-plastic Corner "Nanning wipe a face, do not find a line", which is the construction workers on the corner of the construction of a very difficult image of the expression. The use of renovation angle to assist the construction to completely change the status quo, the corner of the construction is no longer need to rely on the ruler, the traditional cumbersome construction process has become very easy to operate, the general small workers can grasp, the same can make a perfect corner straight ; The use of angle construction can also significantly reduce the labor intensity of workers, shorten the construction time and reduce the cost of the project; high-strength profiles buried in the indoor and outdoor corners, but also play the role of ribs to improve the anti- The

Send your message to us

pvc corner bead

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords