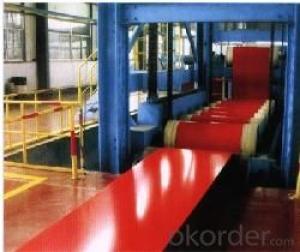

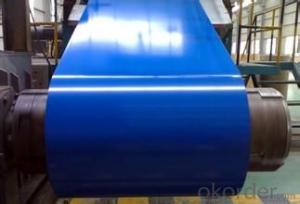

Prepainted steel coils Hot sale Chinese supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,JIS | Grade: | steel | Thickness: | 0.17-1.5mm |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | SGCC Q195L, Q235, DX51D |

| Type: | Steel Coil | Technique: | Hot Rolled,hot dip | Surface Treatment: | Coated |

| Application: | Flange Plate | Special Use: | Steel | Width: | 600-1250mm |

| Length: | 2000-6000mm |

| Commodity | Prepanited steel coil |

| Grade | JIS G3302(SGCC), DX51D, EN10142, GB/T2518-2004, ASTM 653 |

| Standard | ASTM, AISI, DIN, GB |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.16-1.2mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating | Galvanized |

| Zinc / PE coating | Z60-275g/m2 ,12-20μm(top)/7-10μm(bottom) |

| Surface | RAL System as per customers request |

| ID coil | 508mm |

| Coil weight | 4-6MT |

| Package | Properly packed for ocean freight exportation |

| Application | Industrial panels, roofing and siding for painting |

| Payment terms | 30%TT in advance+70% TT or irrevocable 100%L/C at sight |

| Delivery time | 25 days after recepit of 30% TT or L/C |

PACKING

4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection

FAQ

We have organized several common questions for our clients,may help you sincerely:

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

In the purchase of product within 20-25 days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 30 days can be served.

3)Do you have necessary certificate or inspection to make sure we can import smoothly?

Syringes are CE,FDA approved. And we supplied main nations in the world.

- Q: How can I judge the quality of steel?

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. There are many more scientific methods of measuring the quality of the alloy such as texture measurement technique etc are also employed. In layman’s term the quality can be measured by the hardness of surface, brightness and smoothness of the surface and absence of any depressions or troughs.

- Q: What are the different coil packaging methods used for steel coils?

- There are several coil packaging methods that are commonly used for steel coils. These methods are designed to ensure the protection and safe transportation of steel coils, as well as to optimize storage space. Some of the different coil packaging methods used for steel coils include: 1. Strapping: This method involves securing the steel coils with metal or plastic straps. Strapping provides stability and prevents the coils from unrolling or shifting during transportation. It is commonly used for smaller coils or when additional packaging methods are also employed. 2. Stretch wrapping: Stretch wrapping involves using a stretch film to tightly wrap the steel coils. This method provides excellent protection against dust, moisture, and other contaminants. It also helps to keep the coils tightly bound together and prevents them from moving during handling and transportation. 3. Steel banding: Steel banding is a method that involves using steel bands or straps to secure the coils. This packaging method provides superior strength and durability. Steel banding is commonly used for larger and heavier steel coils that require extra reinforcement. 4. Wooden crating: Wooden crates are often used for packaging steel coils that are particularly large or heavy. The coils are placed within a wooden crate, which provides enhanced protection against impacts, moisture, and other external factors. Wooden crating is typically utilized for long-distance transportation or for coils that need to be stored for extended periods. 5. Coil saddles: Coil saddles are specialized devices that are used to package steel coils. These devices are designed to securely hold the coils in place and prevent them from rolling or moving. Coil saddles are commonly used for large coils that cannot be easily strapped or wrapped. 6. Paper interleaving: Paper interleaving involves placing sheets of paper between each layer of steel coils. This method helps to prevent damage caused by friction between the coils. Paper interleaving is often used for coils that have a high surface finish or are susceptible to scratching. Each of these coil packaging methods offers distinct advantages and is chosen based on factors such as the size and weight of the steel coils, transportation requirements, and the desired level of protection. By employing these packaging methods, steel coil manufacturers and distributors can ensure that their products arrive safely and in optimal condition at their destination.

- Q: What are the common challenges faced in steel coil production?

- Some common challenges faced in steel coil production include ensuring consistent quality and thickness of the coil, maintaining efficient production rates, managing inventory and storage of coils, addressing issues related to coil surface defects and handling, and adhering to strict safety regulations. Additionally, fluctuations in raw material prices and market demand pose further challenges for steel coil producers.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and single-knife slitting.

- Q: If you were selecting a tool steel for an extreme impact load application, which one would you pick? why?thanks

- It all depends what the application actually is. For hammers I would select a hammer grade B1 steel. For impact loading where an edge is needed I would be going for O1 or similar (oil quenching steels tend to be a little tougher than air hardening). For mining tools a very high manganese steel (Hadfields steel) - this is not a true tool steel. The best place to start is by looking at the ranking of the properties which you want - hardness v toughness v strength - and then use this to put the steels in rank order. Price and availablity then sort the problem out for you (in the real world).

- Q: Can steel coils be custom-made to specific requirements?

- Indeed, it is possible to manufacture steel coils according to specific requirements. Steel producers possess the necessary capabilities to manufacture steel coils with diverse dimensions, thicknesses, and specifications in order to meet the specific demands of their customers. These coils can be tailored in terms of width, length, weight, and even surface finish to accommodate specific applications and industries. Furthermore, customization options may include variations in steel grade, coating type, and mechanical properties to guarantee the desired performance and functionality. The capacity to customize steel coils to meet specific requirements enables their optimal utilization in a variety of sectors, including automotive, construction, appliances, and manufacturing, among others.

- Q: What are the safety precautions when handling steel coils?

- The safety precautions when handling steel coils include wearing appropriate personal protective equipment such as gloves, safety boots, and eye protection to prevent injuries. It is important to use proper lifting techniques and equipment to avoid strains or back injuries. Coils should be stored in a stable manner to prevent them from falling or causing accidents. Additionally, workers should be trained on the proper handling procedures and be aware of their surroundings to prevent any potential hazards.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they serve as the core material for the door's structure, providing strength and durability. The coils are typically shaped, cut, and molded into the desired door shape, then combined with fire-resistant materials such as gypsum or mineral wool to enhance the door's fire resistance.

- Q: What are the different methods of blanking steel coils?

- There are several methods for blanking steel coils, including shearing, laser cutting, and waterjet cutting. Shearing involves using sharp blades to cut the coil into desired shapes. Laser cutting utilizes a high-powered laser beam to accurately cut through the steel. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive materials to cut the coil. These methods offer different levels of precision, speed, and cost-effectiveness depending on the specific requirements of the blanking process.

- Q: What are the different types of steel coil surface finish treatments?

- There are several different types of steel coil surface finish treatments, including hot-dip galvanizing, electro-galvanizing, zinc plating, powder coating, and painting. These treatments are applied to steel coils to enhance their durability, corrosion resistance, and aesthetic appeal.

Send your message to us

Prepainted steel coils Hot sale Chinese supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords