Pre-painted Metal Color Coated Aluminium Zinc Steel Coils PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Detail of Pre-painted Metal Color Coated Aluminium Zinc Steel Coils PPGI:

♦ good durability, and can be used longer than galvanized steel ;

♦ good heat resistance, and compared with galvanized steel,under high temperature it does not

discolor easily;

♦ good heat reflecting,good weldability, good adhesion;

♦ machining capability and spraying performance similar to galvanized steel ;

♦ protective film can be provided according to customers’ requirement.

2.Advantages of Pre-painted Metal Color Coated Aluminium Zinc Steel Coils PPGI:

Galvanized steel coil products are mainly applied to building, light industry, automobile, agriculture and animal husbandry fishery. In construction industry, it is mainly used to produce anti-corrosion of industrial and civil building roof, roof grille. In light industries it can be used as appliances shell, civil chimney, kitchenware, etc. Farming fisheries mainly used as food storage, the seafood frozen processing equipment of meat. Business mainly used as materials of storage, packing equipments.

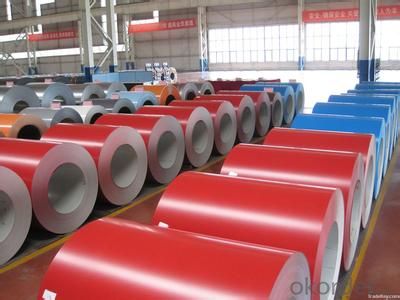

3.Pre-painted Metal Color Coated Aluminium Zinc Steel Coils PPGI Images:

4.Prepainted Galvanized Steel Specification:

Base Material | GI,GL/AZ,EG,CR |

Thickness | 0.2-1.2mm |

Width | 800-1600mm |

Coil ID | 508mm,610mm |

Single Weight | Max 8 M.T |

Metallic Coating | Z60-Z275 or AZ60-AZ180 |

Thickness of organic coating | 20-45micro ( as customer’s requirement) |

Type | Print, embossed,(Wood imitation, Marble, Brush Brick, and Camouflage series, etc) |

Paint | PE , PVDF , SMP , HDP |

Production ability | 80000 M.T per year |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Grade | SGCC, DX5ID, ASTM, EN10142, S350GD, etc |

Application | construction,electrical household appliance,furniture, writing panel, etc |

5.Our Factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils used in the production of steel nails?

- Steel coils are used in the production of steel nails as they serve as the primary raw material. The coils are unwound and fed into a nail-making machine, where they are cut, shaped, and formed into individual nails. This process allows for efficient and consistent nail production, ensuring high-quality and durable nails for various construction and manufacturing purposes.

- Q: What is the average price of a steel coil?

- The average price of a steel coil can vary depending on factors such as the type of steel, size, and market conditions. It is best to consult with suppliers or industry reports for the most up-to-date and specific information on current average prices.

- Q: Can steel coils be coated with chrome?

- Yes, steel coils can be coated with chrome. The process of chrome plating involves the application of a thin layer of chromium onto the surface of the steel coils to enhance their appearance, provide corrosion resistance, and improve their durability.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

- Q: How are steel coils inspected for defects after recoiling?

- Steel coils are inspected for defects after recoiling through a thorough visual examination, which involves inspecting the surface for any visible defects such as scratches, dents, or cracks. Additionally, non-destructive testing techniques like ultrasonic or magnetic particle inspection may be used to identify any internal defects that are not visible to the naked eye.

- Q: What does INOX Steel means?I have been looking up the meaning but cannot find it... please help...

- Inox Steel

- Q: What are the different certifications required for steel coil manufacturers?

- Some of the different certifications required for steel coil manufacturers include ISO 9001, ISO 14001, OHSAS 18001, and various industry-specific certifications such as the American Society for Testing and Materials (ASTM) certifications. These certifications ensure that the steel coil manufacturers meet quality, environmental, and occupational health and safety standards.

- Q: Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. They are often used in the construction industry for various structural components such as beams, columns, and trusses. Steel coils provide strength, durability, and flexibility, making them suitable for supporting heavy loads and withstanding various environmental conditions.

- Q: Is there alloys in low carbon steel or non

- Stainless Steels are alloys that are made up of iron and generally contain around 11.5% chromium. For obtaining special properties, nickel, carbon, chromium, and other elements can be added to it. There are four types of Steel : Carbon Steel Alloy Steel Stainless Steel Tool Steel From kitchen utensils to cutlery, sinks to machine drums, as well as microwave oven liners mainly, use Stainless Steel. One can find different types of products such as Stainless Steel Tube Fittings, Pipe Fittings, Flanges, pipes, Tubes, Fasteners, Sheets, Rods, Bars and so forth are used in different industries. List of typical applications of these Stainless Steel products include: Oil and gas equipments Offshore technology Seawater desalination plants Chemical industry Bridges Storage tanks Medical Industry Civil Engineering Pressure vessels, reactor tanks, and heat exchangers Rotors, impellers and shafts Power plants Petrochemical Shipbuilding industry

- Q: What are the common welding methods used for steel coils?

- There are several common welding methods used for steel coils, depending on the specific requirements and applications. Some of the most widely used methods include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses an electrode coated in flux to create an arc between the electrode and the base metal. This method is commonly used for its simplicity and versatility, making it suitable for a wide range of steel coil welding applications. 2. Gas Metal Arc Welding (GMAW): Also known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. This method is favored for its high welding speed and excellent control over the welding process. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed tubular electrode filled with flux to protect the weld pool. This method is often preferred for its high deposition rates and ability to weld thicker steel coils, making it ideal for heavy-duty applications. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas shield to protect the weld pool. This method is commonly used for its precise control, high-quality welds, and ability to weld thin materials. 5. Submerged Arc Welding (SAW): SAW involves the formation of an arc between a continuously fed wire electrode and the steel coil, while a granular flux covers the arc and weld area. This method is frequently used for its high productivity and ability to weld thick materials. Each of these welding methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the steel coil, desired welding speed, weld quality, and application requirements.

Send your message to us

Pre-painted Metal Color Coated Aluminium Zinc Steel Coils PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords