Pre-Painted Galvanized Steel Sheet,Coil with High Quality White Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

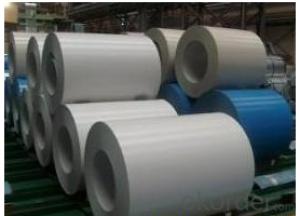

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they are rolled and formed into the required shapes and sizes to create the structural components of the towers. The coils are processed and cut into specific lengths, which are then welded or bolted together to construct the tower sections. The robustness and strength of steel make it an ideal material for transmitting large amounts of electricity over long distances, ensuring the stability and reliability of power transmission towers.

- Q: I am going to be working as a mechanic at my school and I just wanted to know if I should get the steel toe boots or regular. I heard that steel toe boots can be dangerous and uncomfortable. The mechanics recommended getting steel toe to be safe but i'm not sure.

- Steel toe boots they protect your feet and toes a lot better and if u are going to be working they would be better to have than soft toe boots

- Q: What are the common coil finishes available for steel coils?

- Steel coils can be finished in various ways to serve different purposes and achieve different aesthetic appearances. Some popular coil finishes include: 1. Hot-dip galvanized: By immersing the steel coil in molten zinc, a protective layer is formed on its surface. This finish is ideal for outdoor applications like roofing, fencing, and automotive parts due to its excellent corrosion resistance. 2. Galvannealed: Achieved by annealing the hot-dip galvanized coil, this finish gives a matte gray appearance. Galvannealed coils have enhanced paint adhesion, making them suitable for subsequent painting or powder coating in applications like appliances and furniture. 3. Electro-galvanized: A thin layer of zinc is electroplated onto the surface of the steel coil in this process. Electro-galvanized finishes offer good corrosion resistance and are commonly used indoors, such as in electrical enclosures, HVAC systems, and automotive components. 4. Pre-painted or coated: These finishes involve applying a layer of paint or a coating system to the steel coil, improving its appearance and providing extra protection. Pre-painted coils are extensively used in construction, appliances, and automotive industries due to their aesthetic appeal and corrosion resistance. 5. Bare or mill finish: This refers to the untreated, raw steel coil without any additional coatings or finishes. Bare steel coils are commonly used in applications where corrosion resistance is not the main concern, such as structural components, pipes, and tubes. These are just a few examples of the many coil finishes available for steel coils, each offering unique properties and advantages depending on the intended use. Carefully considering the specific requirements of the application is important when choosing the most suitable coil finish.

- Q: How are steel coils used in the production of heating and cooling systems?

- Steel coils are used in the production of heating and cooling systems as they serve as the primary component for heat transfer. These coils are designed to efficiently transfer heat or cool air, allowing for the effective regulation of temperature in heating and cooling systems.

- Q: what is the chemical process that makes steel harder when it is heated and cooled rapidly?what does the heating of it do to the atoms?what does the cooling of it do to the atoms?what makes tempered steel so strong compared to untempered steel?

- You can't temper all steels. Generally the material must be a high-carbon or tool steel. Different alloys temper differently, and tempering is usually done to get a specific set of characteristics, so you must know what you are working with and use the right methods and temperature. If you do it wrong, the material may be hard but too brittle for the purpose or have other issues. It can be simple, such as heating to a dull red, carbonizing the surface (use an acetylene rich flame until it blackens the surface) and oil quenching. Do that to a piece of tool steel (like a screwdriver) and it will case (surface) harden it to the point you can't scratch it with a file. Tempering changes the way the molecular structure in the metal is linked and oriented.

- Q: How are steel coils used in the production of roofing sheets?

- Steel coils are used in the production of roofing sheets by being processed through a series of steps, including rolling, cutting, and shaping. The steel coils are uncoiled and then passed through a roller system to flatten and shape them into thin sheets. These sheets are then cut to the desired length and width. Finally, they undergo various treatments, such as galvanization or coating, to enhance their durability and resistance to corrosion. Overall, steel coils serve as the primary raw material for manufacturing high-quality roofing sheets.

- Q: What are the different types of steel coil transport methods?

- There are several different types of steel coil transport methods, including flatbed trucks, coil racks, coil cradles, and coil trailers. Each method offers unique advantages and is used based on factors such as coil size, weight, and transportation requirements.

- Q: How are steel coils measured for thickness?

- Steel coils are measured for thickness using a variety of methods. One common method is using a micrometer, which is a precision measuring instrument that accurately determines the thickness of the coil. The micrometer is gently pressed against the surface of the coil and the measurement is taken. Another method involves using a thickness gauge, which is a handheld device that can quickly and accurately measure the thickness of the steel coil. The gauge is placed on the coil's surface and the thickness is displayed on a digital screen. In some cases, ultrasonic thickness testing is used to measure the thickness of steel coils. This method involves using ultrasonic waves that are emitted from a handheld device. The waves travel through the coil and bounce back to the device, providing an accurate measurement of the thickness. Regardless of the method used, it is important to ensure that the measurements are taken at multiple points across the coil to account for any variations in thickness. This ensures that accurate and reliable measurements are obtained.

- Q: I have heard that heating the steel and applying oil will help with corrosion, and will give that aged look. I would like to know finishes available without painting. thanks

- Windex works the suited. makes it seem purely like a mirror. if it quite is dingy their is those products that they sell in supermarkets and motor vehicle automobile areas shops observed as brasso it gets the annoying deposits out.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- *Carbon steel, also called plain carbon steel or Mild Steel, is steel where the main alloying constituent is carbon. The AISI defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. If it crosses limit as said, it will come under alloy steel. ASTM A 106 gr B is a carbon steel pipe and seamless Pipe for High Temperature Service. So, it will be a mild steel comes under carbon steel category.

Send your message to us

Pre-Painted Galvanized Steel Sheet,Coil with High Quality White Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords