Prepainted Galvanized Steel Coil-China Best in Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

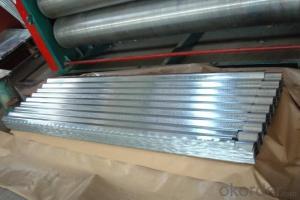

Prepainted Galvanized Steel Coil-China Best in Good Quality

Brief Introduction:

Prepainted Galvanized Steel usually refersto have substrate processed with surface processed and coated then(rollercoated )or bonded organic thin film and baked, and it is able to beprocessed to final prodevtion .

PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board.

Specification:

Thickness:0.15-0.8mm

Width:600-1250mm

Length:on request

Zinccoating: 30-275g/m2

Color:RAL series

Paint:PE, PVDF, PU

Application:

1.Buildings and constructions:roofing, ceilings, gutters, venting lines, indoor decorations,windowframes, etc

2.Electrical appliances:computer shells, washing machines, refrigerators, dehumidifiers,videorecorders, water heaters, etc.

3. Agriculturalequipments: troughs, feeding tools, agricultural driers, irrigation channels,etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Advantages:

1. High strength

2. Well rainproof performance

3. Good corrosion

4. Easy to install and remove

5. FAQ

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the safety precautions when working with steel coils?

- Some safety precautions when working with steel coils include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper lifting techniques to prevent musculoskeletal injuries, maintaining a clear and organized work area to avoid tripping hazards, using proper machinery and equipment to handle and transport the coils safely, and following established safety protocols and procedures. It is also important to receive proper training and supervision to handle steel coils effectively and minimize potential risks.

- Q: I was just thinking, is their a way to make steel qualities inherent in concrete, therefore eliminating the need for re bar?

- Mixing hot steel with liquid concrete would be very hazardous to your health. Steal in a molten state would flash the water in the concrete mix into steam and the steam would blow concrete and steel out of your mold. This would be about like being shot with a shotgun. This occurred in a steel mill near me some years ago on a rainy day when some steel splashed from a ladle and landed on a puddle of water, part of the siding was blown off the building and one worker sent to the hospital.

- Q: The hard industrial steels. If there's a bunch, what's a rough average? Also, what is is measured in?

- There is no average, it depends on the type of steel (hundreds) and the (heat/surface) treatment (infinite possibilities). The Rockwell hardness range covers a large scale so for any given range there is a suffix (C is used for most steel) to denote the selected range. The number is a dimensionless constant that correlates to the strength of the material. Materials can also be surface (case) hardened and then the bulk material will be soft and the surface will be hard, this is typical for items like gears and cams that have rolling wear but are not very heavily stressed to require bulk hardness. Most steel that is hardened is first machined to size and then hardened. If more accuracy is required, they are machined to just over net size, hardened and then ground to the final size as the heat treatment can change the size and shape a little as stresses are released. Some examples: Very hard steel (e.g. a higher quality knife blade): HRC 55–66 Axes, chisels, etc.: HRC 40–45 4140 Cr Mb Steel HRC 28 - 36 , bulk hardened to HRC 54, Nitride case hardened to HRC 60 P20 tool steel can be bulk hardened to over HRC 55 and then tempered down from HRC 51 to 28

- Q: I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- To add to Alex's good answer... ASM Intl now has a book titled Steel Metallurgy for Non-Metallurgist. You can turn metallic meteorites into steel if you add the right amount of Fe and C. That won't make it the strongest but it is possible. I don't think you want the strongest exactly. In general and with swords in particular, you want to be pretty specific about exactly what physical properties you want. Strength and ductility typically vary inversely to each other, higher stength, lower ductility, or lower strength, higher ductility. The issue is related to the idea of a diamond sword. It would be nice and hard but it would probably shatter the first time you stuck anything with it. Swords need a combination of properties, hard so it holds a sharp edge, and tough so it does not fracture, strong so it can be light enough to swing.

- Q: Is steel easier to weld?Which is more brittle/less flexible?

- I can't weld steel to aluminum, and generally speaking I'd say the answer is no, however, there are some special procedures that can make a metallic bond between steel and aluminum, it can be done with explosive welding. A lot of multi-ply cookware is made with aluminum sandwiched between stainless steel, there is so much of it that I imagine there is another way besides explosives, but I don't know what. In any case it is not a normal workshop procedure. Steel is often considerably easier to weld, but it depends on the alloy. some steels are difficult to weld and some aluminum alloys are fairly easy, but on the average steel is easier. as far as brittle/ flexible it again depend on the alloy, some steels are less brittle than some aluminum alloys and the other way around. Steel does have a higher modulus of elasticity, so for a given size steel is stiffer, but that is for elastic deformation, for plastic deformation steel often has a higher yield strength, but some of the more exotic aluminum alloys can be stronger than low grades of steel.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- It depends on the person. Sometimes cold weather makes stretched ears feel tight, like tighter against plugs. I never felt this, and my friends never have either(at least they say they haven't). Go ahead and wear them, but if you feel any discomfort, just change them out.

- Q: What is the minimum temperature that steel coils can withstand?

- The minimum temperature that steel coils can typically withstand is around -40 degrees Celsius.

- Q: I have to explain some functions of stainless steel but after days of searching I cant find an answer. Thankyou in advance for your help :)

- nicely worth little or no so a great way as i'm in contact. It has an somewhat destructive co useful of heat, is confusing to lubricate to maintain the meals from sticking and could strengthen a warm spot somewhat. My decision is a good high quality forged iron, it extremely is heavy yet conducts warmth nicely and spreads it flippantly. Stainless with copper bottoms is marginal for boiling water whether it does sparkling somewhat. There are countless alloys on the industry that are usable as cook dinner ware. Aluminum is worse than stainless. Of the organic metals, copper is the suited conductor of heat, forged iron is my decision, spun metallic does artwork. desire this helps. never wash forged iron cookware with cleansing soap and water.

- Q: What is the market demand for steel coils?

- The market demand for steel coils is influenced by various factors such as construction, manufacturing, and infrastructure development. As steel coils are widely used in industries like automotive, construction, and appliances, the market demand for steel coils is generally high. However, it can fluctuate depending on economic conditions, industry trends, and global demand for steel products.

- Q: i bought an airsoft gun and it said steel recievers on it im not sure what that is

- it means the receivers are made of steel. the receivers on an airsoft gun is pretty much the body of the gun. So pretty much whatever you see on the outside is steel.

Send your message to us

Prepainted Galvanized Steel Coil-China Best in Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords