Pre-painted Galvanized Steel Coil for Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Defination of Prepainted Galvanized Steel Coil

Pre-painted coils are produced by coating a layer of paint on the surface of cold rolled, galvanized or galvalumed coils. Aesthetic appeal and durability are the key festures of color coated steel coil. A wide selection of colors is available to the customer and paints designed to meet specific end use could be specified.

2. Applications of Prepainted Galvanized SteelCoil

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

3. Specifications of Prepainted Galvanized SteelCoil

Standard: ASTM;ASTM;JIS;GB

Grade: SGCC;(DX51D)

Thickness: 0.12-1.2mm

Width: 750-1250mm

Length: Coil or customer's requirements

Zinc Coating: 60-140g/m2

Painting : Top side from 15-25um; Bottom side from 5-10 um

Color : RAL numbers or customers' sample color

Application: building trade, electric apparatus, furniture and transport service

Production arts and crafts : Double coated double drying

Coil ID: 508mm

Coil Weight: 3-6 Ton

Type :coil

Packaging Detail: Fully seaworthy export packing with paper tube or as per customer's requirements

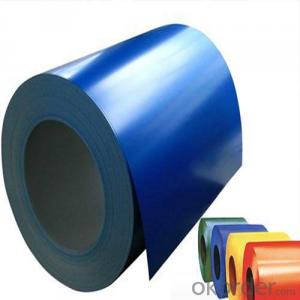

4. Prepainted Galvanized Steel Coil Images

5. Advantages of Our Prepainted Galvanized SteelCoil

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

6. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil surface defects?

- There are several different types of steel coil surface defects that can occur during the manufacturing or handling process. Some of the common types include: 1. Rust: Rust is a common surface defect that occurs when the steel coil is exposed to moisture or oxygen. It appears as a reddish-brown discoloration on the surface of the coil. 2. Scratches: Scratches are superficial marks that can occur during handling or transportation of the steel coil. They can vary in depth and severity, ranging from light surface scratches to deep gouges. 3. Stains: Stains are another type of surface defect that can occur due to exposure to chemicals or other substances. They can appear as discolored patches on the surface of the coil, and may be difficult to remove. 4. Roll marks: Roll marks are impressions or indentations that can occur during the rolling process. They are caused by uneven pressure or misalignment of the rolls, and can appear as lines or patterns on the surface of the coil. 5. Edge wave: Edge wave is a defect that occurs when the edges of the coil are not perfectly flat. It can cause the edges to appear wavy or uneven, and may affect the overall appearance and performance of the coil. 6. Oil spots: Oil spots are surface defects that occur when oil or lubricants used in the manufacturing process are not properly removed. They can appear as dark spots or patches on the surface of the coil, and may affect the adhesion of coatings or paints. 7. Pitting: Pitting is a defect that appears as small, shallow depressions or pits on the surface of the coil. It can be caused by factors such as corrosion, uneven cooling, or impurities in the steel. 8. Holes: Holes are more severe surface defects that can occur due to a variety of reasons, such as corrosion, mechanical damage, or manufacturing errors. They can range in size and can significantly affect the structural integrity of the coil. It is important to address these surface defects promptly to ensure the quality and performance of the steel coil. Regular inspections, proper handling, and appropriate surface treatments can help minimize the occurrence of these defects.

- Q: How are steel coils stored?

- Steel coils are typically stored in warehouses or outdoor storage yards. They are usually stacked on top of each other in a crisscross pattern to maximize space utilization and prevent them from rolling. Additionally, steel coils may be secured with steel banding or placed on pallets to ensure stability during storage and transportation.

- Q: What are the dimensions of steel coils used in the industrial machinery industry?

- The dimensions of steel coils used in the industrial machinery industry can vary depending on the specific application and requirements. However, generally speaking, steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The inner diameter of the coil, known as the core, can range from 508 to 762 millimeters (20 to 30 inches). Additionally, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may be subject to variations based on the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

- Q: Why are properties of steel not identical?

- Steel is manufactured to different specs. To match the needs of its intended end use .Tensel strength,Hardness, Corosion resistance etc. The chemical make up will change to suit.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through visual inspection, magnetic particle inspection, or ultrasonic testing. Visual inspection involves examining the surface for any visible defects such as scratches, dents, or corrosion. Magnetic particle inspection uses magnetic fields and iron particles to detect surface cracks or defects that may not be visible to the naked eye. Ultrasonic testing involves using high-frequency sound waves to detect internal and surface defects in the steel coils. These inspection methods help ensure the quality and integrity of the steel coils before they are further processed or delivered to customers.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- NAFTA became a unfastened commerce contract it is fairly a lot a republican proper. unfastened markets are a sturdy element. each and every so often unfastened markets deliver approximately the shortcoming of jobs in one sector yet that would not advise unfastened commerce is undesirable. opposition like that ensures that capital is spent in it is best way. Proping up death industries isn't a sturdy concept. i know it is not a favored element to declare, even though it is the certainty. would desire to we've propped up the horse and carriage marketplace while autos got here alongside so as that horse handlers did not lose thier jobs? in all risk not. unfastened commerce is a sturdy element. That being mentioned, i don't think of that Obama will merely blanketly wipe out any coverage by means of fact it became a Bush coverage. he isn't that stupid. If it became a sturdy coverage that labored, i'm particular it will be retained.

- Q: How are steel coils used in the manufacturing of signage?

- Steel coils are used in the manufacturing of signage as they serve as the base material for creating durable and sturdy sign structures. These coils are shaped, cut, and processed into various sign components, such as frames, brackets, and supports, which provide stability and strength to the signage. Additionally, steel coils can be coated or painted to enhance the appearance and protect the signage from corrosion, making them ideal for outdoor applications.

- Q: So I want to get my 3+ wood shafted with a dynamic gold shaft because i need a stiffer shaft but dont want to spend much on it.I've never swung a steel shafted wood, but I hear that it is more consistent that graphite....Plus, since the cost of steel is only $15 compared to the $65 graphite, not to mention installation charges.So yeah...... How good is steel for fairway woods?BTW, my swing speed is about 95 but i can amp it up to 110 (with control, that is)

- i take advantage of a three timber off the tee while a motive force could bypass in the process the fairway on a dogleg, or while the fairway gets narrower the further you hit it. Use it to get as close to to a par 5 in 2 as i will, or perhaps even attain a par 5 in 2. Use it to make up floor in case you permit out a rigidity, every time the photos demands me to hit it between 220 and 235 it quite is approximately how some distance I hit my 3 timber. I additionally carry a 5 timber which I hit approximately 2 hundred to 215 and extremely severe so it lands comfortable. i do no longer carry any hybrids regardless of the undeniable fact that as I nevertheless like to hit long irons.

- Q: Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials.

- Q: What are the common defects found in uncoiled steel coils?

- Some common defects found in uncoiled steel coils include surface defects such as scratches, dents, or pits, edge defects like burrs or slivers, and dimensional defects such as variations in thickness or width. Other defects may include coil set (curvature), coil breaks (cracks or fractures), or oil stains. These defects can affect the quality and performance of the steel and may require further processing or inspection before use.

Send your message to us

Pre-painted Galvanized Steel Coil for Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords