Prime quality prepainted galvanized steel 695mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

- Q: What are the factors that affect the price of steel billets?

- There are several factors that can affect the price of steel billets. 1. Raw material costs: The cost of iron ore, coal, and other raw materials used in steel production can significantly impact the price of steel billets. Any fluctuations in these costs can directly influence the price of steel billets. 2. Demand and supply: The supply and demand dynamics of steel billets play a crucial role in determining their price. An increase in demand for steel products, such as construction materials or automotive parts, can drive up the price of steel billets. Conversely, an oversupply of steel billets can lead to a decrease in price. 3. Energy costs: The cost of energy, including electricity and fuel, required for steel production can impact the price of steel billets. Fluctuations in energy prices can affect the overall production cost and, subsequently, the price of steel billets. 4. Currency exchange rates: Steel billets are often traded on international markets, and currency exchange rates can have a significant impact on their price. If the currency of the country producing steel billets weakens against other currencies, it can make the product more affordable and potentially increase demand. 5. Trade policies and tariffs: Government regulations, trade policies, and tariffs imposed on steel billets can influence their price. Tariffs can increase the cost of imported steel billets, making domestically produced steel billets relatively more competitive and potentially leading to higher prices. 6. Economic factors: The overall state of the economy, both locally and globally, can impact the price of steel billets. During periods of economic growth, there is typically higher demand for steel products, which can drive up the price of steel billets. Conversely, during economic downturns, demand may decrease, resulting in lower prices. 7. Technological advancements: Innovations in steel production technology can impact the price of steel billets. Advancements that increase efficiency and reduce production costs can potentially lead to lower prices, while new technologies that improve the quality or properties of steel billets may command a higher price. It is important to note that these factors are interconnected and can influence each other. Therefore, understanding the complex relationship between these factors is essential in analyzing and predicting the price of steel billets.

- Q: How are steel billets used in the production of oil and gas machinery?

- The production of oil and gas machinery heavily relies on steel billets. These billets are essentially semi-finished pieces of steel that undergo further processing to produce various components needed in the oil and gas industry. To begin with, steel billets are essential in manufacturing the key structural components of oil and gas machinery, such as frames, bases, and casings. These components provide the necessary strength, stability, and support to the equipment, ensuring their safe and efficient operation even in harsh operating conditions. Furthermore, steel billets are also utilized in the production of critical rotating parts, including shafts, gears, and turbines. These components experience high loads, intense pressure, and extreme temperatures, making exceptional strength and durability a requirement. Steel billets, known for their superior mechanical properties, are an ideal material for manufacturing such parts. In addition, steel billets are employed in the production of valves, fittings, and connectors that are integral to oil and gas machinery. These components are responsible for controlling the flow of oil or gas, regulating pressure, and ensuring secure connections between various equipment and pipelines. Steel billets are chosen for these applications due to their excellent corrosion resistance, which is crucial in environments where oil and gas are present. Moreover, steel billets find application in the fabrication of heat exchangers and pressure vessels used in the oil and gas industry. Heat exchangers play a vital role in cooling or heating fluids, while pressure vessels store and transport hazardous substances safely. Steel billets are preferred for these applications due to their high thermal conductivity, excellent weldability, and resistance to extreme pressures. In summary, steel billets are extensively utilized in the production of oil and gas machinery because of their exceptional mechanical properties, corrosion resistance, and thermal conductivity. These billets provide the necessary strength, durability, and reliability to the components and equipment required in the oil and gas industry, ensuring safe and efficient operations in this critical sector.

- Q: How is the quality of steel billets ensured during production?

- The quality of steel billets is ensured during production through various measures such as regular testing and inspection. This includes conducting chemical analysis to ensure the correct composition, as well as mechanical testing to check the strength and durability of the billets. Additionally, visual inspections are carried out to identify any surface defects or imperfections. Strict quality control measures are implemented at every stage of the production process to ensure that the steel billets meet the required standards and specifications.

- Q: How can steel billets be recycled or reused?

- Steel billets can be recycled or reused in several ways. They can be melted down and used to produce new steel products, such as bars, rods, or pipes. Additionally, they can be further processed and shaped to create different steel components for various industries, including construction, automotive, and manufacturing. Furthermore, steel billets can also be repurposed for other applications, such as being used as raw material for sculptures or art installations. Overall, recycling or reusing steel billets not only helps reduce waste and conserve resources but also supports a more sustainable and circular economy.

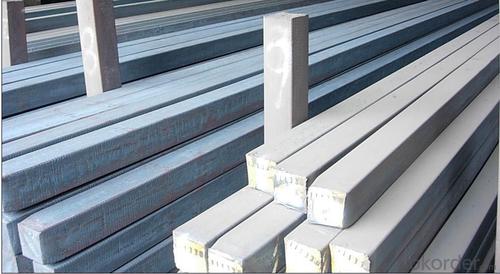

- Q: What is the typical production process for steel billets?

- The typical production process for steel billets involves several steps. First, raw materials such as iron ore, coal, and limestone are obtained. These materials are then processed and transformed into iron through a blast furnace or direct reduction process. The iron is further refined in a basic oxygen furnace or an electric arc furnace to remove impurities and adjust the composition. Once the iron is refined, it is cast into large rectangular molds known as ingots. These ingots are then heated and rolled into semi-finished products called blooms or slabs. Blooms are typically square or rectangular in shape, while slabs are flat and rectangular. The next step is to further process the blooms or slabs into billets. This is done by reheating the semi-finished products and passing them through a series of rolling mills. The rolling mills apply pressure to shape the metal and reduce its thickness. This process is known as hot rolling. After hot rolling, the billets are cooled and inspected for any defects. They may undergo additional processes such as surface treatment or heat treatment to improve their properties. The billets are then typically cut into desired lengths and stored before further processing or shipment to customers. Overall, the production process for steel billets involves obtaining raw materials, refining the iron, casting it into semi-finished products, hot rolling, and final inspection and processing. This process ensures that the steel billets meet the required specifications and quality standards before they are used for various applications in industries such as construction, automotive, and manufacturing.

- Q: What are the different types of surface defect detection methods for steel billets?

- There are various types of surface defect detection methods used for steel billets. Some of the commonly employed techniques include visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and laser scanning. 1. Visual Inspection: This is the simplest and most traditional method, where trained inspectors visually examine the surface of steel billets for any signs of defects such as cracks, scratches, or foreign material. 2. Magnetic Particle Inspection (MPI): MPI is a non-destructive testing method that uses magnetic fields and iron particles to detect surface defects. The billet is magnetized, and iron particles are applied to the surface. Any defect causes a leakage of magnetic flux, attracting the iron particles and forming visible indications. 3. Ultrasonic Testing (UT): UT involves the use of high-frequency sound waves to detect internal and surface defects in steel billets. A transducer emits ultrasonic waves into the billet, and the reflected waves are analyzed to identify any flaws or irregularities. 4. Eddy Current Testing (ECT): ECT utilizes electromagnetic induction to detect surface defects. A coil carrying an alternating current is placed near the billet's surface, which generates eddy currents. Any variation in the surface, like cracks or corrosion, alters the eddy currents, and this change is detected by the instrument. 5. Laser Scanning: Laser scanning is a relatively advanced method that uses laser technology to scan the surface of steel billets. The laser beam reflects off the surface, and a sensor analyzes the reflected light to identify any surface defects, such as scratches or dents. These different methods vary in terms of their sensitivity, speed, and cost-effectiveness. The choice of the appropriate surface defect detection method depends on factors such as the required level of accuracy, the type of defects to be detected, and the specific industry requirements.

- Q: How are steel billets used in the manufacturing of automotive parts?

- Steel billets are used in the manufacturing of automotive parts by being heated and shaped into various forms such as rods, bars, and sheets. These billets serve as the raw material for forging, casting, and machining processes, enabling the production of critical components like engine blocks, crankshafts, suspension systems, and chassis. The high strength and durability of steel make it an ideal choice for automotive applications, ensuring the safety and performance of vehicles.

- Q: How are steel billets used in the manufacturing of construction scaffolding?

- The manufacturing of construction scaffolding relies heavily on steel billets, which are an indispensable raw material. Initially, the billets are heated and then passed through rolling mills to achieve the desired shape and size for scaffolding components. Once the steel billets have been rolled to the required shape, they undergo further processing to create different scaffolding parts such as tubes, couplers, frames, and planks. These parts are then assembled together to form the scaffolding structure, which provides a secure and stable platform for workers during construction projects at elevated heights. There are several advantages to using steel billets in the manufacturing of construction scaffolding. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for scaffolding. Additionally, it is resistant to corrosion and capable of withstanding harsh weather conditions, ensuring the scaffolding remains reliable and safe throughout the construction process. Furthermore, steel scaffolding is highly versatile and can be easily customized to meet various project requirements. By using steel billets, manufacturers can create scaffolding components of different sizes, shapes, and configurations to accommodate diverse construction needs. In conclusion, steel billets play a crucial role in the manufacturing of construction scaffolding. By utilizing these raw materials, scaffolding manufacturers can produce scaffolding structures that are durable, reliable, and customizable, ultimately enhancing safety and efficiency on construction sites.

- Q: What are the potential applications of steel billets in the defense sector?

- Steel billets have several potential applications in the defense sector due to their strength, durability, and versatility. Here are a few potential applications: 1. Armored Vehicles: Steel billets can be used to manufacture the hulls and components of armored vehicles, providing enhanced protection against ballistic threats and explosive devices. The high strength and toughness of steel billets make them suitable for withstanding extreme conditions and impacts on the battlefield. 2. Weapon Systems: Steel billets can be utilized in the production of various weapon systems, such as artillery guns, tanks, and missile launchers. These components require materials that can withstand high pressures, heat, and mechanical stresses, which steel billets can provide. 3. Defense Infrastructure: Steel billets can be employed in the construction of defense infrastructure, including military bases, bunkers, and fortifications. Their high strength and resistance to corrosion make them suitable for withstanding environmental and physical challenges. 4. Naval Applications: Steel billets are crucial in the manufacturing of naval vessels, such as submarines, destroyers, and aircraft carriers. The ability of steel billets to withstand the harsh conditions of the marine environment, including corrosion and pressure, makes them an ideal choice for constructing these vessels. 5. Personal Protective Equipment (PPE): Steel billets can be used to produce body armor, helmets, and other protective gear for military personnel. The exceptional strength and impact resistance of steel billets offer enhanced protection against bullets, shrapnel, and other potential threats on the battlefield. 6. Military Infrastructure: Steel billets can be utilized in the construction of bridges, runways, and other critical military infrastructure. Their high load-bearing capacity and durability ensure the longevity and reliability of these structures, thereby supporting military operations. Overall, the potential applications of steel billets in the defense sector are diverse and crucial for enhancing the safety, efficiency, and effectiveness of defense forces. Their properties make them an invaluable material for various defense applications, ensuring the protection of personnel, equipment, and infrastructure in challenging operational environments.

- Q: What are the potential safety risks associated with handling steel billets?

- Handling steel billets can pose several potential safety risks. First and foremost, the weight of steel billets can be substantial, and improper lifting or carrying techniques can lead to musculoskeletal injuries such as strains and sprains. It is important to use proper lifting equipment and techniques to minimize the risk of these injuries. Another potential safety risk is the sharp edges and corners of steel billets. If not handled carefully, these edges can cause lacerations or puncture wounds. Wearing appropriate personal protective equipment, such as cut-resistant gloves, can help mitigate this risk. Steel billets may also be hot when they are being handled, especially if they have recently been processed or manufactured. Contact with hot billets can result in burns or thermal injuries. It is crucial to use heat-resistant gloves or other protective measures when handling hot steel billets. Additionally, steel billets are often transported using heavy machinery such as cranes or forklifts. Operating these machines without proper training or supervision can lead to accidents, including collisions, falling objects, or overturning of equipment. Adequate training, following safety protocols, and maintaining clear communication are essential to minimize these risks. Finally, steel billets may contain various chemical coatings or residues, which can be hazardous if ingested, inhaled, or come into contact with the skin. It is important to be aware of any potential hazardous substances present on the billets and take appropriate precautions, such as wearing protective clothing, gloves, and respiratory equipment if necessary. Overall, the potential safety risks associated with handling steel billets include musculoskeletal injuries, lacerations or puncture wounds, burns or thermal injuries, accidents involving heavy machinery, and exposure to hazardous substances. Following proper safety procedures, using appropriate protective equipment, and receiving comprehensive training can help mitigate these risks and ensure a safe working environment.

Send your message to us

Prime quality prepainted galvanized steel 695mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords