Prime Galvanized Pipe full sizes for greenhouse frames/handrails

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Prime Galvanized Pipe full sizes for greenhouse frames/handrails:

The galvanized pipes are used as

Scaffolding pipe, Structure pipe, Fence/Door pipe, Furniture, Low pressure fluid pipe for

water oil or gas, Boiler pipe

Applicable for greenhouse, building, fences construction, and transferring water .

2、Main Features of Prime Galvanized Pipe full sizes for greenhouse frames/handrails:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Prime Galvanized Pipe full sizes for greenhouse frames/handrails Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

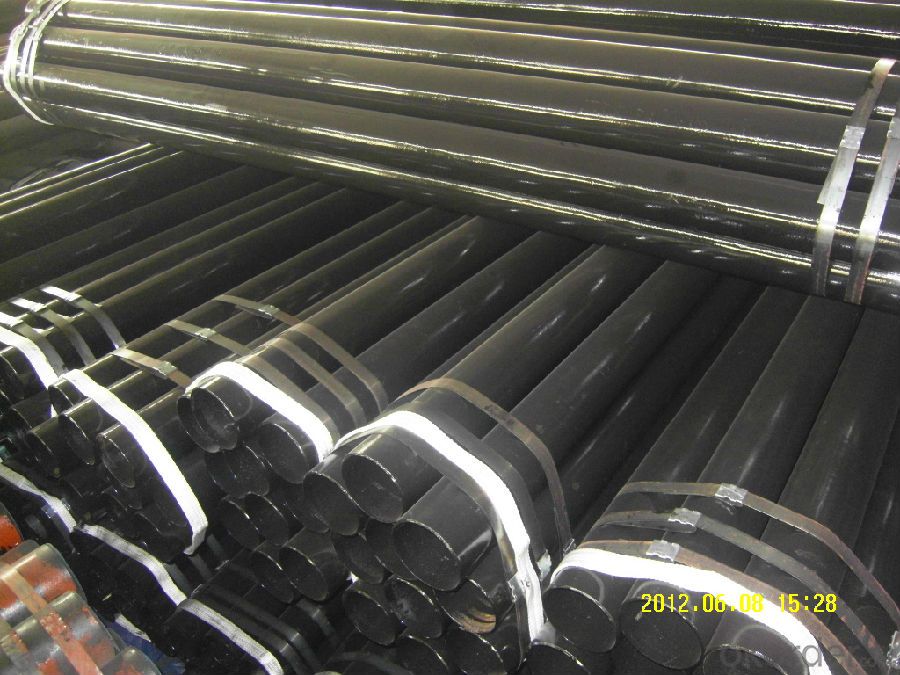

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Prime Galvanized Pipe full sizes for greenhouse frames/handrails :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Prime Galvanized Pipe full sizes for greenhouse frames/handrails images:

- Q: How are steel pipes insulated for thermal applications?

- Steel pipes are commonly insulated for thermal applications using various materials such as fiberglass, mineral wool, or foam insulation. These insulating materials are typically wrapped around the steel pipes to create a protective barrier that reduces heat transfer. Additionally, a vapor barrier may be installed to prevent moisture condensation. This insulation helps to maintain the desired temperature of the fluid or gas being transported through the pipes and prevents energy loss.

- Q: How are steel pipes classified based on their schedule?

- Steel pipes are classified based on their schedule, which refers to the wall thickness of the pipe. The schedule classification system includes different numbers such as 5, 10, 40, 80, etc., which indicate the thickness and strength of the steel pipe.

- Q: Can steel pipes be used for geothermal heating systems?

- Yes, steel pipes can be used for geothermal heating systems. Steel is a commonly used material in geothermal installations due to its durability, corrosion resistance, and ability to withstand high temperatures. It provides a reliable and long-lasting solution for transferring heat in geothermal heating systems.

- Q: What is the maximum allowable deflection for steel pipes?

- The maximum allowable deflection for steel pipes is typically determined by industry standards and design codes. These standards and codes specify the acceptable limits of deflection to ensure the structural integrity and functionality of the pipes. The maximum allowable deflection varies depending on various factors such as the pipe diameter, wall thickness, material properties, and the type of application. It is important to consult the relevant standards and codes, such as the American Society of Mechanical Engineers (ASME) B31.3 code for process piping or the American Water Works Association (AWWA) standards for water transmission and distribution pipes, to determine the specific maximum allowable deflection for a particular steel pipe application. Following these guidelines helps to ensure the safe and efficient operation of steel pipes in various industries and applications.

- Q: How are steel pipes used in water treatment plants?

- Steel pipes are commonly used in water treatment plants to transport and distribute water throughout the facility. They are used for various purposes such as conveying raw water from the source to the treatment plant, transporting treated water to storage tanks or distribution points, and carrying chemicals or additives used in the treatment process. Steel pipes are preferred due to their durability, strength, and resistance to corrosion, ensuring the safe and efficient flow of water within the plant.

- Q: How are steel pipes used in fire protection systems?

- Steel pipes are commonly used in fire protection systems because of their durability and resistance to high temperatures. They are used to transport water or other fire suppressants to sprinkler heads or fire hydrants, ensuring quick and efficient extinguishing of fires. The strength of steel pipes also allows them to withstand the pressure and force of water flow, making them a reliable choice for fire protection systems.

- Q: Is the diameter of the steel tube indicated by the outer diameter by the wall thickness or by the inside diameter by the wall thickness?

- 1, DN refers to the nominal diameter of the pipe, the outer diameter and diameter of the average. The value of DN, the value of =De, the thickness of -0.5* tube wall. Note: This is neither outer diameter nor inner diameter. Water and gas transmission pipe (galvanized steel pipe or non galvanized steel pipe), cast iron pipe, steel plastic composite pipe and polyvinyl chloride (PVC) pipe, etc., shall be marked with nominal diameter "DN" (such as DN15, DN50).2, De mainly refers to the pipe diameter, PPR, PE, PP pipe diameter, generally use the De label, are marked as outer diameter and thickness of the form, De25 * 3.3 and D generally refer to the inner diameter of the pipe.4, d concrete pipe diameter. Reinforced concrete (or concrete) pipe, clay pipe, acid resistant ceramic tube, pipe and other pipe diameter gangwa, should be said with inner diameter of D (such as D230, D380 etc.)5, Phi represents the diameter of the ordinary circle. It can also indicate the outer diameter of the pipe, but it should be multiplied by the wall thickness at this time. Such as: Phi 25 x 3, indicating outer diameter 25mm, wall thickness of 3mm pipe.

- Q: How are steel pipes used in the construction of oil and gas pipelines?

- Steel pipes are commonly used in the construction of oil and gas pipelines due to their high strength, durability, and resistance to corrosion. These pipes are employed to transport crude oil and natural gas from extraction sites to refineries and distribution centers. They provide a reliable and efficient means of transporting these valuable resources over long distances, ensuring a safe and secure supply of energy. Additionally, steel pipes are capable of withstanding high pressure and extreme temperature conditions, making them suitable for the demanding environment of oil and gas transportation.

- Q: What is the lifespan of a steel pipe?

- The lifespan of a steel pipe can vary depending on several factors such as the quality of the steel used, the conditions it is exposed to, and proper maintenance. However, on average, a well-maintained steel pipe can last anywhere from 20 to 50 years.

- Q: What is the impact resistance of steel pipes?

- The impact resistance of steel pipes is quite high due to the inherent properties of steel as a material. Steel is known for its strength and durability, which makes it able to withstand significant external forces and impacts without deforming or breaking. The impact resistance of steel pipes is further enhanced by their construction and design. Steel pipes are typically made using various manufacturing techniques such as seamless or welded construction, which ensures uniformity and strength throughout the pipe structure. This construction process eliminates weak points or seams that could compromise the impact resistance of the pipe. Moreover, steel pipes can be engineered to meet specific requirements for impact resistance based on the intended application. Different grades and types of steel can be used to achieve varying levels of impact resistance, allowing for customization to suit different industries and environments. The high impact resistance of steel pipes is particularly advantageous in industries such as construction, oil and gas, and transportation, where pipes are subjected to heavy loads, pressure, and potential impacts. Steel pipes can withstand these conditions, making them a reliable choice for various applications. In summary, the impact resistance of steel pipes is excellent due to the inherent strength and durability of steel as a material, as well as the construction techniques used in their manufacturing. Steel pipes can withstand significant external forces and impacts, making them a reliable and robust choice for a wide range of industries and applications.

Send your message to us

Prime Galvanized Pipe full sizes for greenhouse frames/handrails

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords