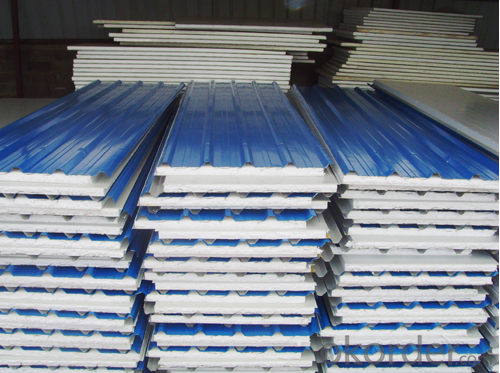

Pre-Painted Steel Coil Thickness 0.9mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prime CGCC RAL DX51D Z60 Z100 Color Coated Steel/ PPGI/Color Prepainted Galvanized Steel Coil(China)

FOB Price: US $630 - 938 / Ton Get Latest Price

Min. Order Quantity: 15 Ton/Tons

Supply Ability: 5000000 Ton/Tons per year

Port: Qingdao, Tianjin, China

Payment Terms: L/C, T/T, Western Union

Contact Supplier

Company Information

Quick Details

Standard: AISI, ASTM, BS, DIN, GB, JISGrade: SGCC SGCD SGCH DX51D/52D/53DThickness: 0.22-1.0 mm

Place of Origin: Tianjin China (Mainland)Model Number: CGCC CGCL PPGI PPGLType: Steel Coil

Technique: Cold RolledSurface Treatment: CoatedApplication: Container Plate

Special Use: Wear Resistant SteelWidth: 750-1250mmLength: Coil Or Sheet (780-6000 mm ) can be done as your requirements.

Exporting Ability: 500 20ft container/each monthZinc Coating: Z40--Z180g/m2Painting: Front side paint thickness: 15-25μ M (bottom paint + top paint)

Sample: Offer Free Sample For Quality TestContainer Info: One 20ft container can hold 26tons MaxColor: As the RAL color chart

Coil I. D: 508/610 mmCoil Weight: 3.5-8 tons/each coilOther Poducts: Cold rolled, galvanized steel coils

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

FAQ

1.What's your MOQ?

25MT, it is for one container.

- Q: Is steel case ammo going to mess the gun up or is it just going to wear the parts out faster and if so how much faster? (I am not planning on reloading the rounds)

- Look at it this way, steel ammo is what about 20 cents per round if you buy it at a gun show by the box of 500. Brass ammo costs like 45 cents per round at my local Academy Sports Outdoors. Now, the life of an AK with military steel case ammo is 25,000 rounds.... lets assume you can get an extra 10,000 by using brass ammo. If you have saved all that money by buying steel cased ammunition, you could buy 3 replacement AK's with the money you saved by the time you wear one out. The AK was made to use steel cased ammunition. All Russian designed weaponry is designed for steel cased stuff, I have heard they actually function better with steel. Something to do with the hardness of the metal.

- Q: What are the common standards and specifications for steel coils?

- There are several common standards and specifications for steel coils that are widely recognized and used in the industry. Some of the most common ones include: 1. ASTM A36/A36M: This specification covers carbon structural steel shapes, plates, and bars of structural quality for use in riveted, bolted, or welded construction. 2. ASTM A572/A572M: This specification covers high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars for applications in bolted, riveted, or welded construction. 3. ASTM A653/A653M: This specification covers steel sheet, zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) by the hot-dip process. 4. ASTM A1011/A1011M: This specification covers hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength steel sheet and strip in coils. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet (galvanized steel sheet) and strip. 6. EN 10111: This European standard specifies the requirements for continuously hot-rolled low carbon steel sheet and strip for cold forming. 7. ISO 3575: This International Organization for Standardization standard specifies the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few examples of the common standards and specifications used for steel coils. It is important to note that different industries and applications may have specific requirements, so it is always advisable to consult the relevant standards and specifications for the specific application.

- Q: What is the average width tolerance for steel coils?

- The average width tolerance for steel coils can vary depending on the specific industry and application. However, in general, the standard width tolerance for steel coils is typically around ±0.005 to ±0.020 inches.

- Q: What are the common coil lengths available for steel coils?

- The common coil lengths available for steel coils vary depending on the industry and specific requirements. However, some standard coil lengths are commonly used across various applications. These include coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths are often used in industries such as construction, manufacturing, and automotive, where steel coils are widely used for various purposes. It is important to note that coil lengths can also be customized based on specific project needs or customer preferences.

- Q: How do we use steel ?plesase answer, its for homework xxx

- Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.Other common applications include shipbuilding, pipeline transport, mining, aerospace, white goods, office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour.

- Q: How do steel coils contribute to the automotive lightweighting trend?

- There are several ways in which steel coils contribute to the automotive lightweighting trend. Firstly, they are used in the production of advanced high-strength steels (AHSS), which offer a higher strength-to-weight ratio compared to traditional steel grades. These AHSS provide the same structural integrity as conventional steel but with less weight. By using AHSS in the construction of vehicle components such as body panels, chassis, and suspension systems, automakers can reduce the overall weight of the vehicle, leading to improved fuel efficiency and lower emissions. Additionally, steel coils are utilized in the manufacturing of tailor-rolled blanks (TRBs). TRBs are created by welding or bonding different steel grades together in a coil before stamping them into the desired shape. This method allows for the optimization of material usage, as stronger steel grades can be strategically placed in areas that require higher strength, while lighter grades can be used in less critical areas. This technique not only reduces weight but also enhances safety by reinforcing necessary areas of the vehicle. Furthermore, steel coils enable the production of thinner and more formable steel sheets. Advances in steelmaking technology have made it possible to develop thinner gauges without compromising strength and durability. Thinner steel sheets are easier to shape and form, making it possible to create complex and lightweight automotive parts. This not only reduces weight but also improves design flexibility and aerodynamics, resulting in enhanced performance and fuel efficiency. Moreover, steel coils contribute to cost-effectiveness in lightweighting efforts. Steel is a relatively affordable material compared to alternatives like aluminum or carbon fiber. By utilizing steel coils, automakers can achieve their lightweighting goals while keeping manufacturing costs under control. This affordability aspect is particularly important in the automotive industry, where cost considerations play a significant role in vehicle design and production. In conclusion, steel coils play a vital role in the automotive lightweighting trend by enabling the production of advanced high-strength steels, tailor-rolled blanks, thinner and more formable steel sheets, and cost-effective lightweight solutions. These advancements contribute to improved fuel efficiency, reduced emissions, enhanced safety, and increased design flexibility, all of which are crucial factors in the ever-changing automotive industry.

- Q: How are steel coils used in the manufacturing of industrial pumps?

- Steel coils are used in the manufacturing of industrial pumps as they are typically used to construct the pump housing and impellers, providing the necessary strength and durability for handling high-pressure fluids and withstanding harsh operating conditions. The steel coils are processed and shaped into various components, ensuring the structural integrity and reliability of the pump, ultimately contributing to its efficient operation and long lifespan.

- Q: What is the process of recycling steel coils?

- To ensure optimal utilization of material and minimize waste, several steps are undertaken in the recycling of steel coils. To begin, steel coils are gathered from a variety of sources, including industrial manufacturing facilities, construction sites, and scrap yards. These coils are then transported to a recycling facility where their quality is thoroughly assessed and the appropriate recycling method is determined. Following this, the steel coils are cleansed to eliminate any contaminants such as dirt, oil, or paint. This cleansing process may involve the use of chemical agents or mechanical procedures, depending on the extent of contamination. The cleansing of the coils is crucial in maintaining the quality of the recycled steel. After the cleansing process, the coils are either shredded or sheared into smaller pieces for easier processing. This step helps to increase the surface area, making it simpler to separate the steel from any other materials that may be present within the coils. Once the coils have been broken down into smaller pieces, they undergo magnetic separation. This entails passing the steel pieces through a magnetic separator that utilizes powerful magnets to attract and separate the ferrous steel from non-ferrous materials like aluminum or plastic. This separation is vital in ensuring the purity of the recycled steel. The separated steel pieces are then subjected to extremely high temperatures in a furnace, causing them to melt. This melting process not only eliminates any remaining impurities but also allows the steel to be shaped into various forms and molds, depending on its intended use. Following the melting process, the molten steel is poured into molds or cast into ingots to solidify. These ingots can be further processed and transformed into new steel products or used as raw material in different industries. Throughout the recycling process, the steel coils are subjected to quality control measures to guarantee that the resulting recycled steel meets the necessary specifications and standards. This includes conducting chemical analyses and mechanical tests to verify the strength, composition, and overall quality of the recycled steel. In conclusion, the recycling of steel coils involves the collection, cleansing, shredding, separation, melting, and molding of the steel to produce new products or raw material. This process not only conserves valuable resources but also reduces the environmental impact associated with traditional steel production.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- Depends okorder

- Q: 1943 steel pennies

- You really don't want to do anything to to them. If they're rusty, that's just the way they are now. Store them in a dry place. Cleaning will do more damage than good, and will hurt the value. If it were possible to undo the damage, our cars would never rust, iron pipes wouldn't pit, and everything would be made of steel. Don't let it worry you, they're still worth having.

Send your message to us

Pre-Painted Steel Coil Thickness 0.9mm Width 900mm-1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords