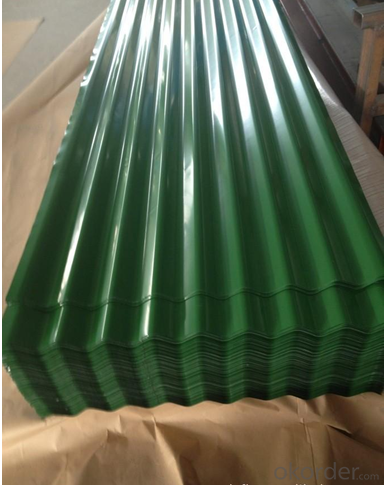

Pre-Painted Steel Coil Thickness 0.3mm-2mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

cold rolled strips

1. width: 19-1500mm

2. thickness :0.2-3.0m,2.0-13.5mm

3.zinc coating:z60-z275

4.GB,JIS,ASTM,DIN,EN

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

Applications:

Pre-painted steel metal products are used in a vast array of applications including:

1.construction industry

2. household appliances

3.automotive

4.industrial applications

5.packaging

FAQ

What is the validity of your quotation?

Normally 2 days.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: What are the different coil coating options available for steel coils?

- There are several coil coating options available for steel coils, including polyester, polyurethane, fluoropolymer, silicone polyester, and plastisol coatings. Each of these options offers different properties such as durability, weather resistance, UV protection, and chemical resistance, allowing for customization based on the specific application and environmental conditions.

- Q: How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of rigorous testing, adherence to industry standards, and effective quality control measures throughout the manufacturing process. This includes conducting various tests such as chemical composition analysis, mechanical property testing, and surface inspection to verify the integrity and durability of the steel coils. Additionally, implementing strict quality control protocols, regular inspections, and continuous improvement initiatives are essential to ensure consistent and high-quality production of steel coils.

- Q: How long do steel coils last?

- The lifespan of steel coils can vary depending on several factors, including usage, maintenance, and environmental conditions. However, with proper care and regular maintenance, steel coils can typically last for several decades.

- Q: What are the common applications of coated steel coils?

- The excellent properties and versatility of coated steel coils make them suitable for a wide range of applications in various industries. Some common uses of coated steel coils include: 1. Construction industry extensively employs coated steel coils for roofing, cladding, and wall panels. The coating ensures long-lasting structures by providing superior corrosion resistance, durability, and weatherability. 2. In the automotive industry, coated steel coils are widely used for manufacturing body panels, bumpers, and chassis parts. The coatings enhance aesthetics, protect against corrosion, and improve paint adhesion for a flawless finish. 3. Coated steel coils find utility in the production of household appliances like refrigerators, washing machines, and ovens. The coatings provide an attractive, smooth finish while protecting the steel from moisture and environmental factors. 4. Heating, Ventilation, and Air Conditioning (HVAC) systems commonly utilize coated steel coils for manufacturing ductwork, air handling units, and heat exchangers. The coatings ensure resistance against corrosion and improve system efficiency. 5. The furniture industry also makes use of coated steel coils for manufacturing cabinets, tables, and chairs. The coatings provide a decorative finish while protecting the steel from wear and tear. 6. Electrical equipment production, including switchboards, control panels, and enclosures, involves the use of coated steel coils. The coatings provide insulation and protection against electrical conductivity, ensuring durability. 7. In the packaging industry, coated steel coils are used for manufacturing cans, containers, and closures. The coatings act as a barrier against moisture and prevent contamination, ensuring the preservation and safety of packaged products. In conclusion, coated steel coils offer corrosion resistance, durability, aesthetics, and protective properties, making them suitable for various applications across industries. From construction to automotive, appliances to furniture, and even in electrical equipment and packaging, coated steel coils play a crucial role in delivering high-quality products and ensuring long-lasting performance.

- Q: What are the dimensions of steel coils used in the construction equipment industry?

- The dimensions of steel coils used in the construction equipment industry can vary depending on the specific application and requirements. However, there are common standard dimensions that are often used. Steel coils used in the construction equipment industry typically have a width ranging from 600mm to 2000mm. The thickness of these coils can range from 0.5mm to 25mm or even higher, depending on the intended use and structural requirements. The weight of steel coils used in construction equipment industry can vary significantly, ranging from a few hundred kilograms to several tonnes. The weight is typically determined by the dimensions and thickness of the coil, as well as the specific grade and type of steel being used. It is important to note that these dimensions are not fixed and can be customized based on the specific needs of the construction equipment industry. Manufacturers and suppliers can provide steel coils in various dimensions to meet the specific requirements of construction equipment manufacturers and contractors.

- Q: What are the dimensions of steel coils used in the building materials industry?

- The dimensions of steel coils used in the building materials industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry typically range from 0.5mm to 3mm in thickness and 600mm to 1500mm in width. The length of the coil can vary depending on the manufacturer and customer specifications. It is also important to note that the weight of the coil can vary, with typical weights ranging from a few hundred kilograms to several tonnes, depending on the size and thickness of the coil. Ultimately, the dimensions of steel coils in the building materials industry are determined by the specific needs and specifications of the construction projects they are intended for.

- Q: What are the common quality issues with steel coils?

- Steel coils commonly have quality issues including surface defects, dimensional variations, mechanical property variations, coating issues, internal defects, edge issues, and coil set or camber. These issues can impact the appearance, performance, processing, and suitability of the final product. To maintain quality, manufacturers employ rigorous inspection, testing, and adherence to industry standards and specifications.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- its faster to build with prefabricated steel materials. if its cheaper or not...im not really sure. but definitely faster

- Q: Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. They are used primarily for the construction of the ship's hull and other structural components due to their strength, durability, and ability to withstand harsh marine environments.

Send your message to us

Pre-Painted Steel Coil Thickness 0.3mm-2mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords