Prepainted Steel Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

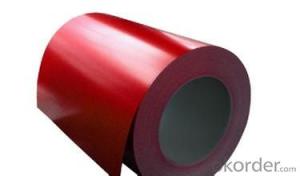

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent heat resistance performance

• High strength

• Excellent corrosion resistance • Capability of decoration, molding, corrosion resistance • Workability, durability • Good formability

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

Thickness : 0.14-1.20 mm

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements.....

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

we will consider to give more discount if you make big order like 1000 tons and more.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC.

- Q: I'm getting new strings on my dad's old acoustic guitar so I can learn how to play it and I'm wondering if I should get nylon or steel strings. Are there any major differences between the two aside from the nylon strings being easier on your fingers? Like do the Nylon strings sound different?

- Listen to jwent You do NOT want to put steel strings on a nylon string guitar it will pull up the bridge, and top of the guitar, and break the plastic tuners that can't handle the extra tension You can put nylon a steel string guitar, but it won't sound like a classic guitar, because the steel string guitar has the extra bracing, to handle the tension of the steel strings, won't hurt anything, just won't sound as good If you want to soften the feel and sound of a steel string guitar, another option is silk n steel

- Q: How do steel coils contribute to the construction industry?

- Steel coils are essential in the construction industry as they are used to manufacture a wide range of structural components and materials. These coils are transformed into beams, pipes, sheets, and other forms, providing the necessary strength and durability required for construction projects. Steel coils also offer versatility, allowing for customization and adaptation to meet specific project requirements. Their contribution to the construction industry is undeniable, as steel coils form the backbone of many structures, ensuring stability, safety, and longevity.

- Q: Can steel coils be used in the manufacturing of appliances?

- Appliances can indeed utilize steel coils for their production. They are frequently employed as the principal raw material in the manufacturing of various appliances, including refrigerators, stoves, dishwashers, and washing machines. To meet appliance specifications, these steel coils are typically processed and molded into specific parts like panels, frames, or doors. The utilization of steel coils in appliance manufacturing provides several benefits, such as robustness, longevity, and resistance against corrosion. Moreover, steel coils can be effortlessly fabricated and manipulated to accommodate the distinct design needs of different appliances, making them a versatile and frequently employed material within the industry.

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components by being processed through various techniques such as cutting, bending, and welding to form the desired shapes and sizes. These coils serve as the raw material for fabricating beams, columns, and other structural elements used in buildings, bridges, and infrastructure projects. The high strength and durability of steel make it an ideal choice for constructing load-bearing components, ensuring the stability and integrity of the structures.

- Q: Don't ask me why, but I took my stainless steel ring and I heated it up with my gas stove. I stuck it in there til the metal turned red, and the flame which is normally blue turned orange for some reason when the metal turned red. Anyway, afterwards i cooled it off in water and now it's all discolored and it feels different. It's weighs less and it doesn't feel the same. Plus, it's ugly cause it's all black and blue. What happened? Someone help

- My fiancé got a Tungsten wedding band. It's super tough and doesn't scratch. We made sure to get an extended warranty, because those rings can't be resized and otherwise we'd have to pay for a new one. We were thinking about titanium, but it's really light and he just didn't like the feel of it. The tungsten was heavy and felt durable and manly. He also loves the color, it's darker than silver so it looks non traditional. Make sure to get a ring with a curved band for comfort, or he may not like wearing it. Platinum actually scratches easily, so don't even think of it! My fiancé's wedding band was about $250, a bit more with the warranty. Stainless steel will be cheaper, but it's not as durable or scratch resistant as tungsten.

- Q: What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, cutting, shearing, and edge rolling. Slitting involves cutting the coil into narrower strips, while cutting involves separating the coil into smaller sections. Shearing is a process of cutting the edges of the coil to remove any irregularities or defects. Edge rolling is a method that involves rolling the edges of the coil to create a smoother and more uniform finish.

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- You pay your money and take your choice. High carbon non-stainless steels are easier to sharpen and hold their cutting edge longer than stainless. Stainless steels generally are rust resistant, not rust-proof. However, there are more than 40 types of steels being used for knife-making. Probably the best in the stainless range are the American Hi-performance Stainless Steels. These are graded as; CPM440V, CPM420V, CPM10V, CPM3V and 154-CM. Incidentally, nearly all knife steels contain carbon in varying amounts. The only one that I am aware of that does not contain any carbon is Sandvic12C-27.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

- Q: does he use a nylon guitar or steel?

- He's using a nylon guitar. The trick to know whether it is nylon or steel is by looking at the headstock. steel ones use the ones you see from a regular electric guitar. the nylon ones has two major holes on them I don't know why but that's based on what i have seen. One more thing is its bridge. the nylon ones do not use pin-like stoppers to prevent the strings from falling off unlike the steel-stringed guitars that use them.

- Q: I am making a permanent magnet, just for fun. I am trying to find the best grade of steel to do so with.

- The type of steel you require is Steel ( Iron + Carbon, mainly.),{many different types of steel } with a high Cobalt and Nickel content. These alloyed together give the best Permanent Magnets, mainly due to their own individual magnetic properties / characteristics being retained in the Alloy. All 3 metals can be magnetised by there own, but Cobalt is known to cause cancer. Nickel, is poisonous and can also cause sever Dermatitis and the destruction of skin tissue.But when alloyed together with Iron they are pretty harmless. Interesting thing is, All of these metals (in this case Elements) can share the same Mass Number ( 60 ). And yet are totally different in their other properties beside Magnetism. Cobalt - Samarium - alloys, create some of the worlds most powerful permanent magnets. And were used in medicine, But are now superseded by Neodymium magnets which are employed instead. Edit; What you could try is, mild steel which is widely available and easily found. . The steels mentioned above are pretty exclusive materials and I personally would not know how to test for their contents, of which they are made from. Soft Iron is good for making electro-magnets if you fancy a go at making one. .

Send your message to us

Prepainted Steel Coil in High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords