Pre-painted Galvanized Steel Coil for Decoration Molding Corrosion Resisitance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Pre-painted Galvanized Steel Coil Description

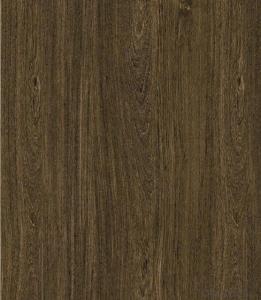

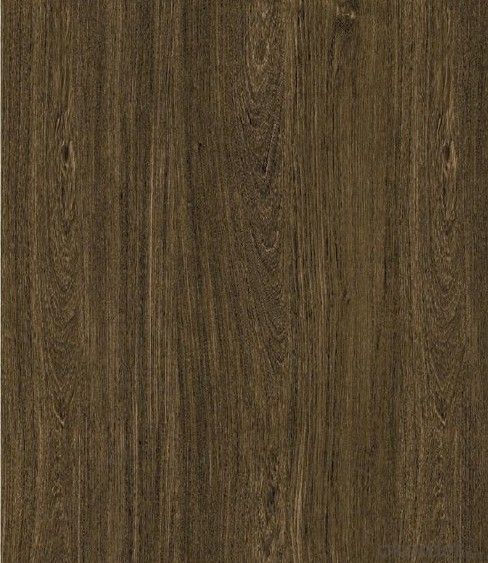

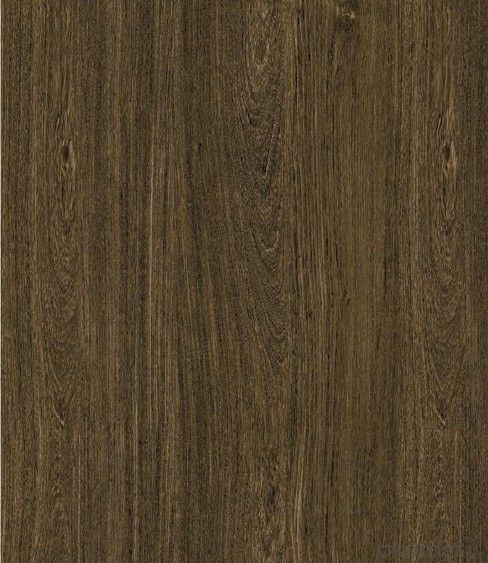

Evevry color by order. With GI as base metal, after pretreatment an liquid dope with seceral layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel.

MC101design pre-painted galvanized steel coil with high zinc coating/camouflage design ppgi used for the army made in China

Main Features of the

. Flexible and durable

. light and easy to transport

. Fast delivery

. Item shipped from Dubai warehouse

Images

Specification

prepainted galvanized steel sheet in coil

Thickness: 0.12-0.8mm

Width: 700-1250mm

Length: On Request

BASE MATERIAL (1)HDGI (2)ALUZINC (3)CR (4)ALUMINUM

GRADE SGCC, DX51D, ASTM A653, EN10142, S350GD,etc.

THICKNESS 0.18mm-0.80mm

WIDTH ≤1250mm

ZINC COATING 60-200g/m2

PATTERN Wood,Marble,Hairline,Brick,and Camouflage series,etc.

PAINT PE,PVDF,SMP,HDP

COIL ID 508mm

COIL WEIGHT ≤6t

FAQ of

. Flexible and durable

. light and easy to transport

. Fast delivery

Packagingwood film laminated steel VCM PPGI manufacturer price standard export packing ,4 eye bands and 4 circumferential bands in steel,galvanized metal and waterproof paper around circumference and bore protection

Delivery Detail Within 20 Days From Receiving Original 30% TT

- Q: What are the different methods of annealing steel coils?

- The different methods of annealing steel coils include full annealing, process annealing, spheroidize annealing, and stress relief annealing.

- Q: How are steel coils used in the manufacturing of engine components?

- Steel coils are used in the manufacturing of engine components as they provide a strong and durable material for various parts. These coils are typically processed and shaped into specific components such as pistons, crankshafts, cylinder heads, and connecting rods, which are vital for the proper functioning of an engine. The high strength and heat resistance of steel make it an ideal choice for these critical components, ensuring the engine's reliability and performance.

- Q: Why is steel so important? How does it help us in everyday life?

- steel comes from iron. Iron is a natural resource and is abundent in nature. so being able to turn it into steel means it can be used for alllll sorts of things! from buildings, cars, piping and tubes, to washing machines, appliances and many other things. its used in our everyday life and is a great, strong material.

- Q: So, I'm looking into steel toe paddock boots. I'll be using them around horses, horses that I don't know and that are rescue horses. I'm currently looking at Equitector the Moorland paddock boots. They're $200, and I think I have to order them online. I like boots that are this style (the Moorland style)... Is there any other brand of boots that has steel toe paddock boots, that are cheaper or that I can buy in stores?

- I bought a pair of plain old Dublin paddock boots from my local tack shop for about $50. I'm not sure if they're steel toed, but I've been stepped on countless times by big quarter and draft horses and never been hurt by it. I'd say, even when working with unfamiliar horses, any good quality paddock boot that fits will be fine, so don't worry about the expensive ones.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are processed for cutting to length or blanking through a series of steps. First, the coil is uncoiled and flattened to remove any inherent deformities. Then, the edges are trimmed to ensure uniform width and straightness. Next, the coil is fed into a leveling machine to eliminate any remaining inconsistencies in thickness. Once leveled, the steel is conveyed to a cutting machine where it is precisely cut into individual sheets of desired length or blanks. These sheets or blanks are then stacked and prepared for further fabrication or distribution.

- Q: How do steel coils resist corrosion?

- A combination of factors contributes to the corrosion resistance of steel coils, including the presence of protective coatings, the utilization of corrosion-resistant alloys, and the implementation of proper handling and storage practices. Galvanization, which involves the application of zinc coatings, is the most common method employed to prevent corrosion in steel coils. This process establishes a barrier between the steel and its surroundings, effectively shielding it from moisture and corrosive elements. The zinc coating acts as a sacrificial layer, taking the brunt of the corrosion instead of the steel itself. Another approach to enhance corrosion resistance entails the use of corrosion-resistant alloys. These alloys are specifically designed to endure harsh conditions and are composed of elements like chromium, nickel, or molybdenum. Upon exposure to the environment, these alloys form a passive oxide layer on the surface of the steel, serving as a protective shield against corrosion. In addition, proper handling and storage practices are crucial in preventing corrosion. It is important to store steel coils in dry and well-ventilated areas to minimize contact with moisture. Care must also be taken to avoid contact with other metals and materials that could result in galvanic corrosion. Regular inspections and maintenance are essential for promptly identifying and addressing any signs of corrosion. In conclusion, the resistance of steel coils to corrosion is achieved through the implementation of protective coatings, the utilization of corrosion-resistant alloys, and the application of proper handling and storage practices. By employing these measures, the longevity and durability of steel coils are ensured in diverse environments.

- Q: What are the dimensions of steel coils used in the building materials industry?

- The dimensions of steel coils used in the building materials industry can vary depending on the specific requirements of the project. However, common dimensions for steel coils in this industry range from 0.15mm to 3.5mm in thickness and 600mm to 2000mm in width. The length of the coils can also vary, typically ranging from 1000mm to 6000mm.

- Q: Can steel coils be recoiled?

- Yes, steel coils can be recoiled. Recoiling involves rewinding a coil of steel to a smaller diameter, often to improve handling and transportation.

- Q: What are the common problems encountered with steel coils during production?

- There are several common problems encountered with steel coils during production. One of the most common issues is coil slippage, where the coils shift or slide out of place during handling or transportation. This can result in damage to the coils or pose a safety risk to workers. Another common problem is coil rusting or corrosion. Steel coils are susceptible to rusting if they come into contact with moisture or are not properly protected. Rust can compromise the structural integrity of the coils and lead to product defects or failure. Coil breakage is also a common problem. This occurs when the coils are subjected to excessive stress or tension, causing them to crack or break. Coil breakage can result from improper handling or storage, as well as production issues such as improper rolling or cooling processes. Coil surface defects are another common issue. These defects can include scratches, dents, or uneven surfaces on the coils. Surface defects can compromise the appearance and quality of the final product, making it unsuitable for certain applications. Lastly, coil contamination is a problem that can occur during production. Contaminants such as dirt, oil, or foreign particles can adhere to the surface of the coils, leading to quality issues or difficulties in further processing. Contamination can result from improper handling, inadequate cleaning processes, or poor environmental control. To mitigate these common problems, proper handling and storage practices are essential. This includes using appropriate lifting and transporting equipment, ensuring the coils are stored in a dry and clean environment, and implementing effective rust prevention measures. Regular inspections and quality control checks can also help identify and address any issues early on, preventing further damage and ensuring the production of high-quality steel coils.

- Q: Can i make holes in iron and steel with somekind of drill bit. All i have is metal drill bits. Mabey like 68 of them but i dont know wich one to use and if they will penetrate.

- Drills are used to make holes in steel all the time.

Send your message to us

Pre-painted Galvanized Steel Coil for Decoration Molding Corrosion Resisitance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords