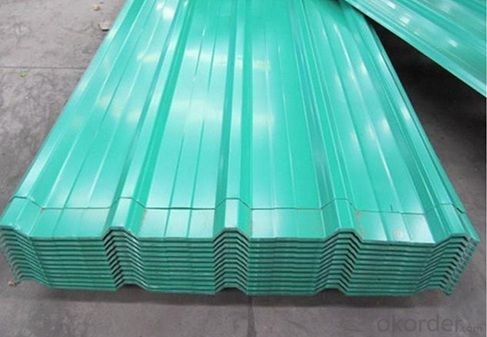

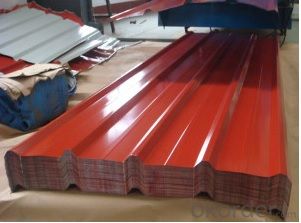

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: How does the disc shear deal with the problem of side clips into the strip?

- The disc shearing machine is a production line made up of uncoiling, feeding, shearing and coiling

- Q: How are steel strips used in the aerospace aftermarket?

- Steel strips are commonly used in the aerospace aftermarket for various purposes, such as repairing or reinforcing aircraft components, manufacturing new parts, and conducting maintenance activities. These strips are often utilized to strengthen structures, seal joints, or fasten components together. Additionally, they can be used for forming brackets, support beams, or other specialized parts required for aircraft maintenance and repairs.

- Q: How are steel strips used in the manufacturing of sporting goods?

- Steel strips are used in the manufacturing of sporting goods in various ways. They can be used as a core material for reinforcing and strengthening equipment such as tennis rackets, golf clubs, and hockey sticks. Steel strips are also utilized in the construction of frames for bicycles and exercise equipment, providing durability and stability. Additionally, they can be used in the production of springs and fasteners for sporting goods, ensuring secure and reliable performance.

- Q: How do steel strips compare to other metal strips?

- Steel strips are known for their superior strength and durability compared to other metal strips. They have a higher tensile strength, which allows them to withstand heavy loads and resist deformation. Additionally, steel strips offer excellent corrosion resistance and can be easily formed into various shapes and sizes.

- Q: How are steel strips used in the production of consumer electronics?

- Steel strips are commonly used in the production of consumer electronics in several different ways. Firstly, steel strips are often used as a component in the manufacturing of electronic device casings or housings. The strips are formed into specific shapes and sizes to create the outer shell of the device, providing a sturdy and durable structure to protect the internal components. Additionally, steel strips are used in the production of brackets, frames, and other structural components within consumer electronics. These strips are often cut, shaped, and welded to create various supports and reinforcements that help to secure and stabilize different parts of the electronic device. Furthermore, steel strips can be utilized in the production of connectors and electrical contacts. These strips are often precision-cut and treated to ensure proper conductivity and durability. They are then used to establish electrical connections within the device, enabling the flow of current between different components. Overall, steel strips play a crucial role in the production of consumer electronics by providing strength, durability, and functionality to the final product. Their versatility and ability to be formed into various shapes make them a valuable material in the manufacturing process, ensuring the reliability and longevity of electronic devices.

- Q: Are steel strips available in different finishes?

- Yes, steel strips are available in different finishes.

- Q: What are the different surface coatings available for steel strips to improve wear resistance?

- There are several surface coatings available for steel strips to enhance their wear resistance. Some common options include metallic coatings like zinc or tin, ceramic coatings such as alumina or zirconia, and organic coatings like polymer-based materials. These coatings form a protective layer on the steel surface, reducing friction and preventing wear and corrosion. The choice of coating depends on the specific application requirements and the level of wear resistance needed.

- Q: How do steel strips contribute to weight reduction in various applications?

- Steel strips contribute to weight reduction in various applications by being lightweight yet strong. They provide a high strength-to-weight ratio, allowing manufacturers to use thinner and lighter steel strips without sacrificing structural integrity or performance. This reduction in weight can lead to improved fuel efficiency in transportation, increased payload capacity in aerospace, and overall cost savings in various industries.

- Q: How are steel strips packaged for shipping?

- Steel strips are typically packaged for shipping by being tightly wound around a core or spool, secured with strapping or bands to prevent unraveling, and then wrapped in protective materials such as plastic or paper to shield them from moisture and damage during transportation.

- Q: What is the purpose of hardening and tempering steel strips?

- The purpose behind the hardening and tempering of steel strips is to enhance their mechanical properties and enhance their overall performance in various applications. To harden steel strips, they are heated to a specific temperature called the critical temperature and then rapidly cooled by quenching them in oil, water, or air. This rapid cooling process transforms the crystalline structure of the steel, resulting in a material that is harder and stronger. Hardened steel strips are highly resistant to deformation, wear, and abrasion, making them ideal for applications that require high strength and durability, such as cutting tools, springs, and machine components. However, the downside of hardened steel strips is that they can become brittle and prone to cracking. This is where tempering comes into play. Tempering involves reheating the hardened steel strips to a lower temperature and then cooling them slowly. This controlled heating and cooling process allows for the adjustment of the steel's hardness and toughness, finding a balance between strength and its ability to withstand impacts and shocks. By hardening and tempering steel strips, manufacturers can customize the material's properties to meet specific requirements. This allows the steel to possess a combination of hardness, strength, toughness, and flexibility that is suitable for a wide range of applications. Furthermore, hardening and tempering can also enhance the steel's resistance to corrosion and extend its service life.

Send your message to us

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords