Prepainted steel coil construction building material with galvanized color

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 33645 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prepainted steel coil construction building material with galvanized color

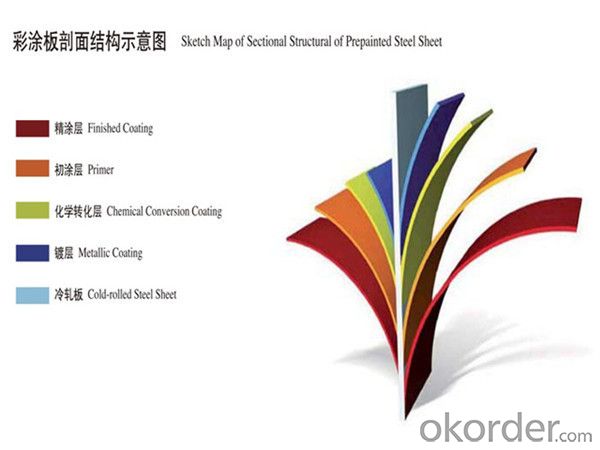

Prepainted steel sheet /coil is coated with organic layer, which provides higher anti-corrosion property and a

longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc

coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon

modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

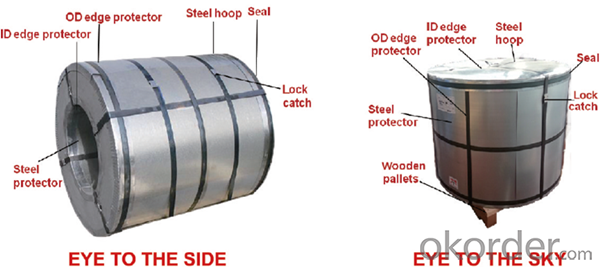

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to serve as a form of material storage and transportation for various industries. These coils are typically made by winding steel strips into a circular shape, providing a compact and efficient way to store large quantities of steel. Steel coils are used in numerous applications, such as manufacturing, construction, automotive, and appliance industries, where they can be easily transported, processed, and formed into the desired shape for different products.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- How grimy is your range? I actually have a stainless range and all I do is discover a soapy sponge on it, with dish cleansing soap. I get rid of each and all of the knobs and burners approximately as quickly as a week (and every time I fry something and splatter oil everywhere, yet i attempt to disguise issues with foil as quickly as I fry to sidestep a multitude). It takes possibly 5 minutes to scrub my range because I shop it clean and not in any respect, ever use it if it has spills on it. i've got found out via the years to wipe issues up right now, or the spills get baked on and become very confusing to get rid of. My range is electrical powered, so I take off the electrical powered burners and gently wash those with a soapy sponge too (I carry them and rub the soapy sponge on them, then carry them below the faucet to rinse, without getting the plug in factor section moist). My range continues to be very clean this way, and that i take advantage of the rougher side of a non-scratch sponge for something that desires some scrubbing. in the experience that your range has undesirable stains caught on it, you ought to use very, very advantageous metallic wool on it. An SOS pad will paintings, do in basic terms no longer rub too problematic or you will take off the shine from the range. SOS pads are ok on each and all of the immaculate areas of the range. whilst completed washing it, take a humid dish towel and wipe each and all of the cleansing soap off, then dry the range and it will seem large.

- Q: How are steel coils used in the manufacturing of household appliances?

- Steel coils are used in the manufacturing of household appliances as a raw material for forming various components such as panels, frames, and structures. The coils are typically cut, shaped, and welded to create the necessary parts used in appliances like refrigerators, stoves, and washing machines. The durability and strength of steel make it an ideal material for ensuring the longevity and performance of these appliances.

- Q: What are the factors affecting the corrosion resistance of steel coils?

- There are several factors that can affect the corrosion resistance of steel coils, including the composition of the steel, the presence of impurities, the environmental conditions, the coating or protective layer applied to the steel, and the presence of any physical damage or defects on the surface of the coils.

- Q: How are steel coils used in the production of HVAC ducts?

- HVAC duct production relies heavily on steel coils, which are vital for their construction. These coils, typically composed of galvanized steel, possess the qualities of strength, durability, and corrosion resistance. To create the necessary flat sheets, the steel coils undergo an initial unwinding and flattening process. These sheets are then cut into specific sizes and shapes in accordance with the design and dimensions of the HVAC ducts. Additionally, the steel coils are subjected to various machines, such as shearing, slitting, and roll forming machines, to achieve the desired shapes and sizes for the ducts. Once transformed into the appropriate shapes, the steel coils are further processed to add additional features to the ducts. This can include bending, folding, or welding processes to create bends, angles, or connections in the ductwork. These processes allow for customization, ensuring that the ducts perfectly fit the specific requirements of the HVAC system and the building structure. Moreover, steel coils play a crucial role in maintaining the strength and integrity of HVAC ducts. The galvanized steel used in the coils provides a protective layer that prevents rust and corrosion, resulting in more durable and long-lasting ducts. This is particularly significant as HVAC ducts are regularly exposed to various environmental factors such as moisture, temperature changes, and airborne contaminants. In summary, steel coils are an essential and fundamental component in the production of HVAC ducts. They not only provide the necessary strength, durability, and corrosion resistance but also offer flexibility and customization in the manufacturing process.

- Q: I'm just wondering what the best steel would be for an edc/hunting knife that could put up with alot of abuse.

- That one they use for the Army Combat Knife, I forgot what its called but Its a good one if your going to use it for camping.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- Best Wok To Buy

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- as has been said before it is a mystery steel that could mean anything honestly I am guessing closer to 1045 than the already mentioned 1095.... or just stainless steel of some variety tldr we all are telling the truth do not buy it

- Q: What are the common maintenance practices for steel coils?

- Common maintenance practices for steel coils include regularly inspecting for any signs of corrosion, cleaning the coils to remove dirt and debris, applying protective coatings or paint to prevent rust, storing the coils in a dry and well-ventilated area, and ensuring proper handling and transportation to avoid any damage. Additionally, it is important to monitor and control the humidity levels around the coils to prevent moisture buildup, which can lead to corrosion.

- Q: What are the weight ranges of steel coils?

- The weight ranges of steel coils can vary depending on their dimensions and intended use. Generally, steel coils can range from a few hundred pounds to several tons in weight. For example, hot-rolled steel coils typically weigh between 10 and 25 tons, while cold-rolled steel coils can weigh anywhere from a few hundred pounds to 20 tons. The weight of steel coils can also vary based on factors such as the thickness and width of the coil, as well as the grade and type of steel being used. Ultimately, the weight range of steel coils is determined by the specific requirements of the industry and application in which they are being used.

Send your message to us

Prepainted steel coil construction building material with galvanized color

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 33645 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords