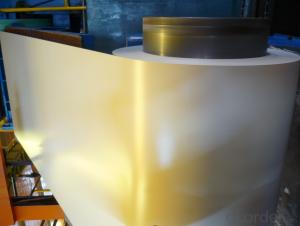

Prepainted Galvanized Steel Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATION:

Product name | Prepainted Galvanized Steel Plates |

Thickness | 0.3mm—1.2mm |

Width Length | 600mm—1250mm As client's requirement |

Zinc coating | 60g-225g |

Paint Thickness | Top:15-30um, back:5-10um |

Standard | ASTM A792, JIS G3321, JIS G3317, GB |

Material | SGCC/SGCH |

Base Plate | Hot dipped zinc coated steel sheet,hot dipped A-Z coated steel sheet |

Surface Paint | PE,PP |

Color Series | RAL color number series |

Equipment | Double coating double baking |

Packing | 1. standard seaworthy package : waterproof paper/iron sheet/steel strip/steel pallet 2. According to customers' requirements |

Coil Wgt. | 3Mt - 8Mt |

Coil ID | φ508mm,φ610mm |

Payment | T/T or L/C |

Min order | 50 tons |

Capacity | 4000Mt/week |

Delivery time | within 40 days upon receipt original L/C or advance payment |

APPLICATION:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers,

video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: Want to construct a patio cover approx. 20 feet long. Only want to use a 6x6 or 8x8 post at each end. What size steel i-beam would I have to use to carry the load???

- First of all is it a rule of thumb with carpenters and ironworkers never to set steel on wood. I would use a 14 tall (2) ply lvl header. *Laminated veneer Lumber. This will hold the weight of the structure between your posts. A steel beam would be quite costly today as prices on steel have skyrocketed, plus you would need a boom truck or small crane to set this beam, and you would need some sort of mounting bracket or holes pre-drilled in the beam ends to secure it to the posts. Plus you would need to have the beam delivered and if your patio is in the backyard - you would need another pc.of equipment to get it around back. Advice from me is to go with an LVL beam. They are 1+3/4 Thick and you would need a (2 ply ) beam, which means you set one pc. and then laminate another one into the first. Glue between layers (use heavy duty liquid nails) and then Lag screw them together. Use 5/16 x 3 lag screws with a washer on each one. Pre-drill holes about 3/16 smaller than lag screws - then insert lag screws and tighten up with an electric impact.

- Q: How are steel coils coated for specific applications?

- Steel coils are coated for specific applications through a process called coil coating. This involves applying a protective layer of paint, polymer, or other coatings onto the steel coils using methods like roll coating or spray coating. The coating is carefully selected based on the desired properties such as corrosion resistance, durability, or aesthetic appeal required for the specific application.

- Q: What temp does fire have to be to melt steel?

- more than 300° F

- Q: How are steel coils protected during shipping?

- Various measures are implemented to safeguard steel coils during shipping, guaranteeing their safety and preventing any harm. One widely used technique is the utilization of steel coil cradles or saddles. These structures, specifically designed for this purpose, securely hold the coils in place and prevent any movement or rolling during transit. Typically made from robust steel or durable materials, the cradles are engineered to withstand the weight and pressure of the coils. Additionally, steel coils are often wrapped in protective materials like plastic or paper. This wrapping acts as a barrier, shielding the coils from potential contaminants such as moisture, dust, and other detrimental factors that could compromise their quality. The wrapping is applied tightly to ensure it remains in position throughout the entire shipping process. To provide further protection, specialized equipment is used to load the coils into shipping containers or onto flatbed trucks. Coil hooks or lifting clamps are examples of such equipment, allowing for safe and secure handling, thereby minimizing the risk of accidents or damage during the loading and unloading stages. In certain cases, steel coils may be packed into wooden or metal crates to offer additional safeguarding. These crates serve as an extra layer of security and prevent any potential impacts or rough handling from causing damage to the coils. Ensuring the protection of steel coils during shipping is of utmost importance to ensure their arrival at the intended destination in optimal condition. By employing cradles, protective wrapping, specialized equipment, and additional packaging when necessary, the risk of damage is significantly reduced, resulting in a smooth and successful transportation process.

- Q: What are the different types of steel coil slitting blades?

- There are several different types of steel coil slitting blades, each designed for specific applications and materials. Some of the most common types include: 1. Circular slitting blades: These are the most commonly used blades for slitting steel coils. They are circular in shape and have a sharp edge that cuts through the coil as it rotates. Circular slitting blades can be made from various materials, such as high-speed steel or tungsten carbide, depending on the desired cutting performance and durability. 2. Arbors: Arbors are another type of steel coil slitting blade that is used in conjunction with circular slitting blades. They are cylindrical in shape and hold the circular blade in place, allowing for precise and consistent slitting of the coil. 3. Shear slitting blades: Shear slitting blades are used for cutting thicker and harder materials, such as stainless steel or aluminum. They have a straight edge and work by shearing the material apart, rather than cutting through it like circular blades. Shear slitting blades are typically made from high-quality tool steel to withstand the high forces involved in cutting thicker materials. 4. Crush cut slitting blades: Crush cut blades are used for slitting softer materials, such as paper or plastic. These blades have a blunt edge that crushes and tears the material, rather than cutting it cleanly. Crush cut blades are often made from materials like carbon steel or hardened stainless steel. 5. Razor slitting blades: Razor slitting blades are used for slitting delicate materials that require a clean and precise cut, such as thin films or foils. These blades have an extremely sharp edge that slices through the material without causing any damage or distortion. Razor slitting blades are typically made from high-quality stainless steel or tungsten carbide. It is important to select the appropriate type of steel coil slitting blade based on the specific application, material, and desired cutting performance. The choice of blade will greatly impact the quality and efficiency of the slitting process.

- Q: This EN10025 S355JR is a European code for steel, of which the properties can be found here.

- Is bether to use this one below! ASTM A588/A588M. Standard Specification for High-Strength Low-Alloy Structural Steel with 50 ksi [345 MPa] Minimum Yield Point , Weather Resistant

- Q: How do steel coils contribute to the agricultural machinery industry?

- Steel coils are an essential component in the agricultural machinery industry due to their versatile and durable nature. They are used in various applications and play a crucial role in improving the efficiency and productivity of agricultural machinery. One of the primary ways steel coils contribute to the agricultural machinery industry is through their use in the manufacturing of equipment frames and structures. These frames provide the necessary strength and stability to withstand the demanding conditions of agricultural operations. Whether it is in tractors, harvesters, or tillers, steel coils are used to create sturdy and rigid frames that can handle heavy loads, vibrations, and impacts. Additionally, steel coils are used in the fabrication of components such as plow blades, cultivator tines, and seed drills. These components are crucial for soil preparation, seed planting, and crop maintenance. Steel coils provide the necessary strength and resistance to wear and tear, ensuring these components can withstand the rigors of agricultural operations and last for extended periods. Furthermore, steel coils are also used in the manufacturing of hydraulic systems and other moving parts in agricultural machinery. These systems are responsible for powering and controlling various functions, such as lifting, lowering, and steering. Steel coils provide the necessary strength and flexibility for these systems to function optimally, ensuring smooth and efficient operation of agricultural machinery. Moreover, steel coils contribute to the agricultural machinery industry by enhancing the safety and longevity of the equipment. Steel is known for its excellent resistance to corrosion, rust, and extreme weather conditions. By using steel coils in the construction of agricultural machinery, manufacturers can ensure that the equipment remains durable and reliable even in harsh environments, ultimately reducing maintenance costs and improving the overall lifespan of the machinery. In conclusion, steel coils are an indispensable component in the agricultural machinery industry. Their versatility, strength, and durability make them crucial for the manufacturing of equipment frames, components, hydraulic systems, and other moving parts. By utilizing steel coils, the agricultural machinery industry can produce robust and efficient equipment that can withstand demanding agricultural operations, improve productivity, enhance safety, and extend the lifespan of the machinery.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being shaped and cut into the desired size and shape for the door panels. These coils are then formed into the appropriate curvature and attached to the door frame, providing strength, rigidity, and durability to the door structure.

- Q: Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- depends on the amount on nickel used in the manufacturing but mostly yes

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel strapping or bands. They are then placed onto pallets or into crates to protect them during transportation. Additionally, wooden or metal dunnage is often used to separate and stabilize the coils, ensuring they remain intact and in proper condition throughout the shipping process.

Send your message to us

Prepainted Galvanized Steel Plates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords