Pre-Painted Galvanized/Aluzinc Steel Coil Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

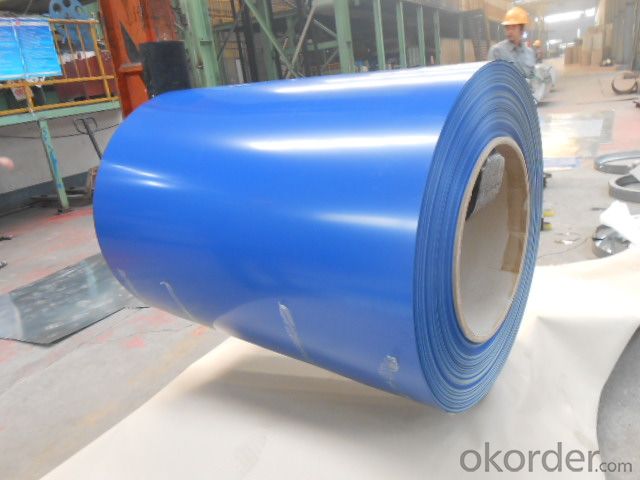

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: How are steel coils used in the production of metal enclosures?

- Steel coils are widely used in the production of metal enclosures due to their versatility and strength. These coils, which are typically made from high-quality steel, serve as the primary raw material for manufacturing metal enclosures. Firstly, the steel coils are unrolled and flattened to the desired thickness using specialized machinery. This process ensures that the coils are in a suitable form for further processing. The flattened steel is then cut into specific sizes and shapes, depending on the design requirements for the metal enclosure. Next, the cut steel pieces are formed into the desired shape using various techniques such as bending, folding, and welding. These processes allow the steel to be molded into the required dimensions and structure of the metal enclosure. The inherent strength and durability of the steel coils ensure that the final product is sturdy and can withstand external forces or impacts. Additionally, steel coils can be coated with protective layers such as galvanization or powder coating to enhance their resistance to corrosion, rust, or other environmental factors. This coating helps to prolong the lifespan of the metal enclosure and maintain its aesthetic appeal. Moreover, the use of steel coils in the production of metal enclosures allows for customization and flexibility. The coils can be easily manipulated to create complex shapes or designs, enabling manufacturers to cater to specific customer requirements. This adaptability makes steel coils a preferred choice in industries such as automotive, electronics, and construction, where metal enclosures are widely used. In summary, steel coils play a crucial role in the production of metal enclosures by providing a strong and versatile raw material. These coils are transformed into the desired shape and size, ensuring the durability and functionality of the enclosures. With their customizable nature and protective coatings, steel coils offer a cost-effective solution for manufacturing high-quality metal enclosures.

- Q: How does coil slitting work?

- Coil slitting is a process used in manufacturing industries to cut large coils of material, such as metal, into narrower strips of desired widths. The coil is unwound and passed through a set of circular blades that make precise cuts along the length of the coil. The blades can be adjusted to the desired width, and the process continues until the entire coil is slit into multiple smaller coils or strips.

- Q: What are the different surface treatments applied to steel coils?

- Some different surface treatments applied to steel coils include galvanizing, electroplating, painting, and powder coating. These treatments help to protect the steel from corrosion, improve its appearance, and enhance its durability for various applications.

- Q: How do steel coils contribute to structural integrity in buildings?

- The role of steel coils in ensuring the structural integrity of buildings cannot be overstated. They play a vital role in multiple ways. To begin with, steel coils are extensively utilized in the construction industry to manufacture essential building components like beams, columns, and trusses. These components are responsible for providing support and stability to the overall structure. Due to their exceptional tensile strength and durability, steel coils guarantee that these components can withstand heavy loads and maintain their structural integrity over an extended period. This is particularly crucial in buildings with multiple floors or large open spaces, where the structural elements need to bear substantial weight without deforming or collapsing. Moreover, steel coils are also instrumental in reinforcing concrete structures. Reinforced concrete is a widely adopted construction technique, and steel coils, in the form of reinforcement bars or mesh, are embedded within the concrete to counteract tensile forces. While concrete excels at withstanding compressive forces, it is weak in tension. By incorporating steel coils, the composite material gains the ability to resist both compression and tension, thereby enhancing its structural integrity. This reinforcement technique is particularly vital in high-rise buildings or structures subject to seismic activity, where the risk of structural failure due to bending or cracking is heightened. Another significant contribution of steel coils to structural integrity lies in their corrosion resistance properties. Steel coils are often coated with protective layers, such as zinc through galvanization or paint, to prevent corrosion caused by moisture, chemicals, or environmental factors. Corrosion weakens the structural integrity of steel, leading to degradation and potential failure. By utilizing corrosion-resistant steel coils, the lifespan of the building is prolonged, and the risk of structural damage is significantly diminished. Furthermore, steel coils offer tremendous versatility in design and construction. Their flexibility and malleability allow for the creation of complex and intricate building structures, enabling architects and engineers to push the boundaries of design while maintaining structural integrity. Steel coils can be shaped, bent, and welded into various forms, making them an ideal material for constructing innovative and aesthetically pleasing buildings. In conclusion, steel coils are indispensable in ensuring the structural integrity of buildings. Their strength, stability, durability, corrosion resistance, and design versatility make them an essential material in modern construction, guaranteeing the safety and longevity of buildings for years to come.

- Q: how many persent of manganese in all types of carbon steel

- No problem with other answers but there is a high carbon/manganese steel called Hadfields Steel which has been used as armour plate in pilots seats in fighter aircraft in the second world war.This steel contains about 13% manganese and about 1.5 % carbon and is non-magnetic because it retains it's high temperature crystal type(austenite).When it is stuck with a bullet it absorbs the energy of the strike by changing crystal structure to the magnetic form of iron(in this case shock Martensite),I should think that it still has a role in the scoops and picks in earth-moving and farming blades.Well you did ask about all types of carbon steel!

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using stickers or tags that contain information such as the coil number, dimensions, weight, grade, and other relevant details.

- Q: How are steel coils used in the automotive industry?

- Steel coils are used in the automotive industry to manufacture various components such as car bodies, frames, and structural parts. The coils are first processed by being uncoiled, flattened, and then cut into the required shapes. These steel components provide strength, durability, and rigidity to vehicles, ensuring safety and structural integrity.

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- This Site Might Help You. RE: Does folding modern steel do anything to enhance a sword? I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the...

- Q: Cold rolled steel coil steel, what is the difference?

- Hot rolling is made of slabs (mainly continuous billets) as raw materials. After heating, strips are made from roughing mills and finishing mills.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords