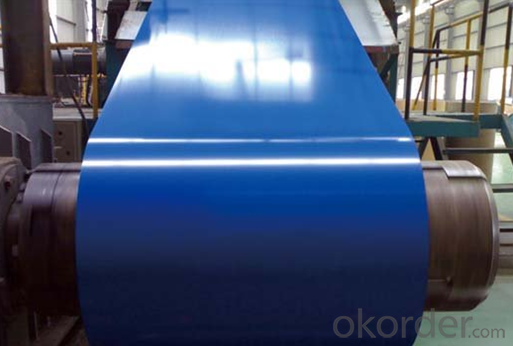

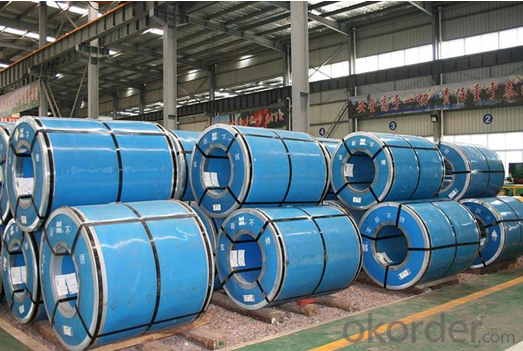

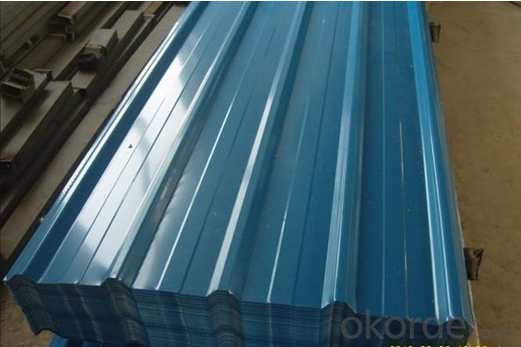

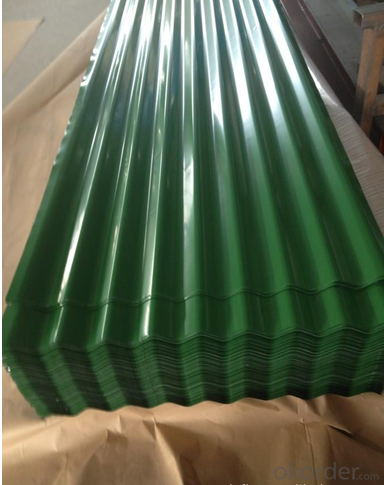

Pre-Painted Steel Coil for Building/Color Coated Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1) Standard: JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

2) Grade:DX51D+Z

3) Thickness: 0.12mm-0.6mm, all available

4) Width: 600mm-1250mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Hardness:Soft,full hard

8) Zinc Coating: 50-150g

9) Paint coating: Top 15-20mirco ,back 7mirco

10) Color series: Sea blue,white grey and all RAL color

PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the dimensions of steel coils used in the appliance industry?

- Steel coils used in the appliance industry can have varying dimensions depending on the specific application and requirements. However, a typical range for these coils is a thickness of 0.015 to 0.035 inches (0.38 to 0.89 millimeters), a width of 24 to 36 inches (61 to 91 centimeters), and a weight between 1,500 to 10,000 pounds (680 to 4,535 kilograms). These dimensions are chosen to facilitate efficient handling, transportation, and processing during the appliance manufacturing process. It is important to verify these dimensions with the manufacturer or supplier for accurate and current information.

- Q: Can steel coils be coated with anti-static materials?

- Yes, steel coils can be coated with anti-static materials. These materials are specifically designed to reduce or eliminate static electricity buildup on the surface of the steel coils, which can be beneficial in various industrial applications where static discharge can cause damage or safety hazards.

- Q: What are the different coil packaging methods used for steel coils?

- Steel coils can be packaged using various methods to guarantee their protection and secure transportation. These methods also help optimize storage space. Some of the commonly used packaging methods for steel coils are as follows: 1. Strapping: Metal or plastic straps are used to secure the steel coils. This ensures stability and prevents unrolling or shifting during transportation. Strapping is suitable for smaller coils or when other packaging methods are also utilized. 2. Stretch wrapping: Steel coils are tightly wrapped using a stretch film. This technique provides excellent protection against dust, moisture, and other contaminants. It also keeps the coils tightly bound and prevents movement during handling and transportation. 3. Steel banding: Steel bands or straps are employed to secure the coils. This packaging method offers superior strength and durability. It is ideal for larger and heavier steel coils that require additional reinforcement. 4. Wooden crating: Particularly large or heavy steel coils are packaged in wooden crates. These crates provide enhanced protection against impacts, moisture, and other external factors. Wooden crating is commonly used for long-distance transportation or when coils need to be stored for extended periods. 5. Coil saddles: Specialized devices called coil saddles are used to package large coils securely. These devices prevent rolling or movement. Coil saddles are preferred when strapping or wrapping is not feasible. 6. Paper interleaving: Sheets of paper are placed between each layer of steel coils to prevent damage caused by friction. This method is commonly used for coils with a high surface finish or those susceptible to scratching. Each of these packaging methods offers distinct advantages and is chosen based on factors such as coil size, weight, transportation requirements, and desired level of protection. By employing these methods, steel coil manufacturers and distributors can ensure the safe arrival of their products in optimal condition.

- Q: I am buying my boyfriend a steel guitar for our one year anniversary and I was curious what brand or company I should look into. I want something high quality yet traditional. Money is not really an issue but I don't exactly want to spend an arm and a leg either.Thank you in advance!

- Did Steel Guitar stand for guitar string ? If yes, there's many brand provide quality guitar string and also be famous brand. you can buy such as D'addario, Errnie ball, GHS, Blue Steel. One more tips, for standard string gauge, if you want to surprise your boyfriend, buy .9 or .10 gauge set. This string set suitable for standard guitar, He'll be more happy if you give him 1 pack of string, buy if it over your price range, just 1 set is ok, haha. Happy Anniversary, Es. ;)

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Broken Steel doesn't begin until the main quest ends.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing using various methods such as visual inspection, magnetic particle inspection, dye penetrant inspection, and ultrasonic testing. These techniques help identify any irregularities or defects on the surface of the coils, ensuring the quality and integrity of the final product.

- Q: What are the dimensions of steel coils used in the energy sector?

- The dimensions of steel coils used in the energy sector can vary depending on the specific application and requirements. However, commonly used dimensions for steel coils in the energy sector range from 0.5mm to 5.0mm in thickness, with widths typically ranging from 600mm to 2000mm. The diameter of the coil can vary as well, with commonly used sizes ranging from 1000mm to 2200mm. These dimensions are chosen to ensure the coils can be easily transported, processed, and utilized in various energy sector applications such as power plants, oil and gas pipelines, and renewable energy projects. It is important to note that these dimensions are not fixed and can be customized based on specific project requirements.

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves several steps to ensure the safe and efficient handling of the coils. 1. Unloading: The steel coils are typically transported to the desired location using cranes or forklifts. They are carefully unloaded from the transportation vehicle and placed in a designated area. 2. Inspection: Before uncoiling, it is crucial to inspect the steel coils for any damage or defects. This step ensures that only quality coils are processed further. 3. Securing: Once inspected, the steel coils are secured to prevent any movement during the uncoiling process. This is done by using clamps or straps to hold the coils firmly in place. 4. Uncoiling: Uncoiling involves the gradual unwinding of the steel coil. This can be done manually or using specialized machinery such as uncoilers or decoilers. The coil is typically fed through a series of rollers that help guide the unwinding process. 5. Straightening: In some cases, the steel coil may need to be straightened before further processing. This can be done using straightening machines that apply pressure to remove any bends or twists in the steel. 6. Cutting: If required, the uncoiled steel coil may be cut into smaller sections or sheets. This can be done using shearing machines or other cutting tools. The dimensions and size of the cuts depend on the specific requirements of the project. 7. Recoiling: Once the desired processing steps are completed, the steel coil can be recoiled. This involves rewinding the steel into a new coil shape. Recoiling can be done manually or using recoilers, which wind the steel evenly and tightly to maintain its integrity. 8. Packaging and storage: After recoiling, the steel coils are typically packaged and stored for further transportation or use. They may be wrapped in protective materials such as plastic or metal sheets to prevent corrosion or damage. Overall, the process for uncoiling and recoiling steel coils requires careful handling, inspection, and the use of specialized machinery. By following these steps, steel coils can be efficiently processed and prepared for various applications in industries such as construction, automotive, and manufacturing.

- Q: Ok, so I'm obsessed with learning how to play the guitar (I preffer acoustic)... I'm a teenage girl that wants to play rock/pop/folk music... I want to learn first how to strum... then eventually how to pick...so what type of string is better? nylon or steel?

- A good number of teachers (in No.California) recommend nylon string guitars for beginner students for the following reasons: 1: Either (nylon strings or steel strings) type of acoustic guitar can play ANY type of music However,nylon strings are much easier (less punishing) on the fingers as well as you start learning to use your fingers (not a pick )to play. Many beginners with the steel-string like to start right away with the use of a pick to avoid the hardness of the steel strings and seldon move up to learn to use the bare fingers to play. 2: For those concern about volume many classical acoustic are built with an electric plug that can be utilize to hook into an amplifiying unit. 3: Once you learn to finger-play you are ahead of some players that started with a pick and have a difficult time to play without a pick. 4: Right hand (if a right-handed)finger dexterity is very important in playing the melody passages (harmony that depends primarily on chords) of any musical piece. 5: It is true that a nylon-string guitar brings out a more mellower sound and the steel-strings have a brighter (but tin-like) sound. Both can be heard clearly in a standard living room environment without need of amplification. In the final analysis is a matter of personal choice. Most of my profesional guitar player friends have and play often both types of guitars. They play the nylon-string when in a group of players and they are assigned the 1st guitar music part. When they are playing harmony (back up) they seem to play more the steel-string instrument. A note of interest: Every player I know that plays classical guitar knows how to sight-read music while most other players that only play with a pick and steel-strings guitar use Tabs for playing. Either way it is you that have to decide. Try both instrument in the same piece of music (or strumm on both) and see which one you like. Good Luck and Enjoy whatever guitar you choose.

- Q: I would like to build steel galvanization plant.

- bcaz of the very corrosive conditions in petrochemical plants, steel without coating doesnt work. coating with zinc (e. g. hot dip galvanizing) help protecting the steel for more time, in simple words , zinc is corroded instead of iron and until there is some zinc on the surface steel is protected. we usualy dont use paint coating bcaz: 1.any porosity in the paint coat result in severe corrosion and steel should be completely coated with paint to be protected ,instead large prosity in zinc coating doesnt matter at all 2. usual painting materials arent proper for the severe corrosive condition ASTM standard( american society for testing and materials) offer world accepted standards for painting quality control

Send your message to us

Pre-Painted Steel Coil for Building/Color Coated Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords