Pre Painted Steel Coil Color Sheets in Ral Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality in China

Caitu USES market mainly into three parts of building, household appliances and transportation, the largest proportion in the construction field, industry and to transport only a fraction of the less.Building general with width, hot dip galvanized steel plate and aluminium zinc steel plate heat as the substrate, mainly processed into corrugated board or with polyurethane accords with sandwich board, used to build the steel structure factory building, airports, warehouses, industrial and commercial buildings, such as the freezer of roof, wall, door.Home appliances color plate general electric galvanized and cold plate as substrate, used in the production of refrigerators and large air conditioning systems, freezers, bread machine, furniture, etc.Transportation on general electric galvanized and cold plate as substrate, is mainly used in the oil pan, car inner decoration, etc.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

Use galvanized steel as substrate layer color coated steel plate, in addition to have the protection of the zinc, zinc layer of organic coating on the cover isolation function, can prevent the steel rust, longer service life than galvanized steel sheet, according to the service life of the coating on the steel plate to 50% longer than galvanized steel.But in the use of different areas and different parts of the same amount of galvanized, same coating, coating thickness of same color coating plate, its service life will be very different.

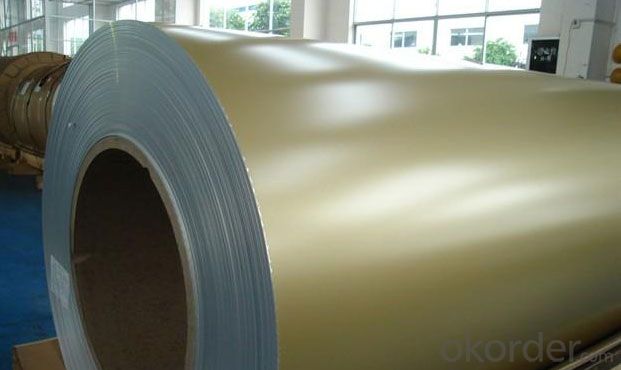

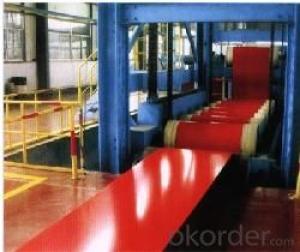

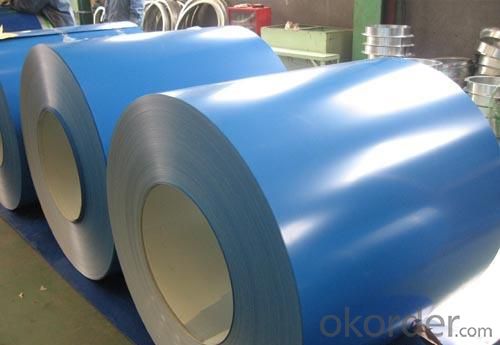

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- If you look at the surface of untreated steel even with a low power microscope you will see a surface that is far from smooth, there are pits and occlusions dotting the surface. Steel is not polished when you see it this way so the only treatment to the surface was the extrusion process or forming done on it by the presses. Iron oxide has a very small particle size and when pulverized into a powder it can easily fill the pits and voids in the steel surface coloring it.

- Q: My remington has a 28 inch barrel and was wondering if it would damage my shotgun to shoot steel out of it?

- Yes, OK for steel. Like Mr. 357 says, with steel shot one size more open is equal to the one size tighter. So the Modified should shoot like a full choke and your improved cylinder should pattern like a modified choke. The Express model came out about the same time steel shot became prevalent and it is fine with steel shot. If I remember correctly we were working on making the data sheets for steel shot around 1988-1989. My hunting buddy and neighbor was the man who first began importing steel shot. Had to figure out a wad to use with it also. And got it Federally mandated for waterfowl hunting.

- Q: What are the different steel coil finishes available?

- There are several different steel coil finishes available, including hot rolled, cold rolled, galvanized, and stainless steel finishes.

- Q: What are the different methods of coil joining for steel coils?

- There are several different methods of coil joining for steel coils, including welding, laser welding, stapling, and adhesive bonding.

- Q: I have samurai sword that is a replica of the kill bill sword. It says on the blade stainless steel, what can i use to shine and protect blade. It had and still does a wax.like coating on the blade sine i received it. Thx for ur help

- Normally okorder

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand varies depending on the specific grade and type of steel being used. Steel is known for its high heat resistance and can typically withstand temperatures ranging from 550°C to 1,100°C (1,022°F to 2,012°F), depending on the grade. However, it is important to note that prolonged exposure to high temperatures can cause steel to lose its structural integrity and result in permanent deformation or even failure. Therefore, it is crucial to adhere to the manufacturer's guidelines and specifications when determining the maximum temperature that steel coils can withstand in specific applications.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Steel coils contribute to strength and durability in manufacturing primarily due to their composition and structural properties. The tightly wound coils are made from high-quality steel, which offers excellent strength, rigidity, and resilience. This enables manufacturers to produce sturdy and long-lasting products, as the steel coils provide a solid foundation and structural integrity to various applications. Additionally, steel coils are often used in the construction of infrastructure, machinery, and automotive industries, where their durability and resistance to wear and tear play a vital role in ensuring the longevity and reliability of the final product.

- Q: What are the different steel coil packaging methods?

- There are several different steel coil packaging methods, including using steel strapping or banding to secure the coils, using plastic or metal end caps to protect the edges of the coils, and using wooden or steel pallets to stack and transport the coils. Additionally, some steel coils may be wrapped in protective film or paper to prevent damage during shipping and storage.

- Q: I have a set of steel pans with copper bottoms. When I cook with oil it always burns the oil to the pan and takes days to clean. I don't think I should use steel wool, since it might scratch the surface. Does anyone know a faster way to clean scorched oil off a steel pan?

- Get a can of Barkeeper's Friend. It's a powdered cleanser. It's gentle enough to be used on a ceramic cook top but still strong enough to get metal clean. Cheap and made from rhubarb leaves! Dampen the pan with water, sprinkle generously and smear around with a sponge with one of those non-stick safe nylon scrub pads. Wait about 10-15 minutes to let the product do some of the work for you. Come back and give it a good scrub. Reapply if necessary. I have all stainless steel cookware and use the Barkeeper's to keep them looking nice; especially since they are on display with my pot rack. I also have some copper pieces used for decoration and I use the Barkeeper's to keep them looking nice. It cleans them up faster and better than any of the homemade concoctions or metal cleaners without the residue. And I do use it on my ceramic cook top too! Be sure to wash and rinse the pan after you get it clean; it does leave a haze if you don't.

- Q: How are steel coils used in the production of steel chains?

- Steel coils are used in the production of steel chains by being unwound and fed into a machine that shapes and forms the individual links of the chain. The steel coils provide the raw material needed to create the strong and durable chains, ensuring they have the necessary strength and integrity for various applications.

Send your message to us

Pre Painted Steel Coil Color Sheets in Ral Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords