Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

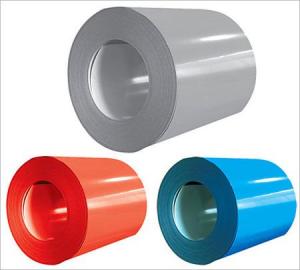

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

Zinc Coating 100-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 3-6MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Production Flow Of Prepainted Galvanized Steel

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are used in the manufacturing of building materials as they provide a strong and durable base for various products. These coils are typically unrolled and shaped into different forms, such as sheets or beams, which are then used to create structures like roofing, siding, and framing. The flexibility and strength of steel make it an ideal material for construction purposes, ensuring buildings are sturdy and long-lasting.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality of the raw material used, the thickness and width of the coil, the temperature and humidity during the manufacturing process, the tension applied during coiling, and the cooling and leveling processes employed.

- Q: What are the common methods of recoiling steel coils?

- The common methods of recoiling steel coils include slitting, rewinding, oscillating, and recoiling using a mandrel or a recoiler machine. Slitting involves cutting the wide coil into smaller widths, while rewinding involves rewinding the coil into a tighter, more compact roll. Oscillating is a method where the coil is wound back and forth to create a narrow, oscillating coil. Finally, recoiling using a mandrel or a recoiler machine involves winding the coil onto a mandrel or a spool to create a new coil of desired size and shape.

- Q: How are steel coils used in the production of industrial equipment?

- Steel coils are used in the production of industrial equipment as their versatile and durable nature makes them ideal for fabricating various components such as frames, structures, panels, and parts. These coils are processed and shaped into the required size and shape, allowing manufacturers to create sturdy and reliable equipment that can withstand heavy use and harsh environments.

- Q: How are steel coils used in the production of electrical transformers?

- Steel coils are used in the production of electrical transformers as they provide the core structure for the transformer. The steel coils are wound with insulated copper wire to create the primary and secondary windings of the transformer, which allow for the transformation of electrical energy from one voltage level to another. The steel coil helps to conduct and distribute magnetic flux within the transformer, ensuring efficient energy transfer and reducing losses.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: How are steel coils weighed?

- Steel coils are typically weighed using industrial weighing scales or load cells. The coils are lifted by cranes or forklifts and placed on the scales or load cells to determine their weight.

- Q: What are the different methods of coil flattening for steel coils?

- There are several methods used for coil flattening in the steel industry. Some of the common methods include roller leveling, tension leveling, and stretcher leveling. Roller leveling involves passing the coil through a series of rollers to flatten it. Tension leveling uses a combination of tension and bending to remove any shape defects in the coil. Stretcher leveling stretches the coil in the lengthwise direction to eliminate any waviness or buckling. Each method has its own advantages and is used based on the specific requirements of the steel coil.

- Q: which cost more: ALLOY, GUNMENTAL OR STAINLESS STEEL. GIVE ME AN IDEA OF THE COST OF EACH.

- Alloy okorder /

Send your message to us

Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords